ok sorry guys, the thread kinda fell apart cuz the weather here went from freezing cold and ice racing to 70+ and i had to get it done cause i needed v-twin power instead of 250cc single cylinder power of you know what i mean

lol

anywhoo... ther 1250 kit is all the way broke in... break in was 400 miles according to NRHS performance, and just normal riding keeping it below 3700 RPM's... the first 150-200 miles i really went easy on accelerating too... but essentially i was just breaking in the rings, 90% of the valvetrain and cam and everything werent changes so no break in for them...

breakin oil i tried somethin new with this one cause i heard some good things about it from my old man in wisconsin that builds hot rods for a living... i used Royal Purple "engine break in oil" its basically a straight 30 weight NON-synthetic oil with certain detergents and stuff in it... the bike seemed to get a little warm on a warm afternoon and in slower traffic but with non synhetic and 30 weight its to be expected... i changed back to my normal Royal Purple 20W50 max cycle at 450 miles with no problems what so ever....

when finishing putting the kit togather everything went togather without a hitch except a few normal human error bobbles... like looking for the loctite bottle for a half hour and and putting the first circlip on the wrong side to push the wrist pin in, so had to slide a cylinder all the way off and re-start the piston lol but that was all my fault...

initial start up went very well... threw a brand new set of plugs on it just to make sure, went with a cheap set of champions just for start up in case i fouled out a pair... (it diddnt) but seeing as how much assembly lube NRHS tells you to use and how much i put in i was expecting it to foul out...

popped right off on about the 3rd reveloution of the crank, no porblems let it heat up for a little bit and then shit it off after no rattles or anything...

then had to hook up ecm spy and figure out all my map stuff for fuel and timing advance... i started with a basic map, and since m displacement went up by 15% i highlighted my entire fuel map in ecm spy and timesed it by 15% for the front cylinder and 17% for the rear cause the rear needs a little more for cooling... for timing advancement NRHS reccomended 5 degrees but from conversations with mike cobb (xopti) i actually went 7 degrees.... after datalogging and puttin a few miles on the bike with this map my air fuel value was PERFECT so i diddnt change anything till dyno tuning wich actually diddnt make me change much....

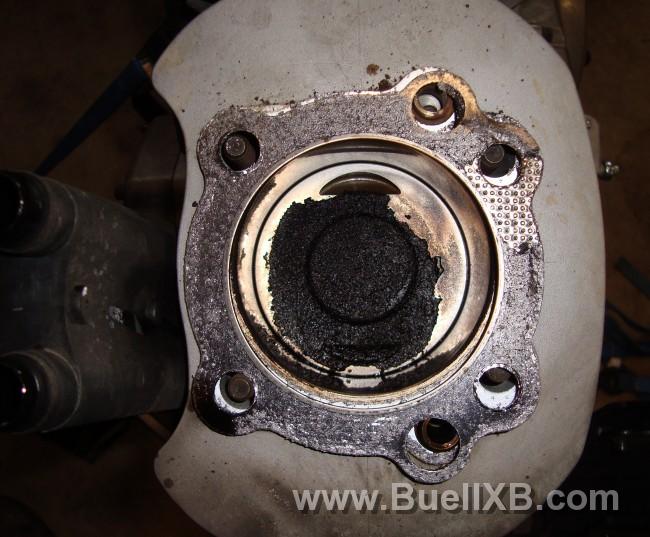

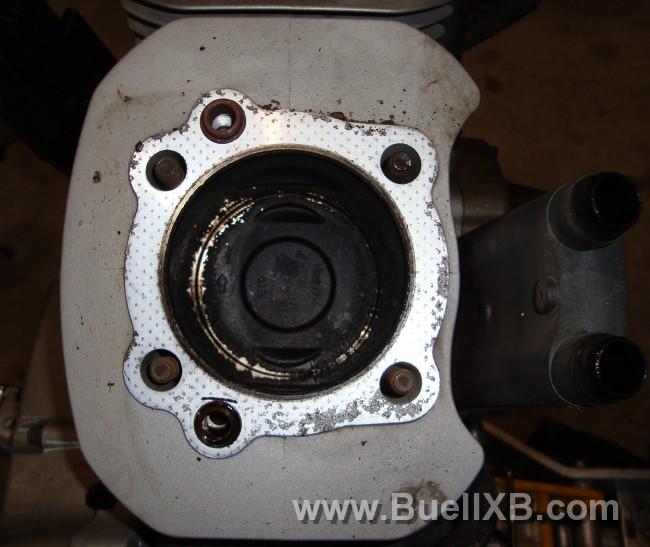

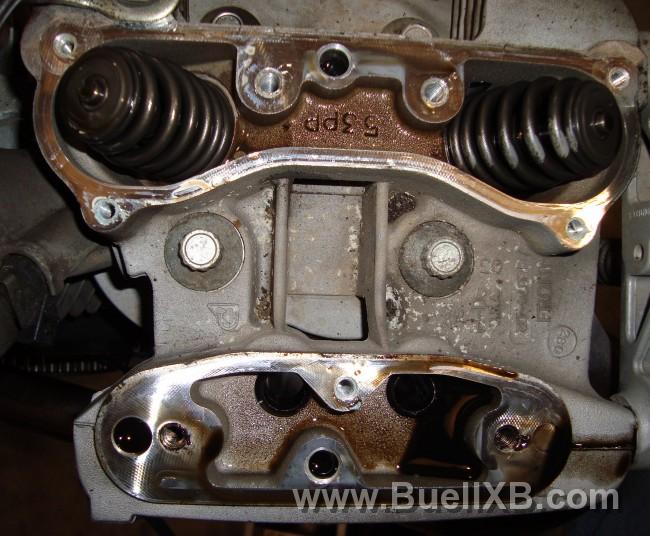

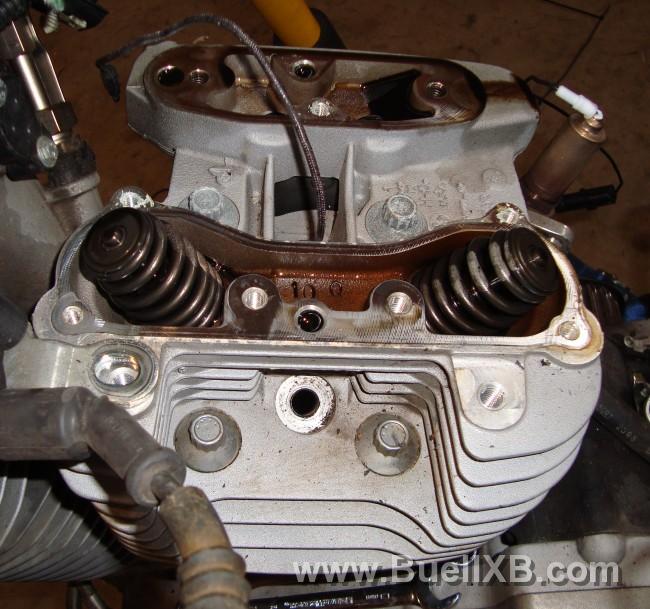

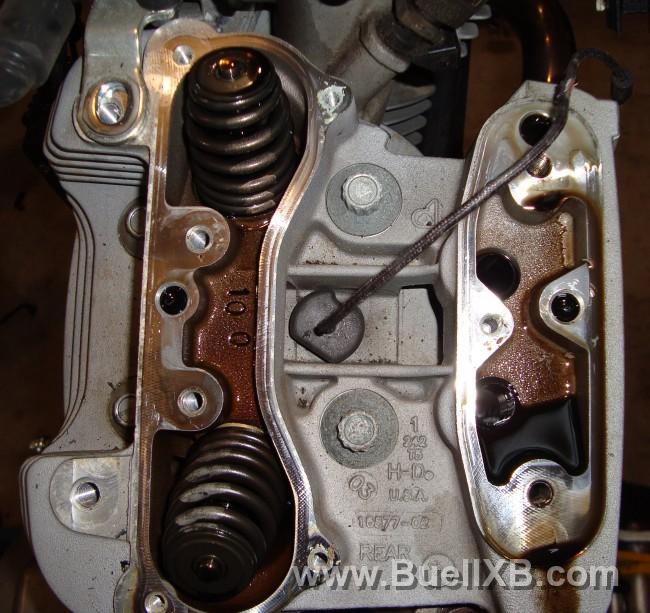

but after about 22 miles on the bike a noticed some oul leaking down the front push-rod tube... so i decided to just rotate down the motor and pop a head and take a peek, the front pushrod o-ring between the tube and the cylinderhead has actuall seperated (2 peice o-ring) so i decided i wasnt going to let the back ones slide even though they werent leaking... so i dropped the motor and poped the back head and they werent far behind... i later found out m problem... the gasket set i had was all brand new and sealed in the box, but i got it from a clearance table at an HD dealership for like $40... that was a screaming deal but i never looked and the dates on the box, the gasket set was made in 2003 and the o-rings must have dry rotted and started seperating... so threw a brand new set of genuine james o-rings in here and have been good to go ever since (now at 1748 miles since re-build)

i know this was super long already but it in no way covered everything i did by an means... if anyone wants to know what i used for gaskets-silicones-spectialty tools or any of that just let me know and ill post up...

i also did alot of work claying my heads and checking squich clearance's and stuff to if anyone wants to get into all that jazz... its alot of work but you will make alot more power out of your money your stuffing into your bike...

casey