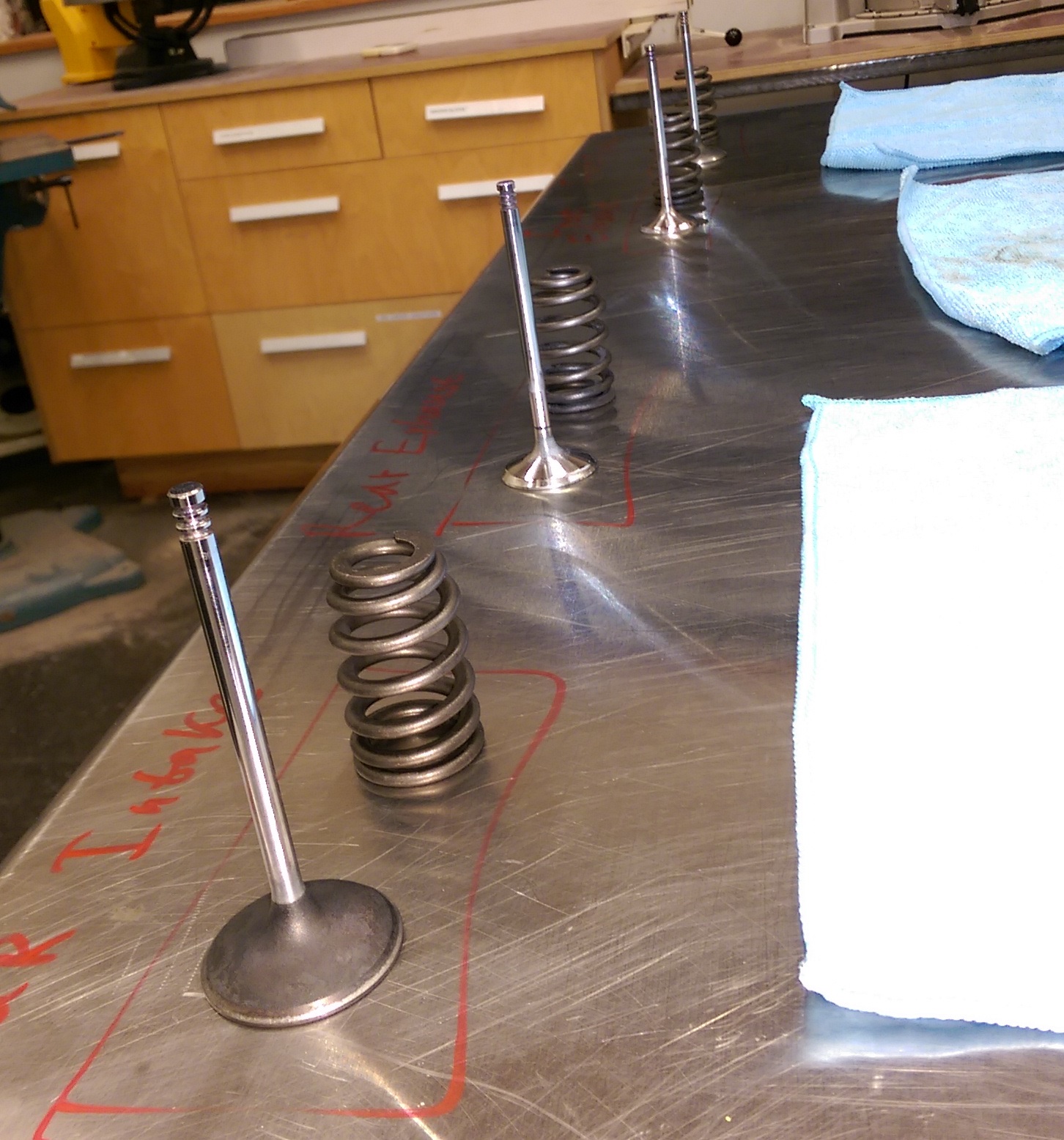

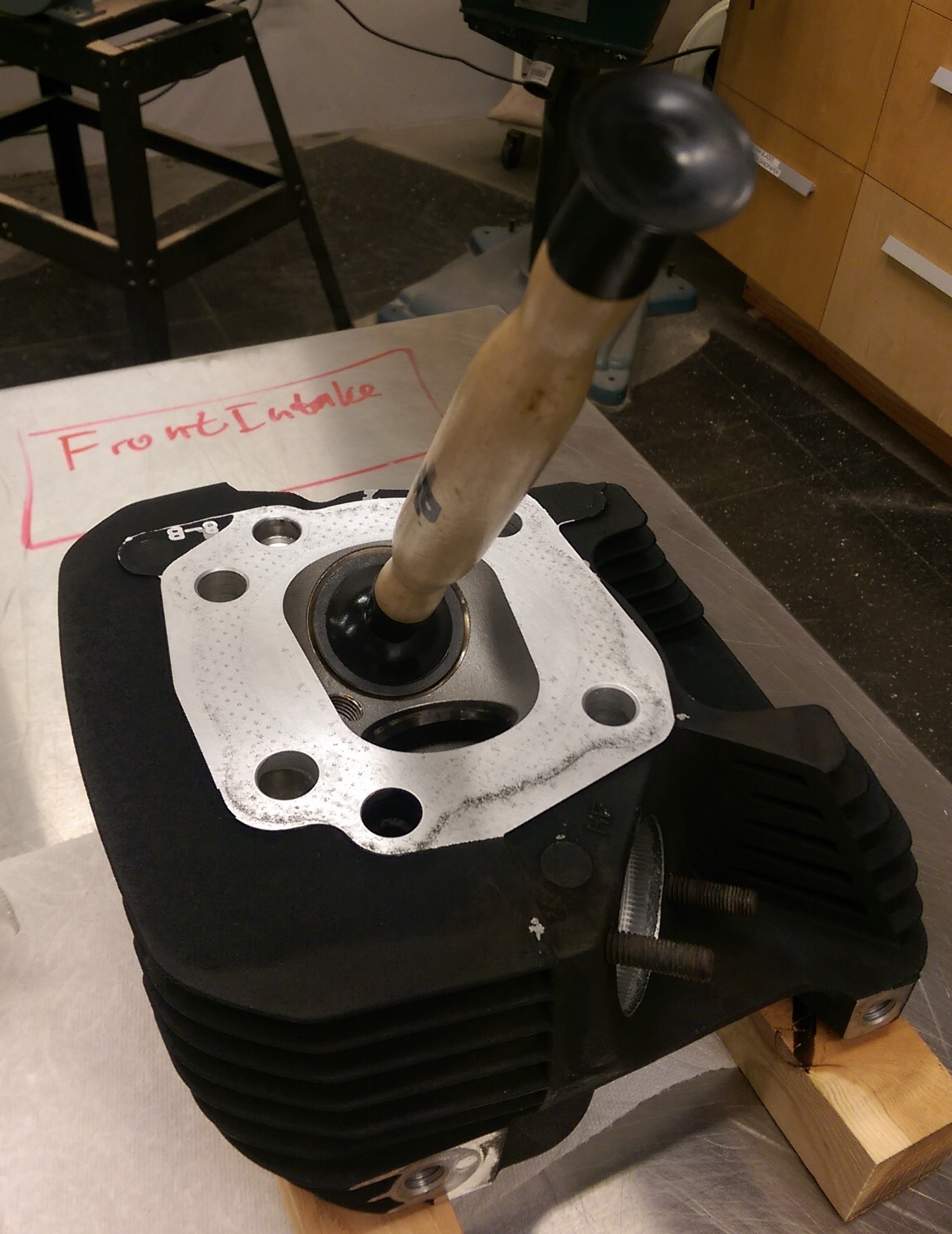

Today I'm going to show you how to clean and polish valve guide outside surface.

If your motorcycle has many miles and you want to replace valve seals you probably will not be able to do this easily. The valve seal likely will be sticked on the valve guide with no any chance to be removed by bare hand with no tools even manual says opposite.

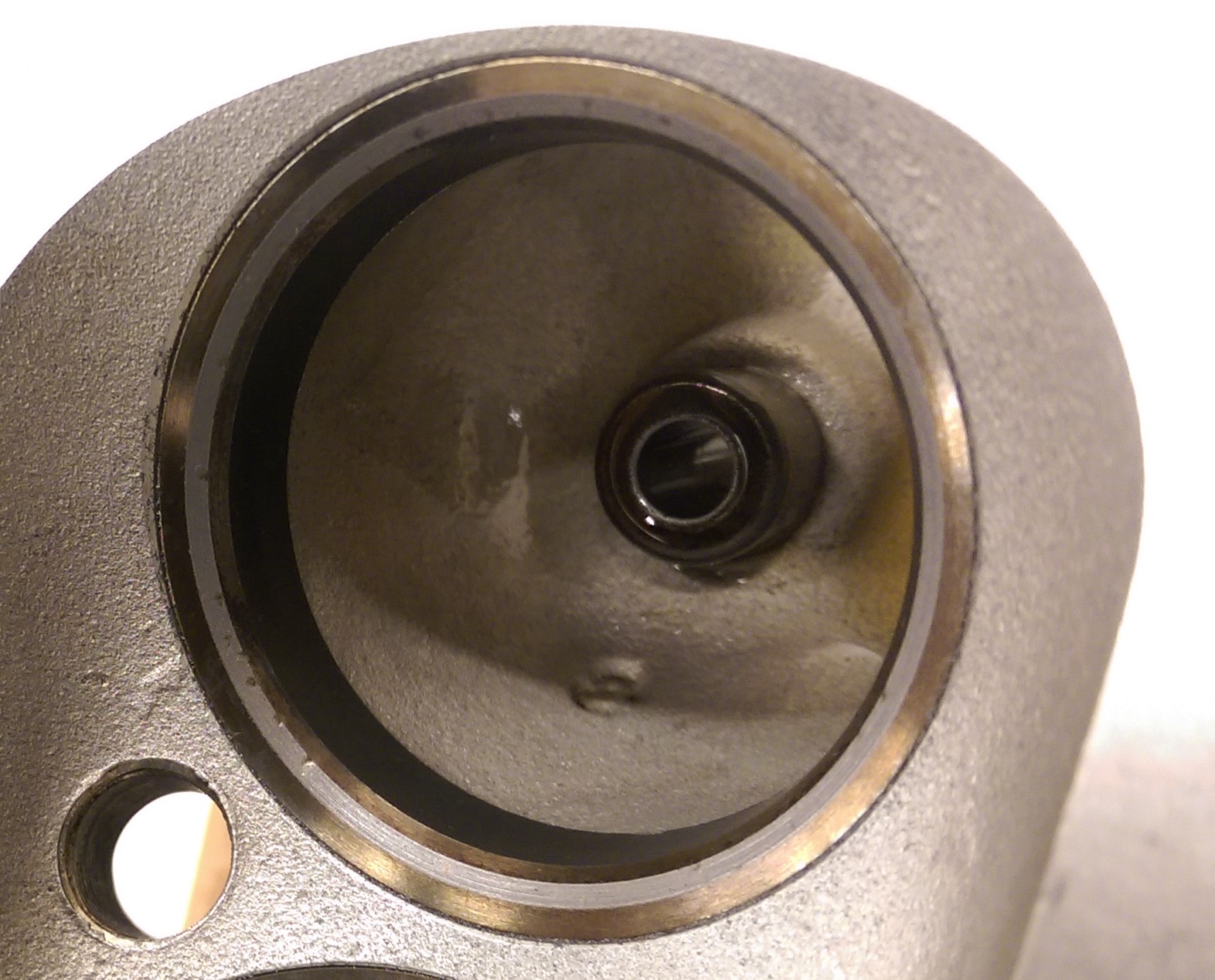

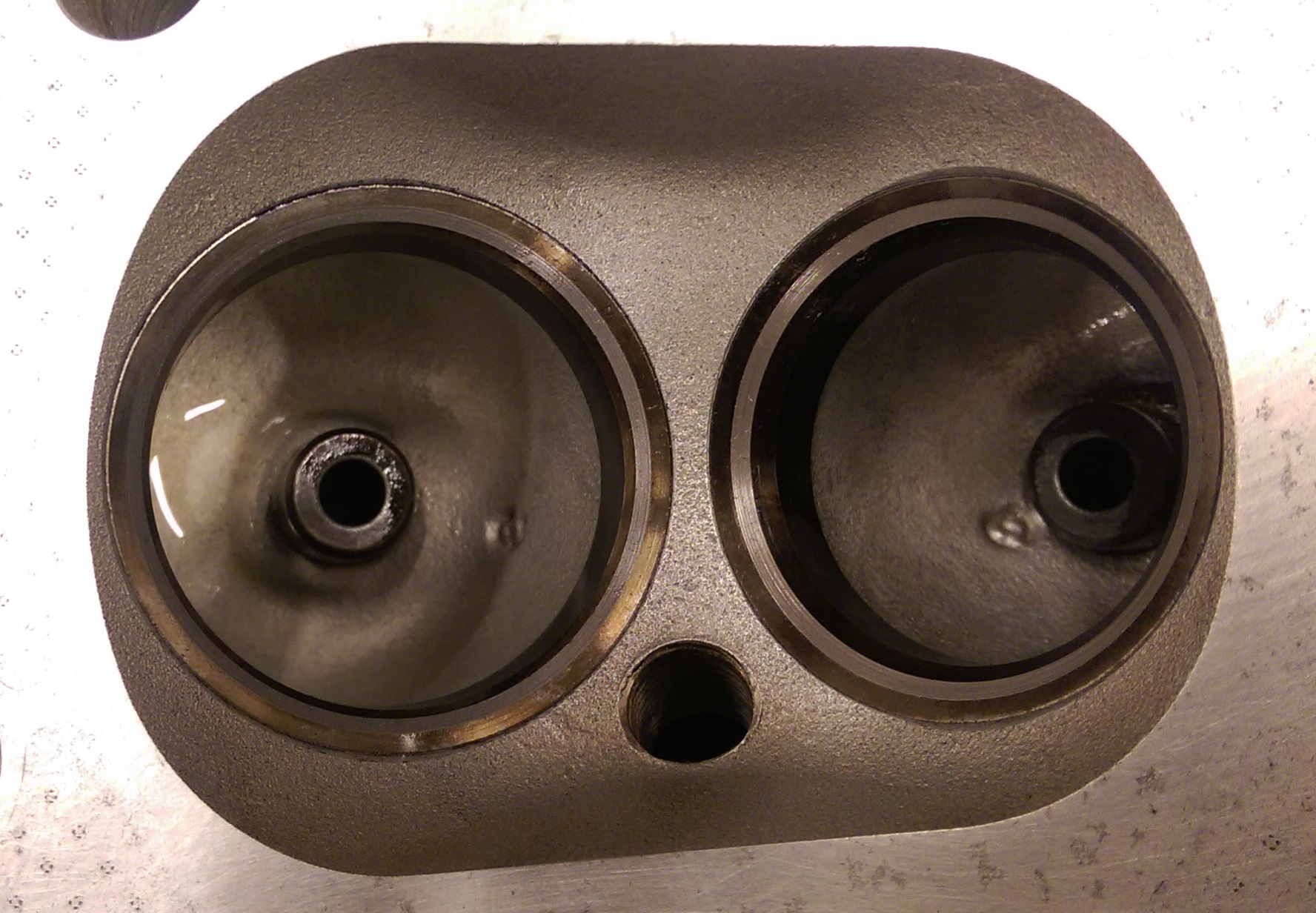

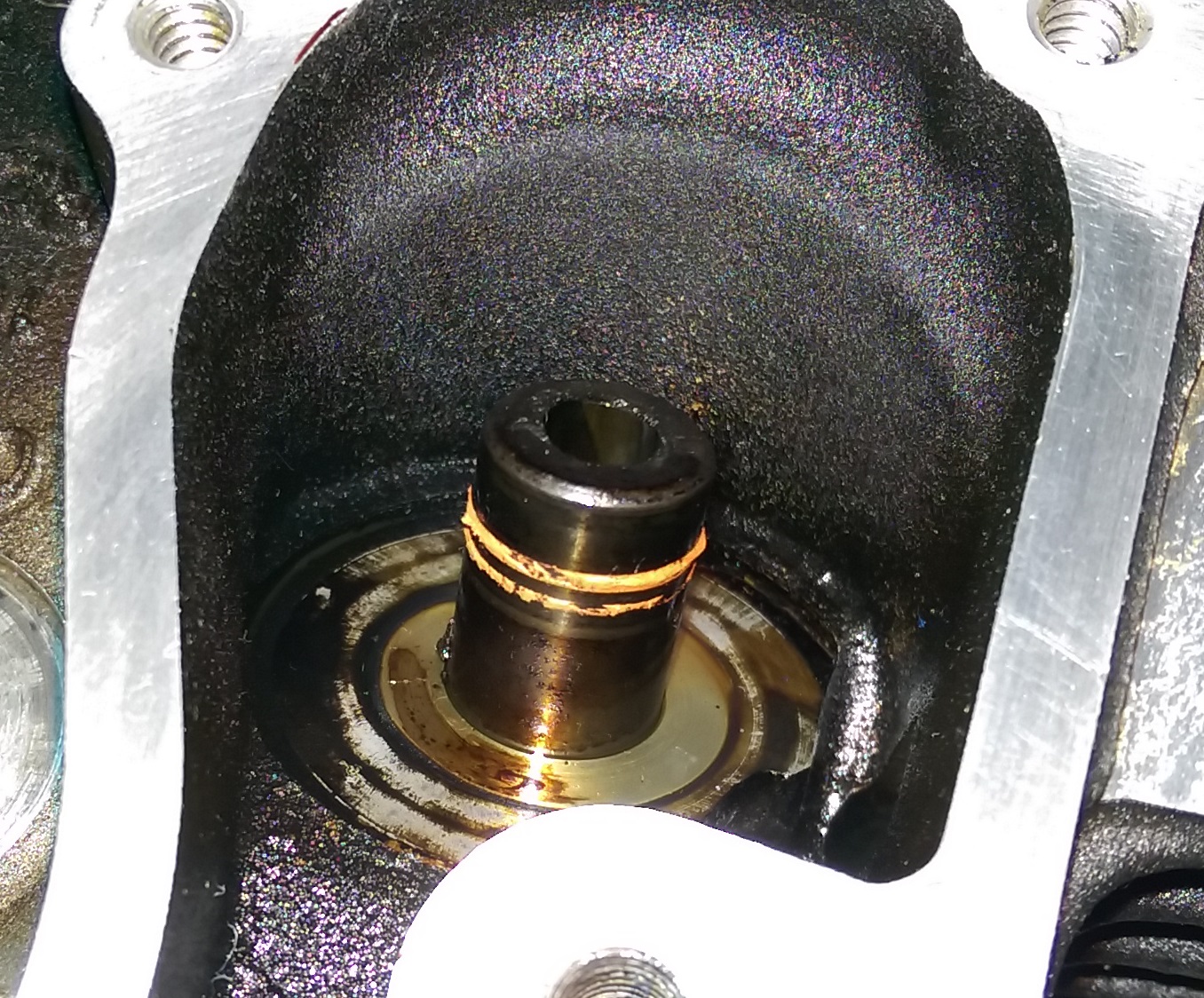

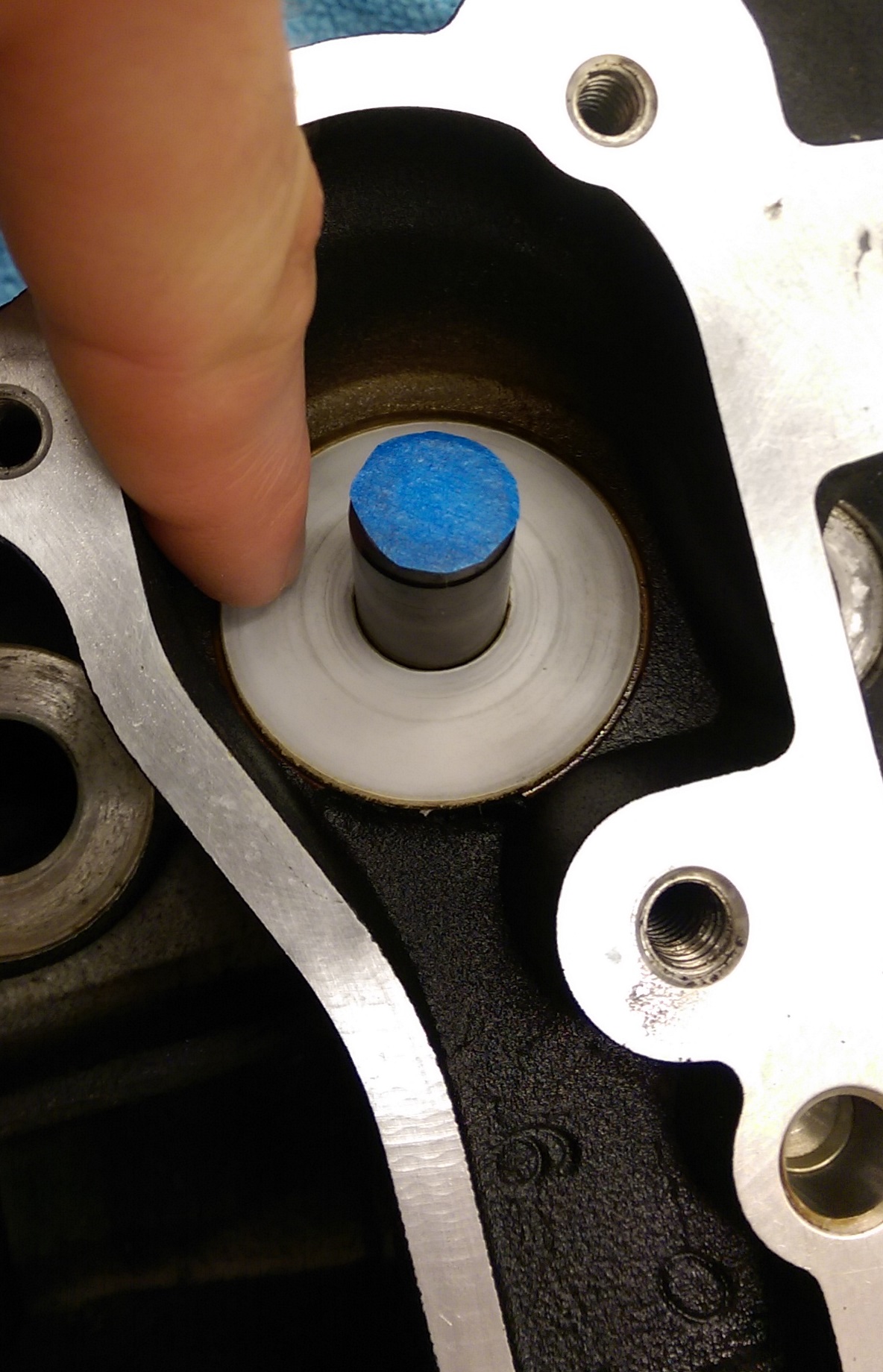

Here is exhaust valve seal after 20000 miles

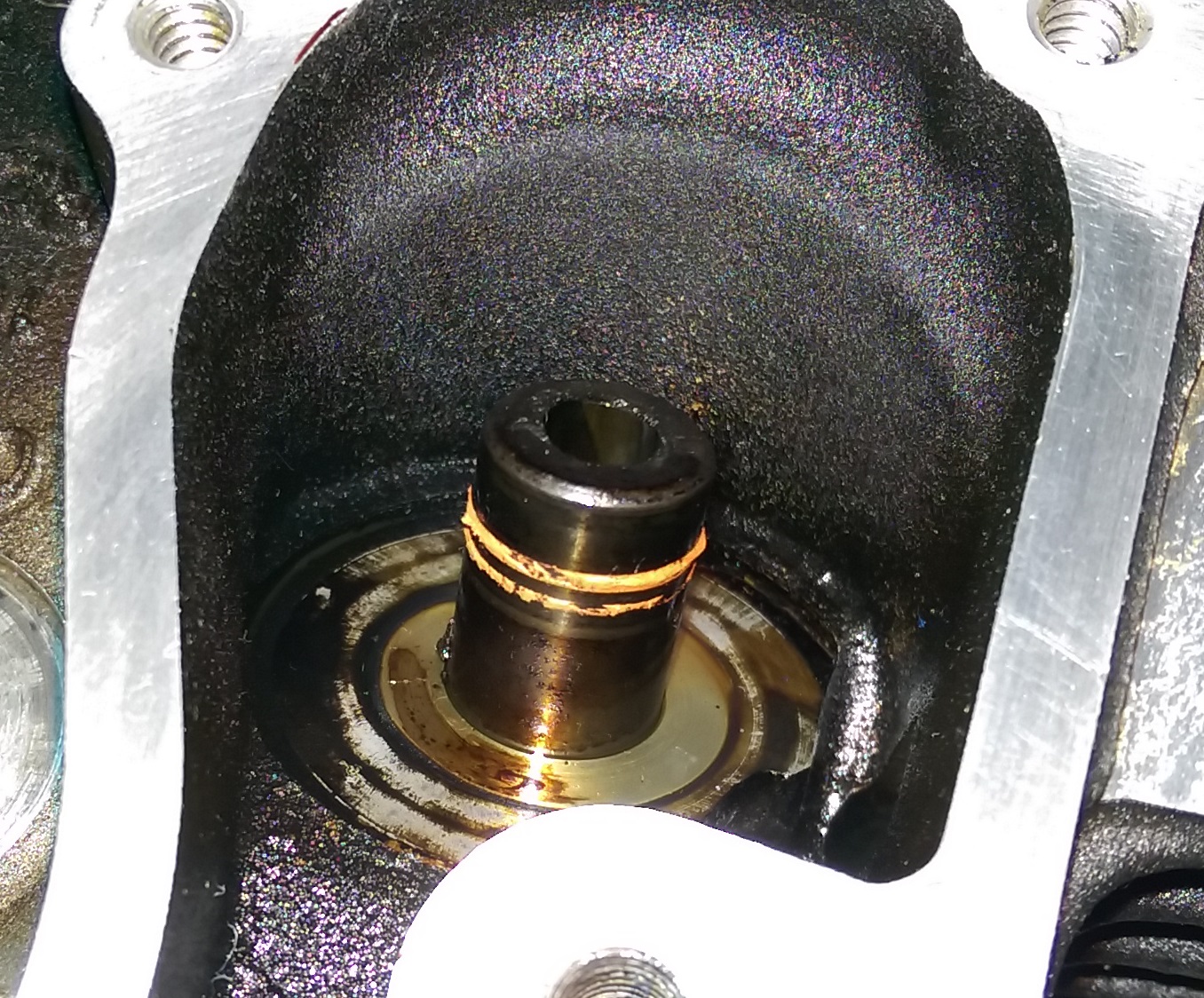

So after removing valves take pliers and carefully pull the metal part of the seal rocking and twisting it. It will likely came off without rubber part of the seal because of rubber deadly burned on the valve guide

Now take pliers and carefully massage the rubber all way around to brake rubber around valve guide. then take piece of wood or plastic tool and pry the rubber off. Do not use metal tool because you can scratch the valve guide.

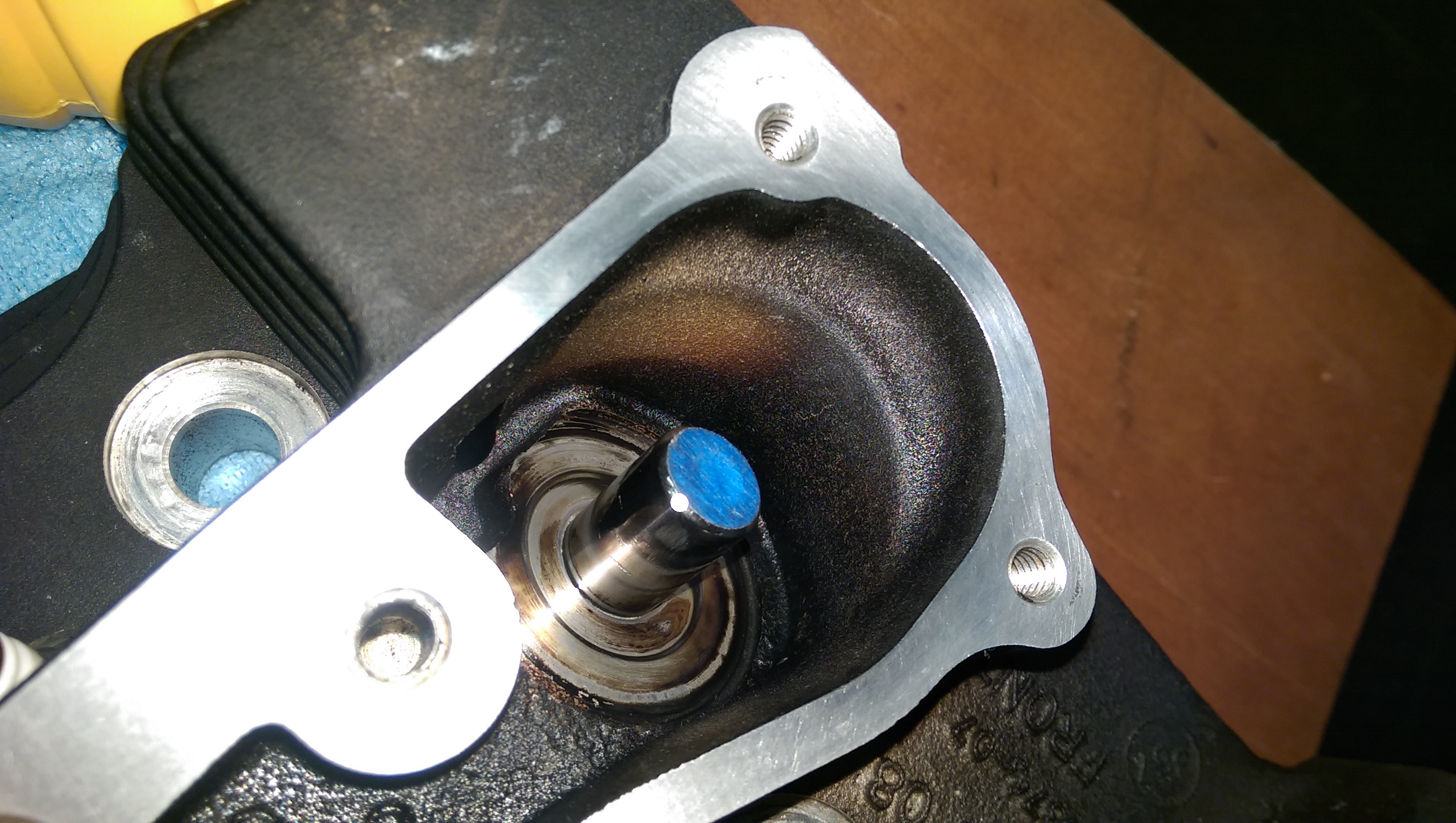

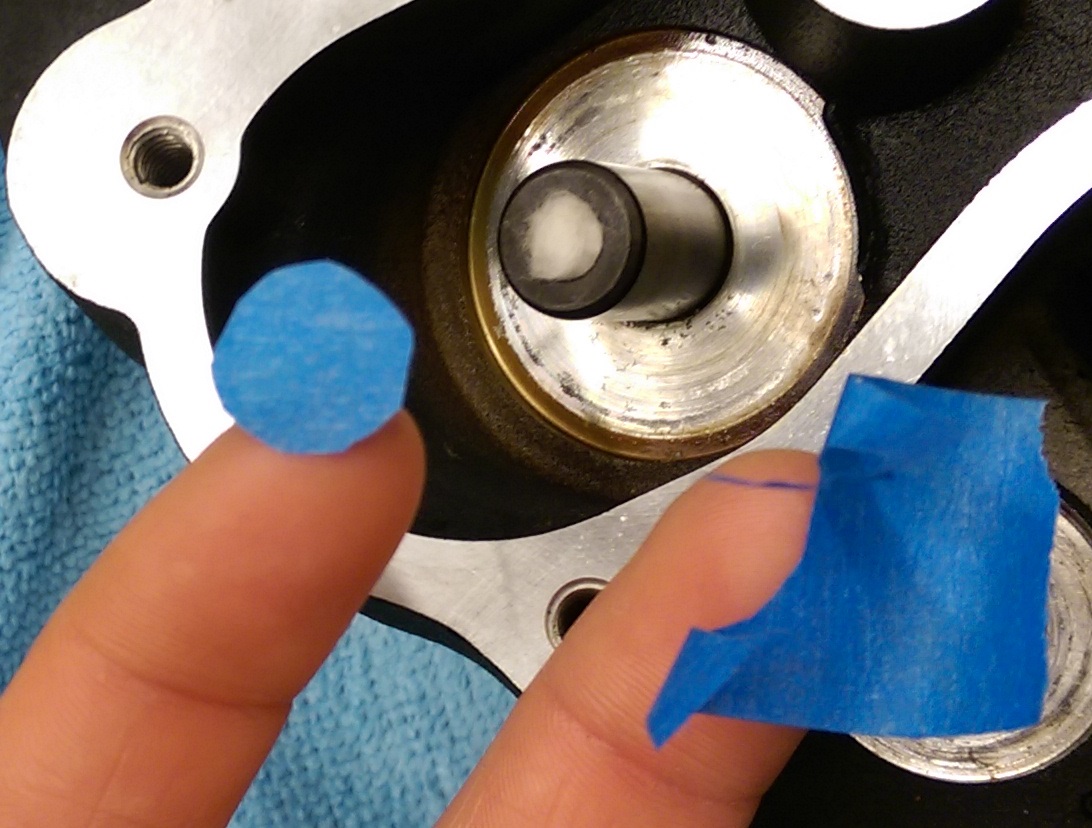

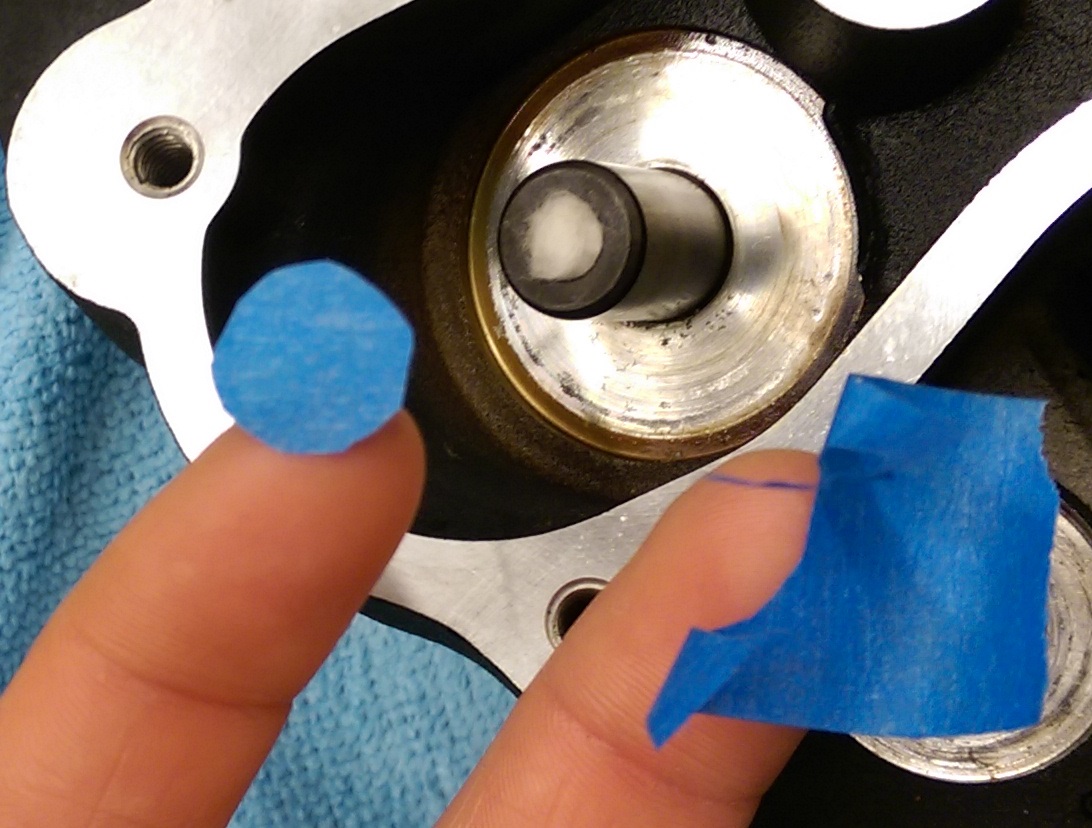

Protect the valve guide hole from abrasive material. I sticked piece of cotton and covered it by round piece of masking tape.

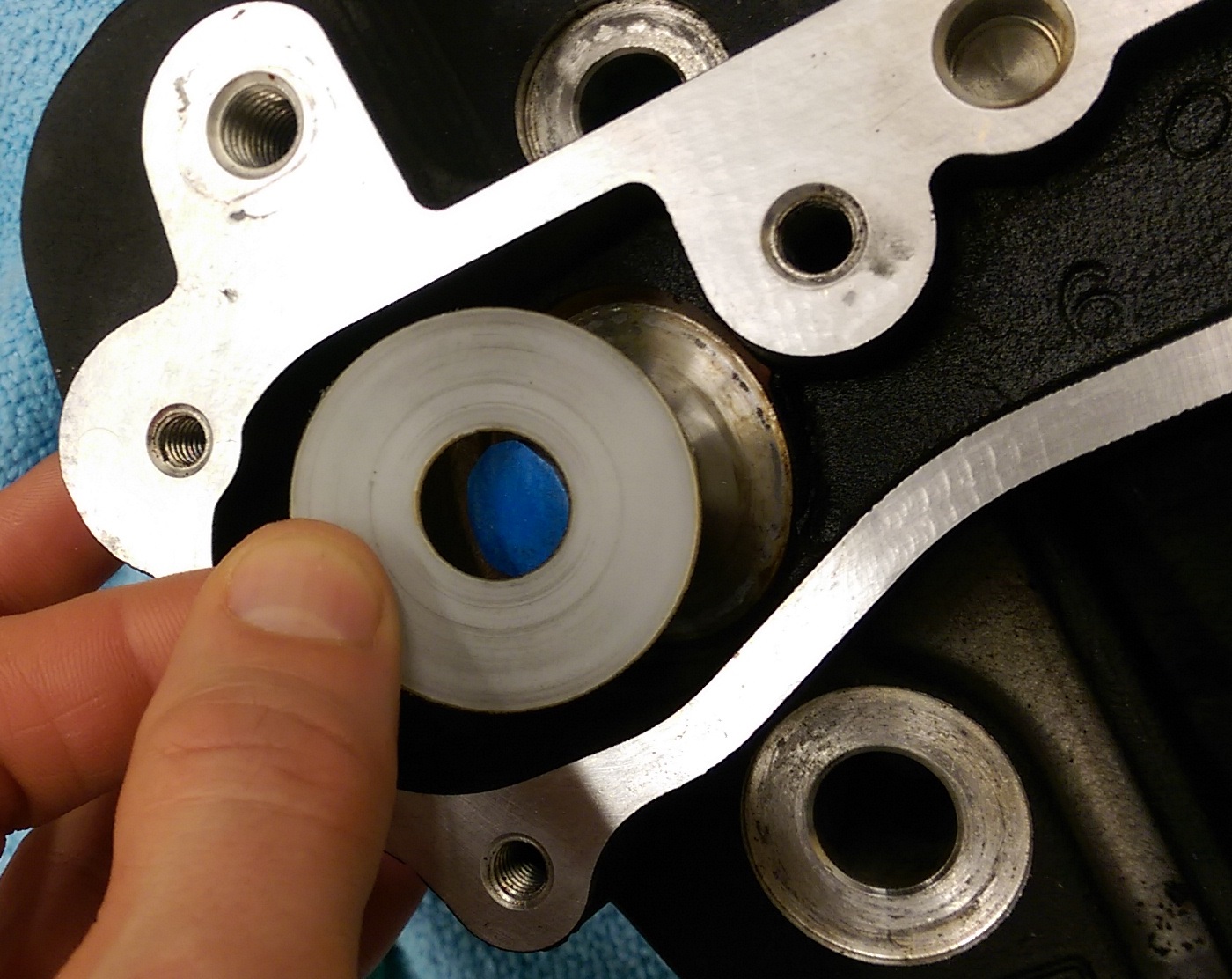

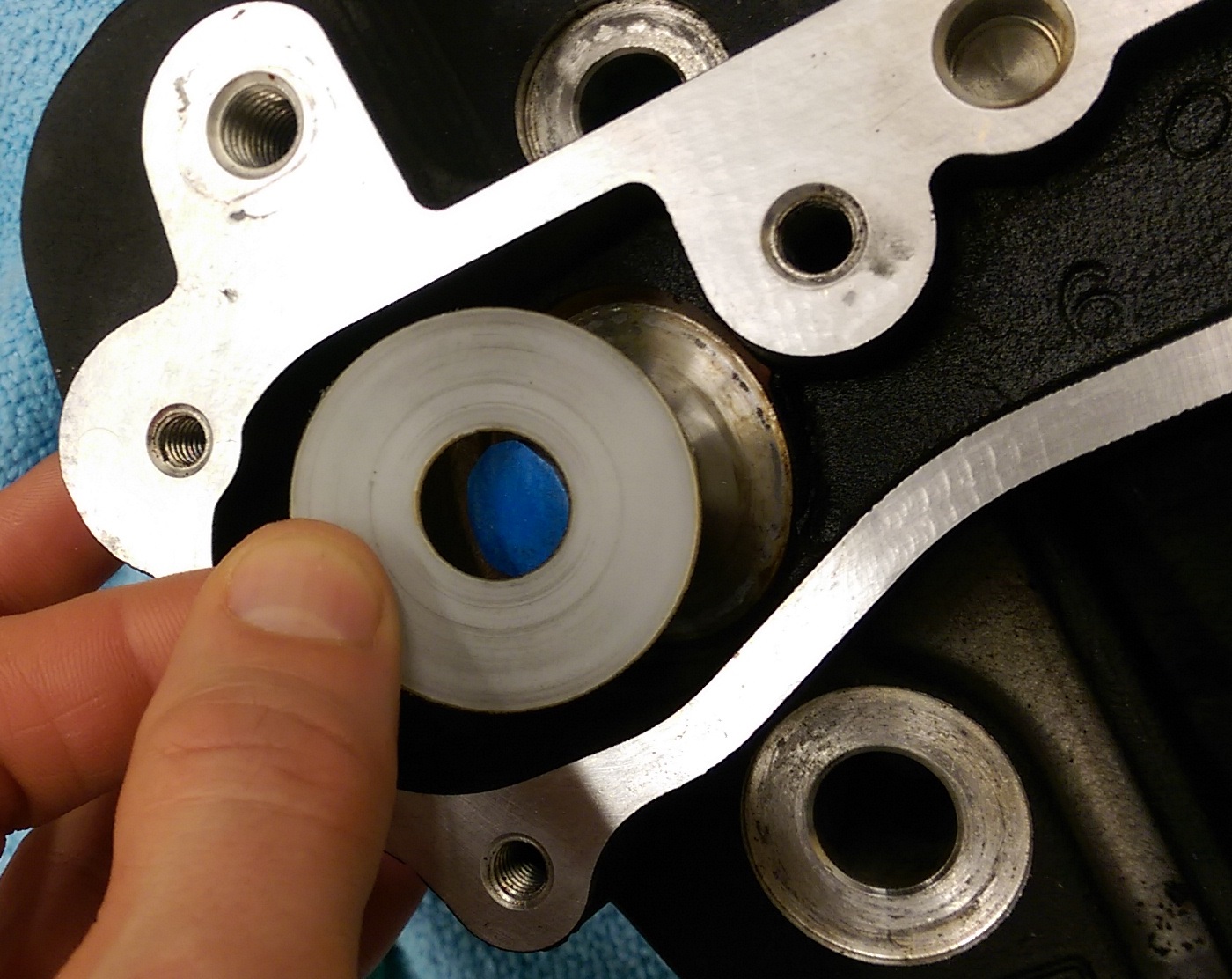

Cut round piece of plastic sheet of film to cover the gasket base surface and protect it from rubbing.

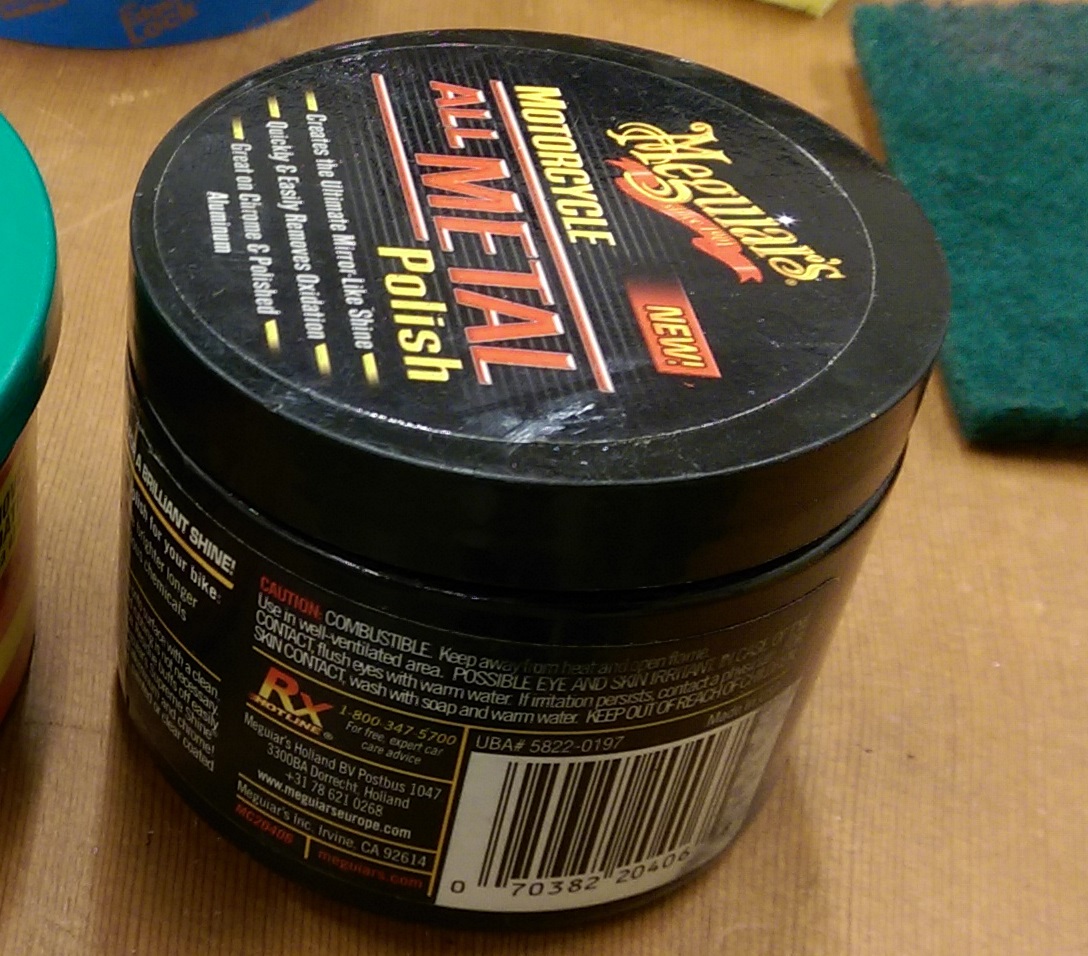

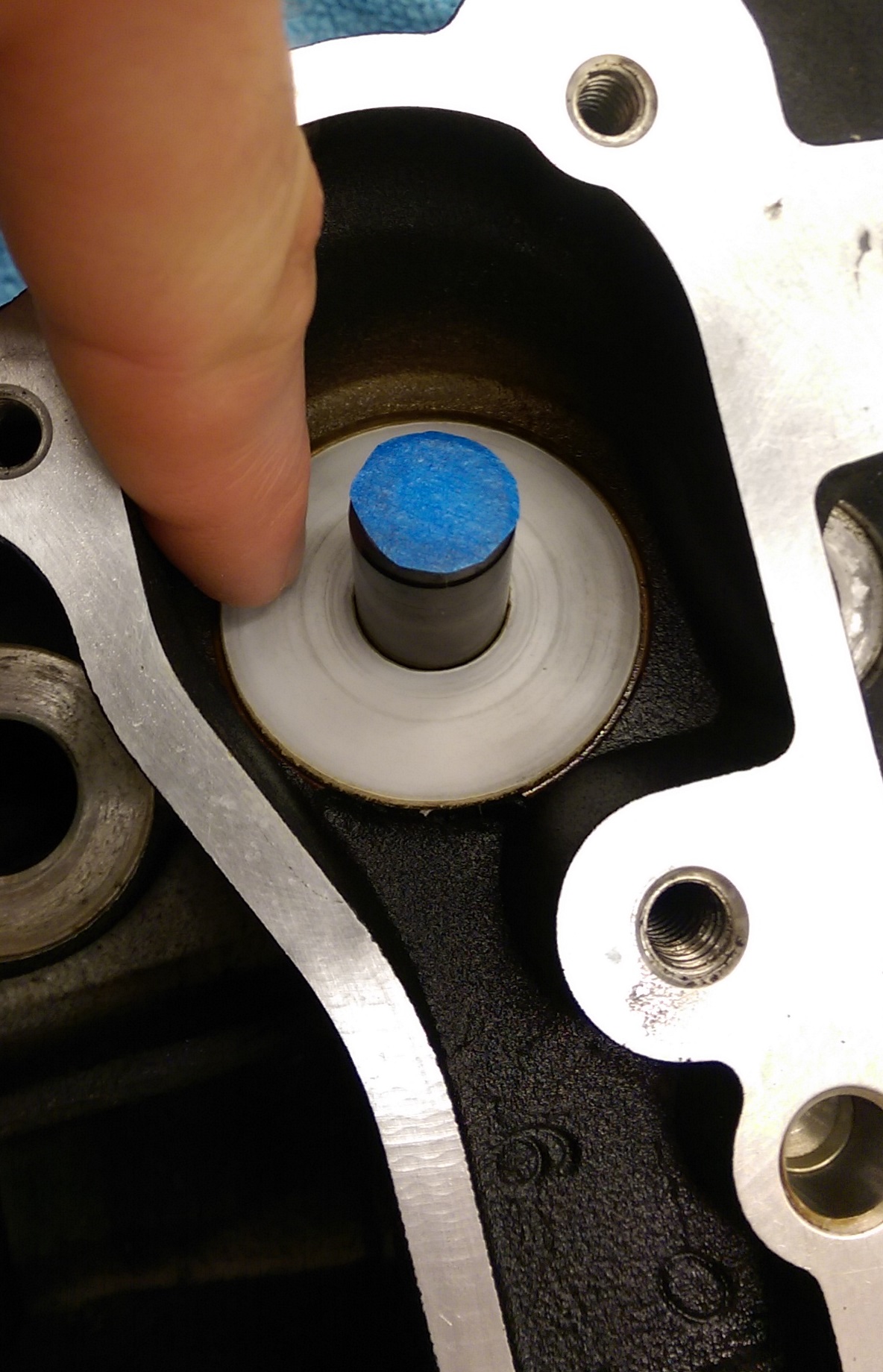

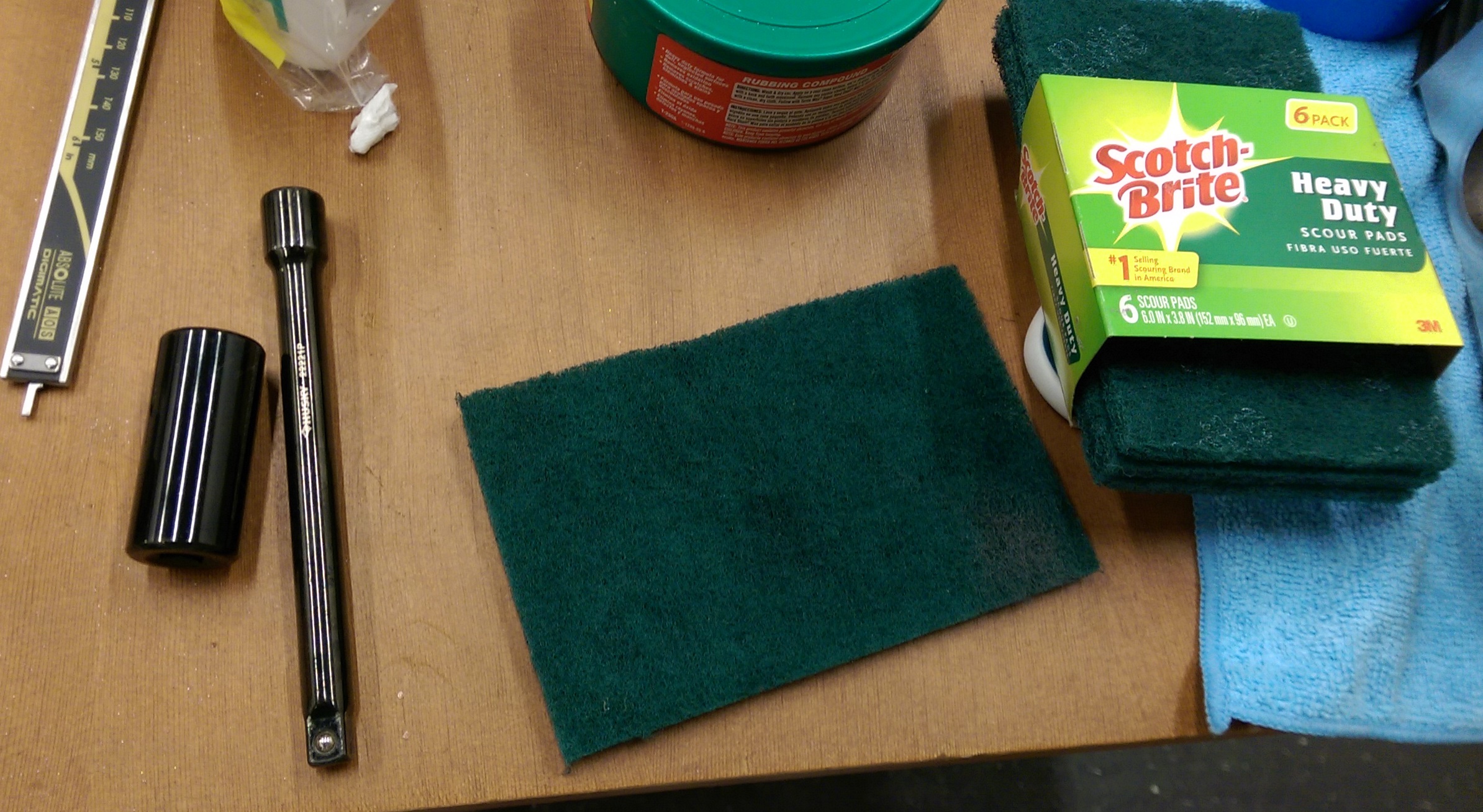

Take heavy duty Scotch-bright green pad, spray some WD40 on it and rub off the rest of the rubber from the valve guide manually.

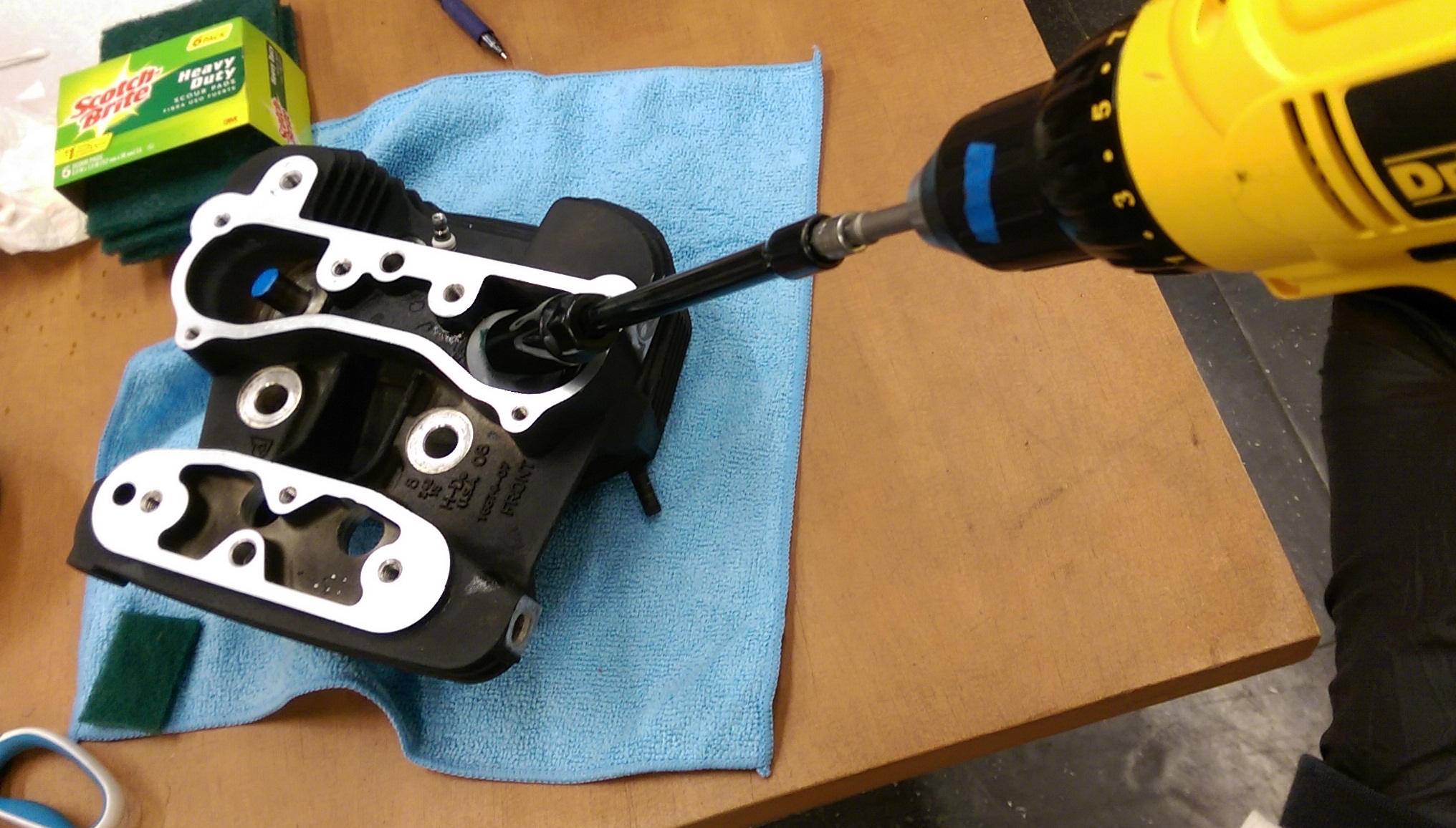

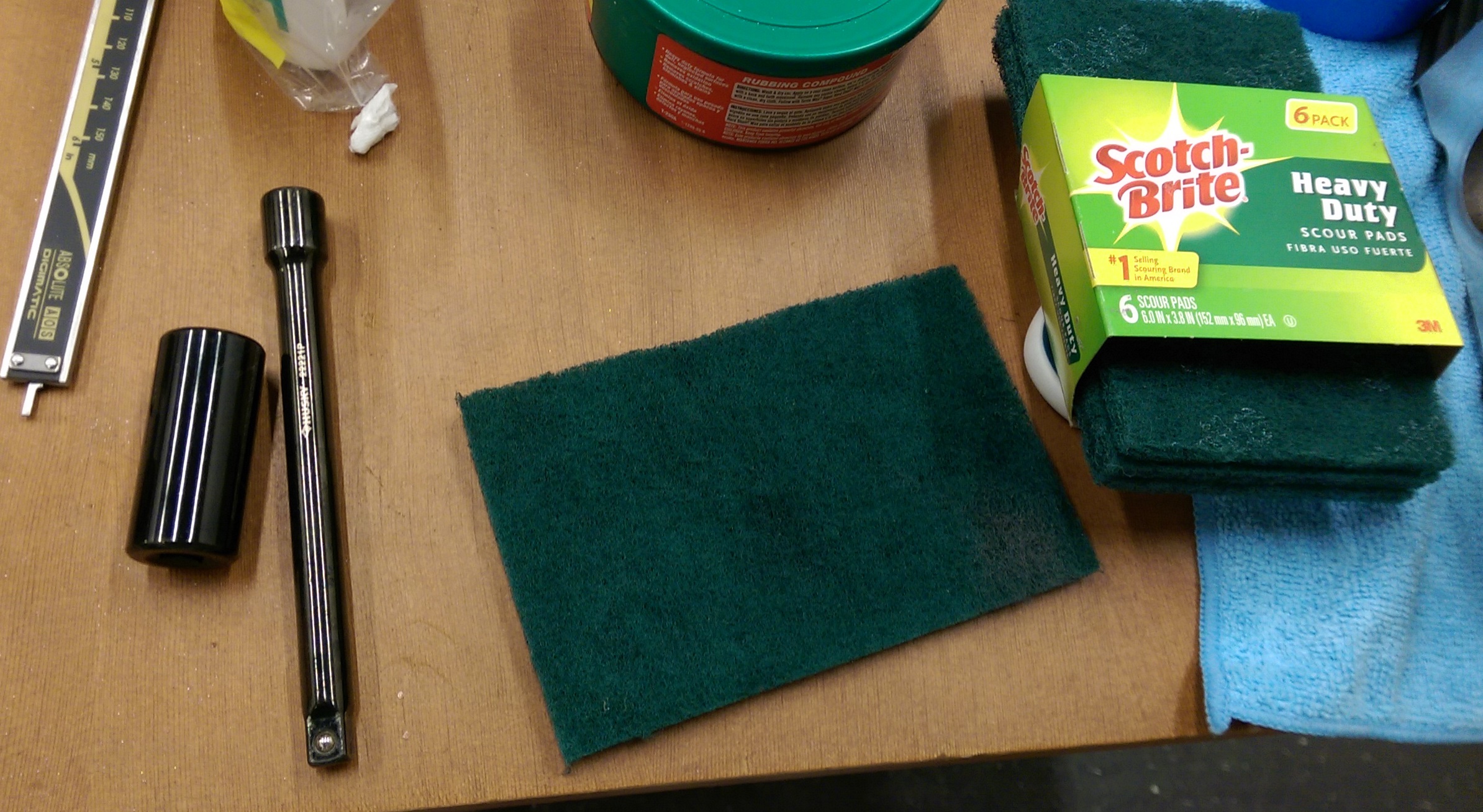

Now prepare 13/16 socket and extension for the socket

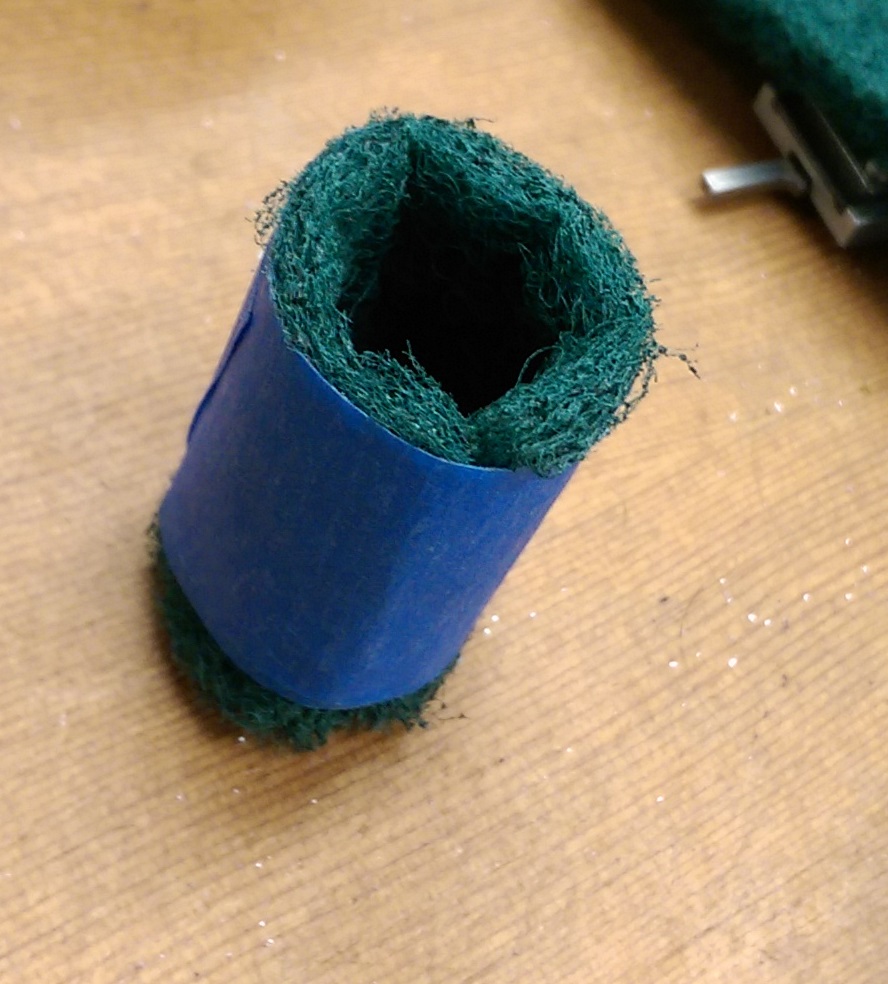

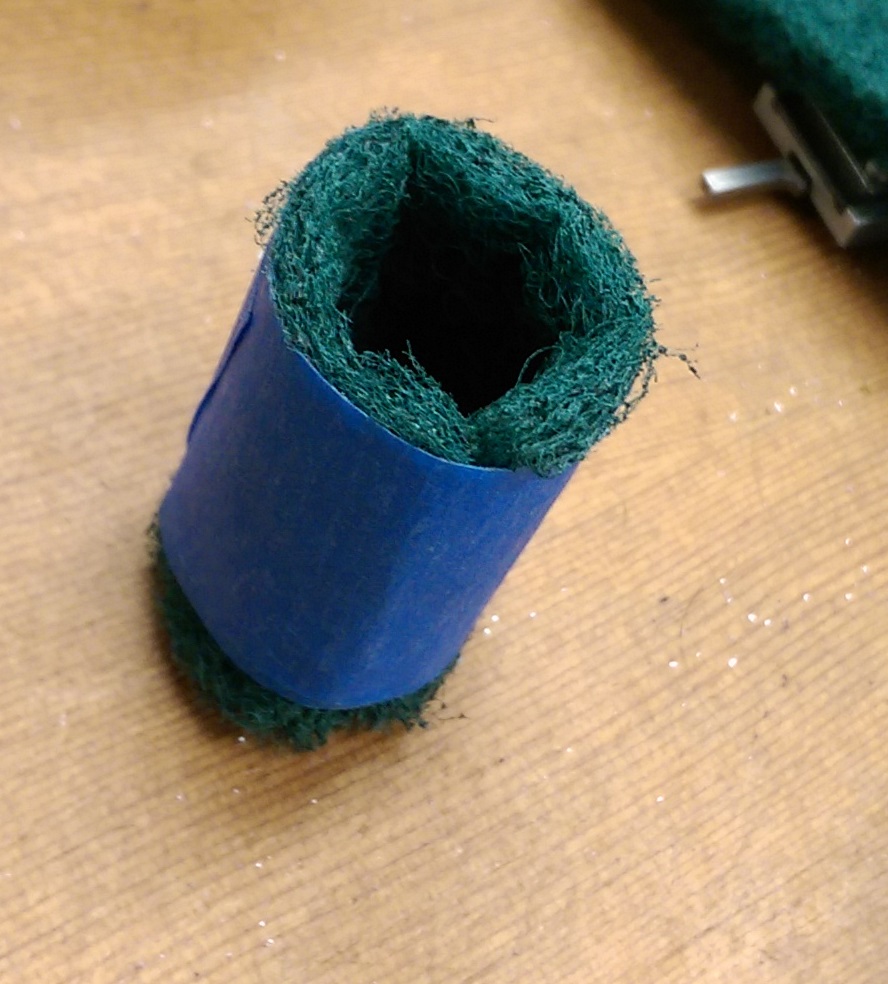

Cut piece of heavy duty Scotch-bright green pad so you can wrap the valve guide all way around

Wrap the pad with tape

Place the pad in the socket

Attach the socket with pad to the electric drill

Spray some WD40 on the pad and on the valve guide

If your motorcycle has many miles and you want to replace valve seals you probably will not be able to do this easily. The valve seal likely will be sticked on the valve guide with no any chance to be removed by bare hand with no tools even manual says opposite.

Here is exhaust valve seal after 20000 miles

So after removing valves take pliers and carefully pull the metal part of the seal rocking and twisting it. It will likely came off without rubber part of the seal because of rubber deadly burned on the valve guide

Now take pliers and carefully massage the rubber all way around to brake rubber around valve guide. then take piece of wood or plastic tool and pry the rubber off. Do not use metal tool because you can scratch the valve guide.

Protect the valve guide hole from abrasive material. I sticked piece of cotton and covered it by round piece of masking tape.

Cut round piece of plastic sheet of film to cover the gasket base surface and protect it from rubbing.

Take heavy duty Scotch-bright green pad, spray some WD40 on it and rub off the rest of the rubber from the valve guide manually.

Now prepare 13/16 socket and extension for the socket

Cut piece of heavy duty Scotch-bright green pad so you can wrap the valve guide all way around

Wrap the pad with tape

Place the pad in the socket

Attach the socket with pad to the electric drill

Spray some WD40 on the pad and on the valve guide

Last edited: