Today I'm going to show you how you can install 50$ steering damper setup on your Buell XB instead of spending 500$ for a ready kit.

Firs of all a little sneak peek.

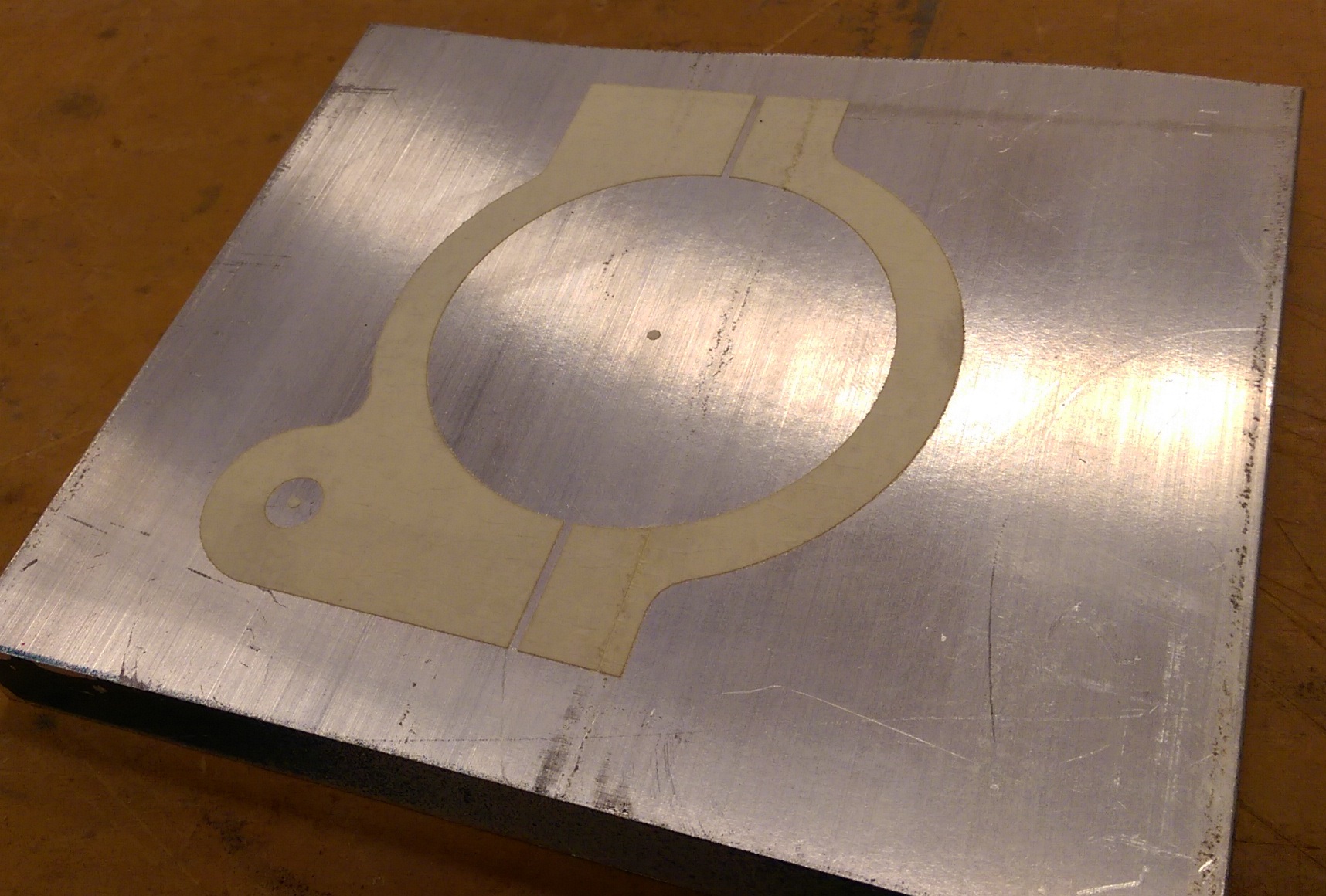

My CAD model to check fitments of the steering damper components

Installed damper

Alright. Here is list of parts you will need:

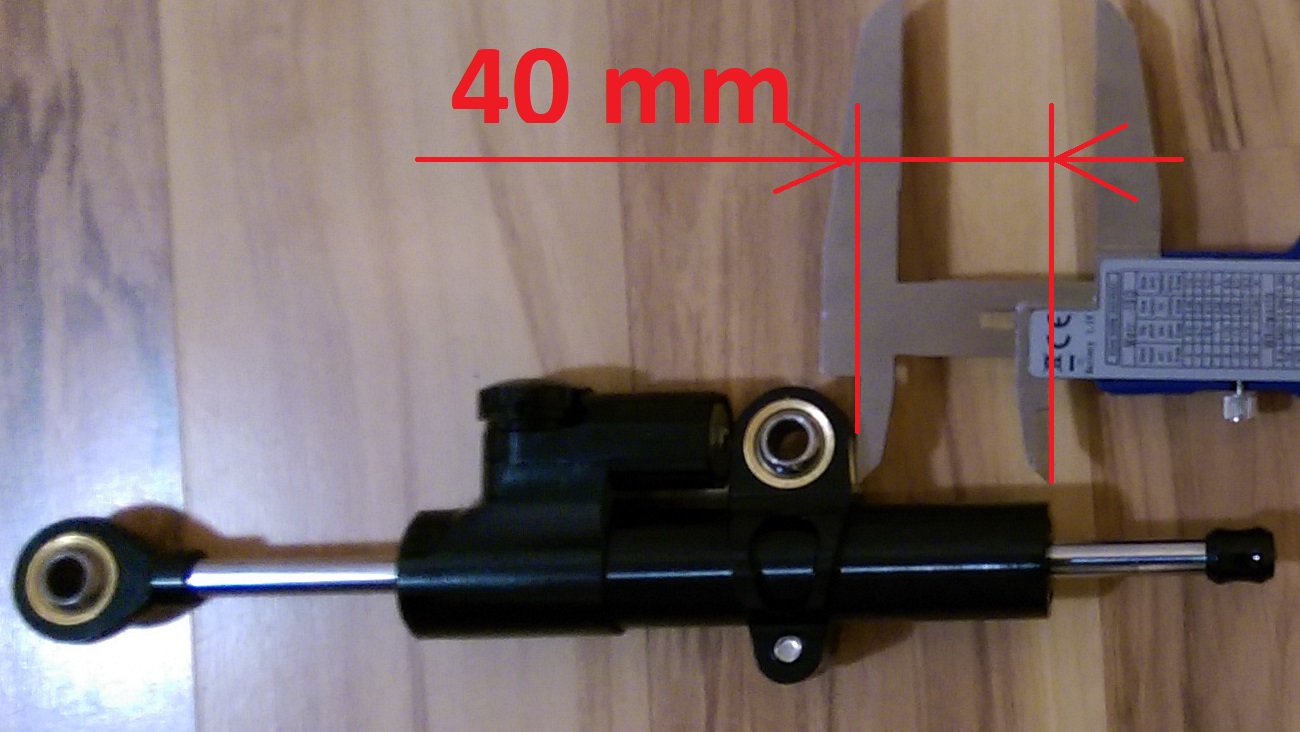

- Steering damper itself, no additional brackets, just $35 damper (you can pick any color you want) https://www.amazon.com/gp/product/B01FMOJ1TO/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

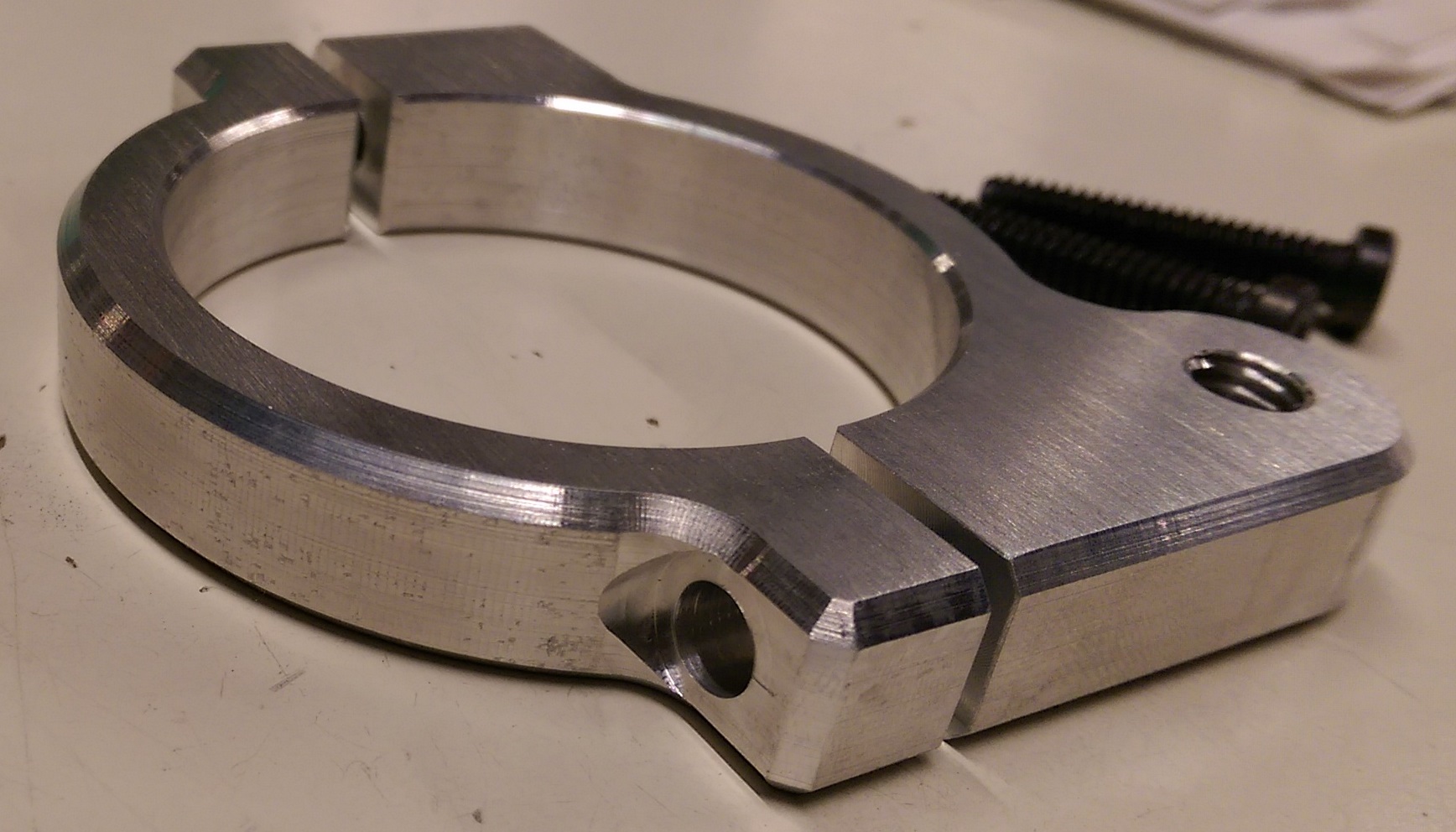

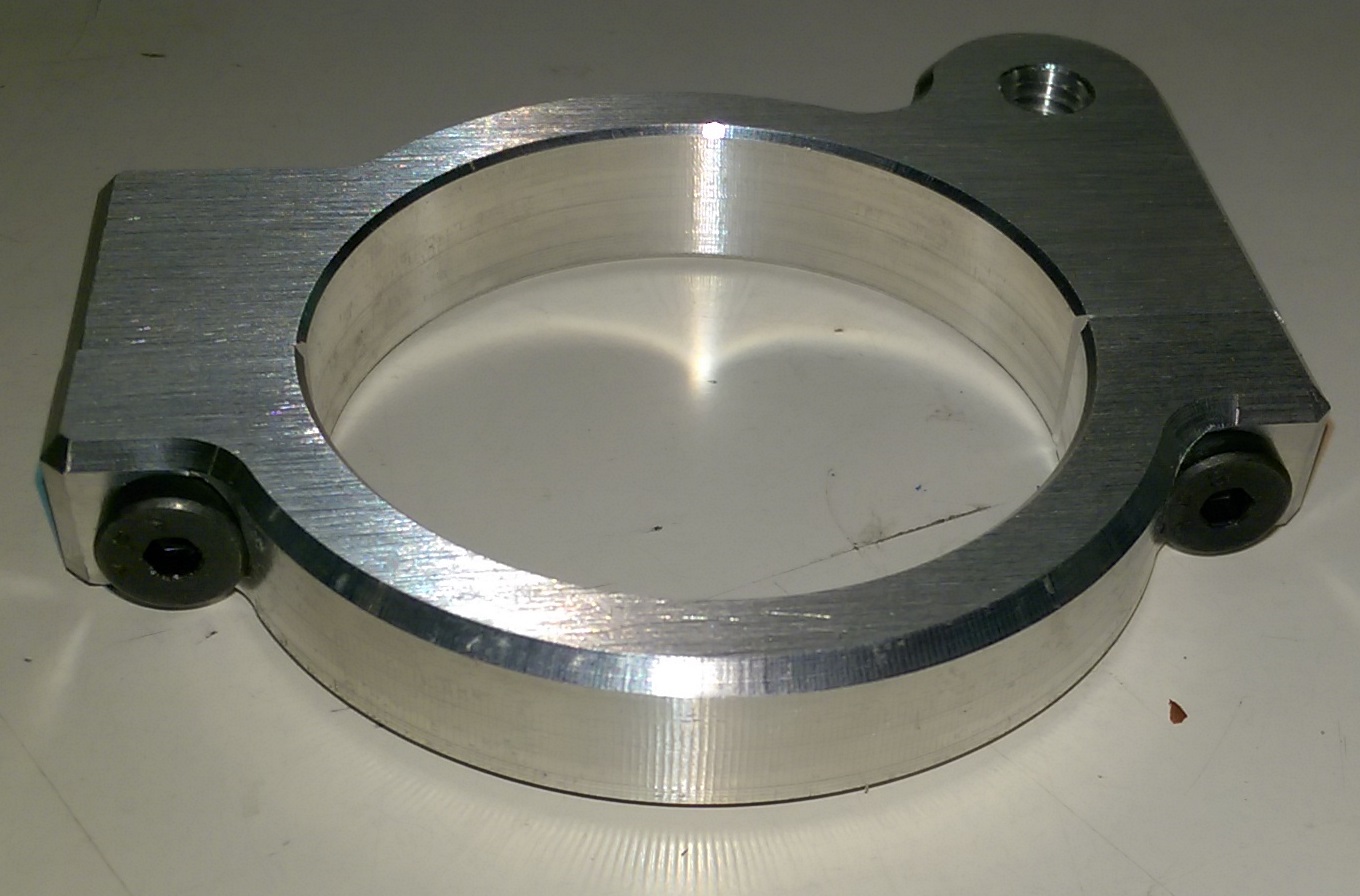

- 54 mm diameter steering damper fork clamp (for 2009 Buell XB12Scg diameter is 54 mm, if you have another year motorcycle verify you fork diameter where you are going to attach bracket, if it is different you have to buy bracket with diameter you need) https://www.amazon.com/gp/product/B01N2ZTDL8/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

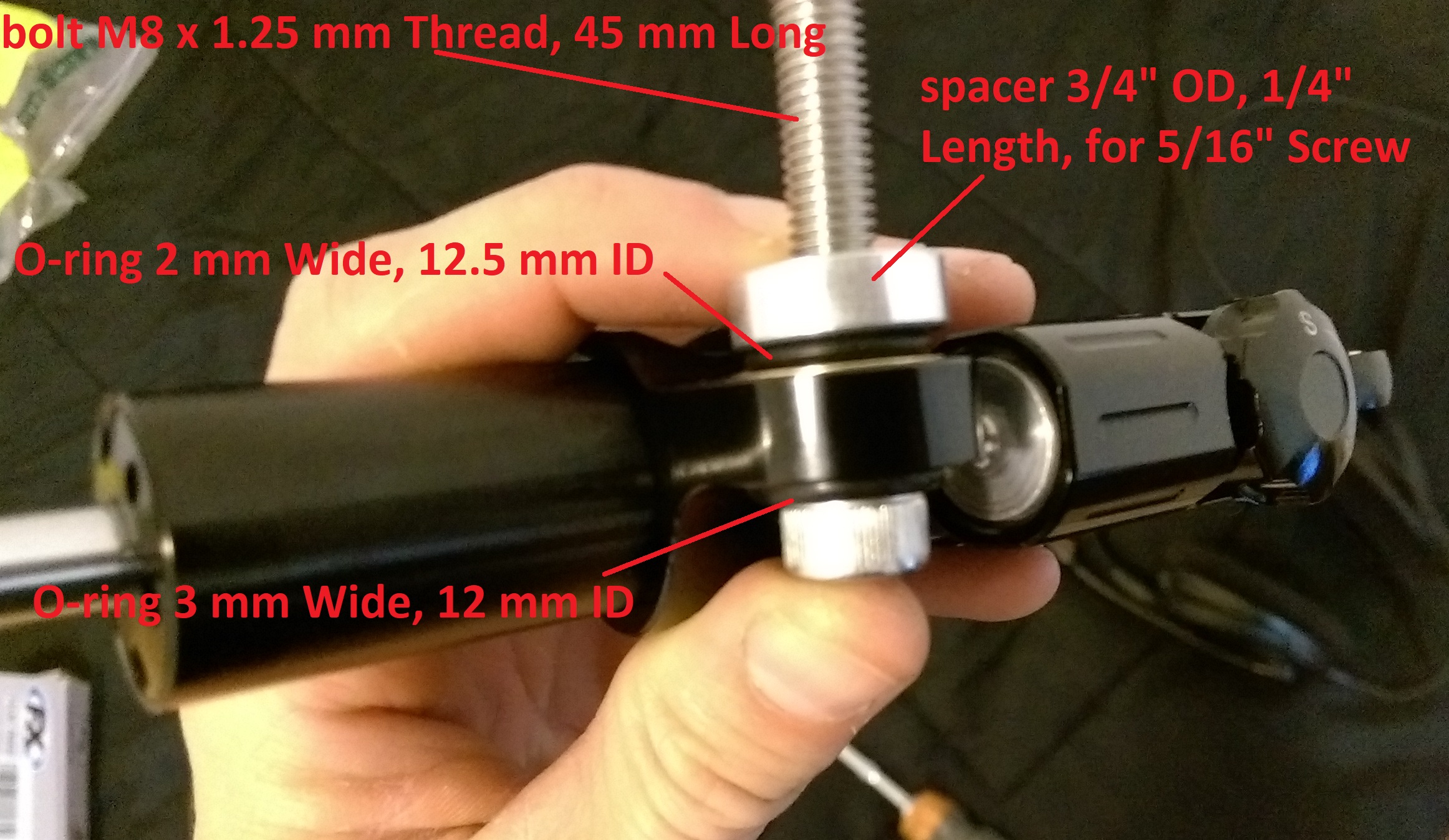

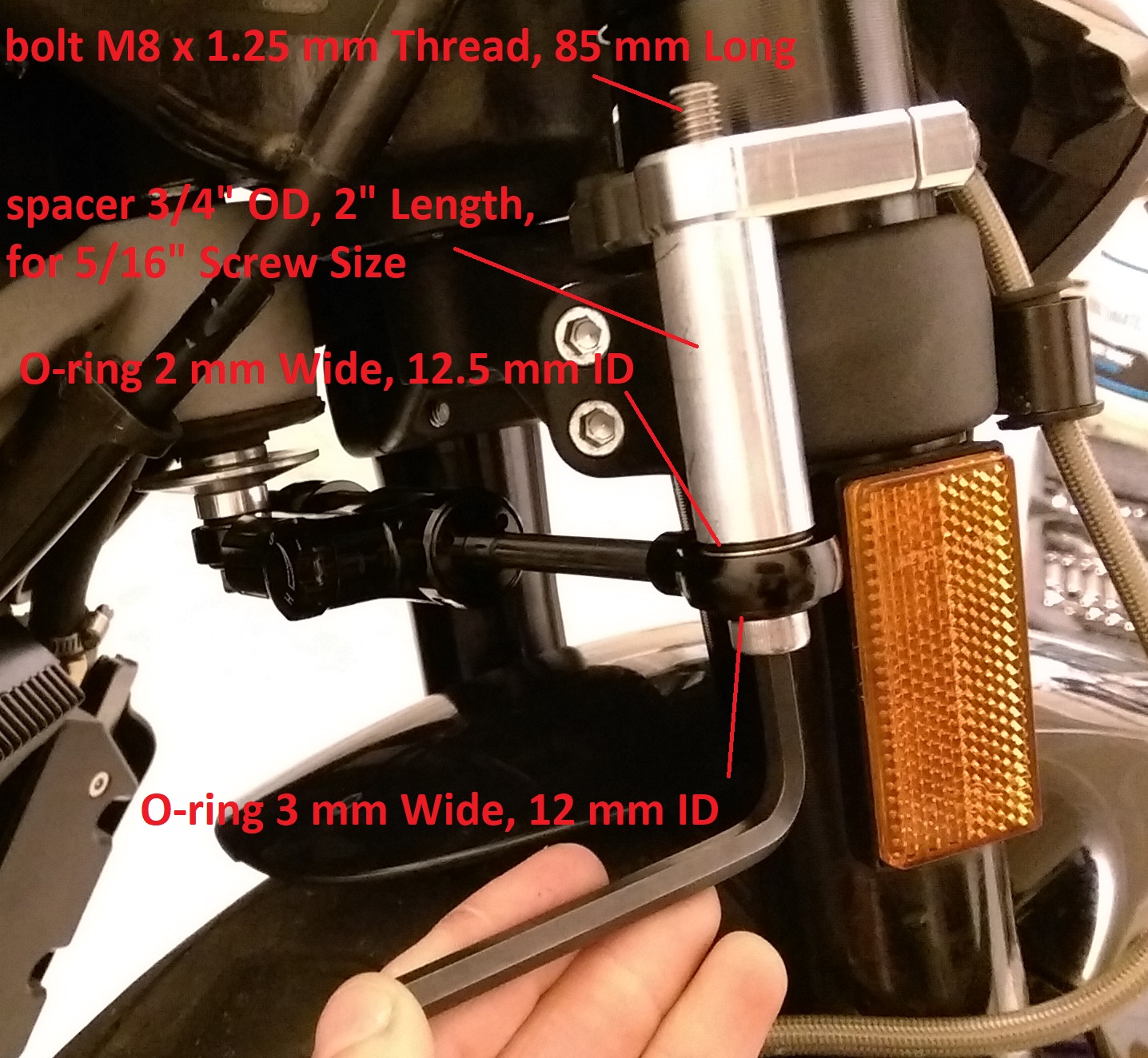

- 2 O-rings 3 mm Wide, 12 mm ID https://www.mcmaster.com/#9262k266/=19kpraa

- 2 O-rings 2 mm Wide, 12.5 mm ID https://www.mcmaster.com/#9262k852/=19kprbs

- One bolt M8 x 1.25 mm Thread, 45 mm Long https://www.mcmaster.com/#92290a446/=19kprbl

- One bolt M8 x 1.25 mm Thread, 85 mm Long https://www.mcmaster.com/#92290a462/=19kprc4

- One spacer 3/4" OD, 1/4" Length, for 5/16" Screw Size https://www.mcmaster.com/#92510a489/=19kprdg

- One spacer 3/4" OD, 2" Length, for 5/16" Screw Size https://www.mcmaster.com/#92510a813/=19kpre0

- One nut M8 x 1.25 mm Thread with nilon insert https://www.mcmaster.com/#94710a104/=19kprdm

Now you can start build you own steering damper kit.

First of all remove front isolator bolt bolt from your motorcycle.

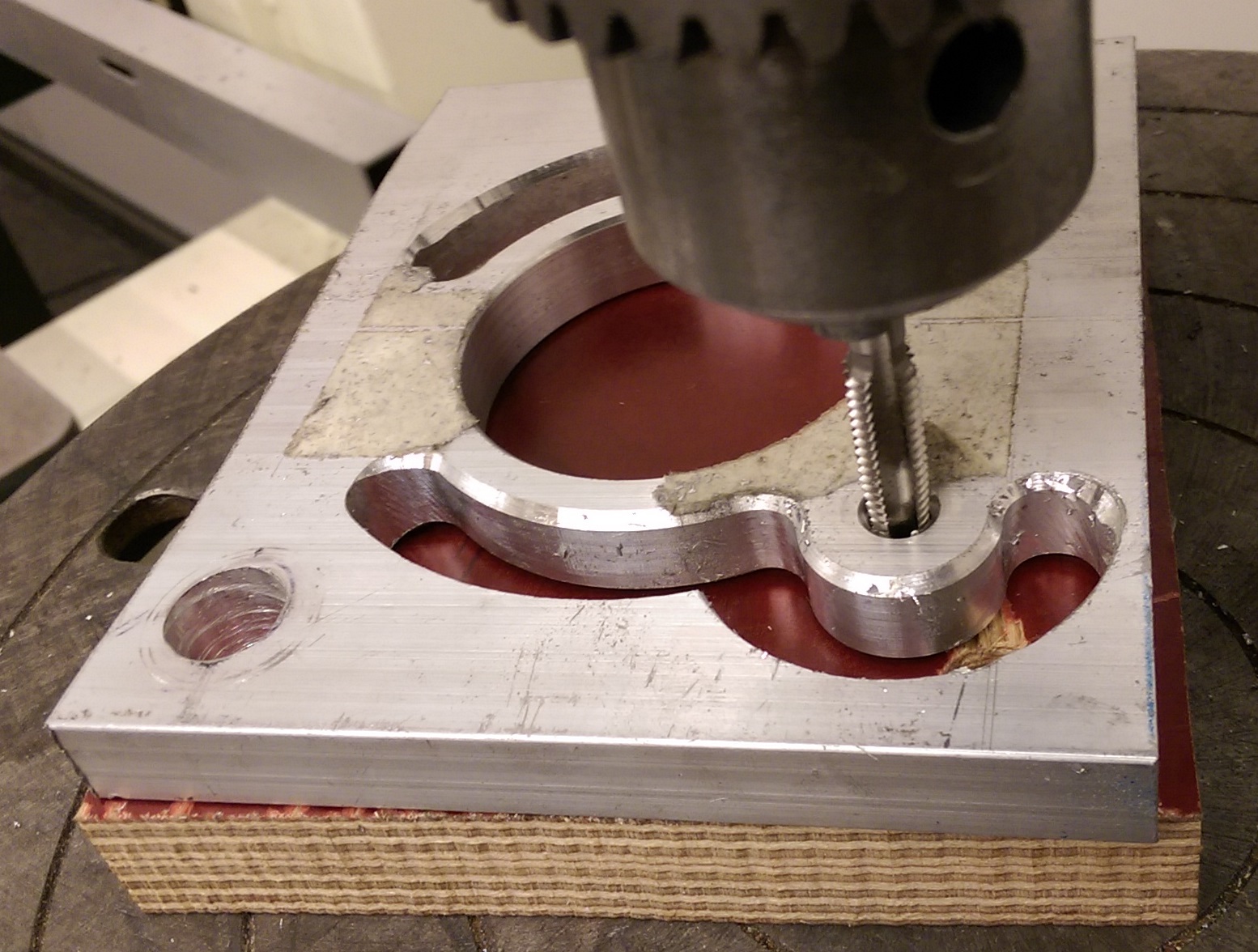

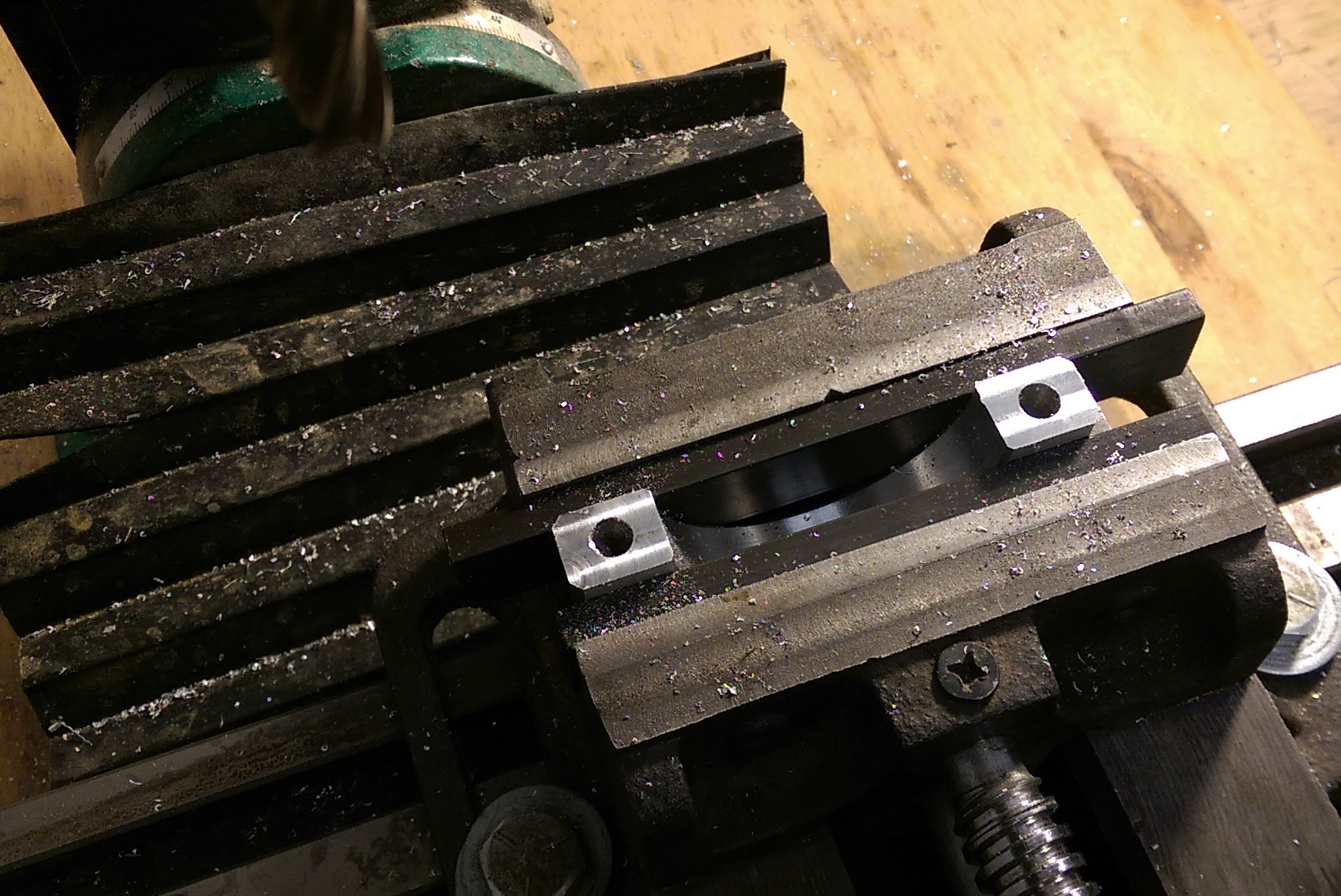

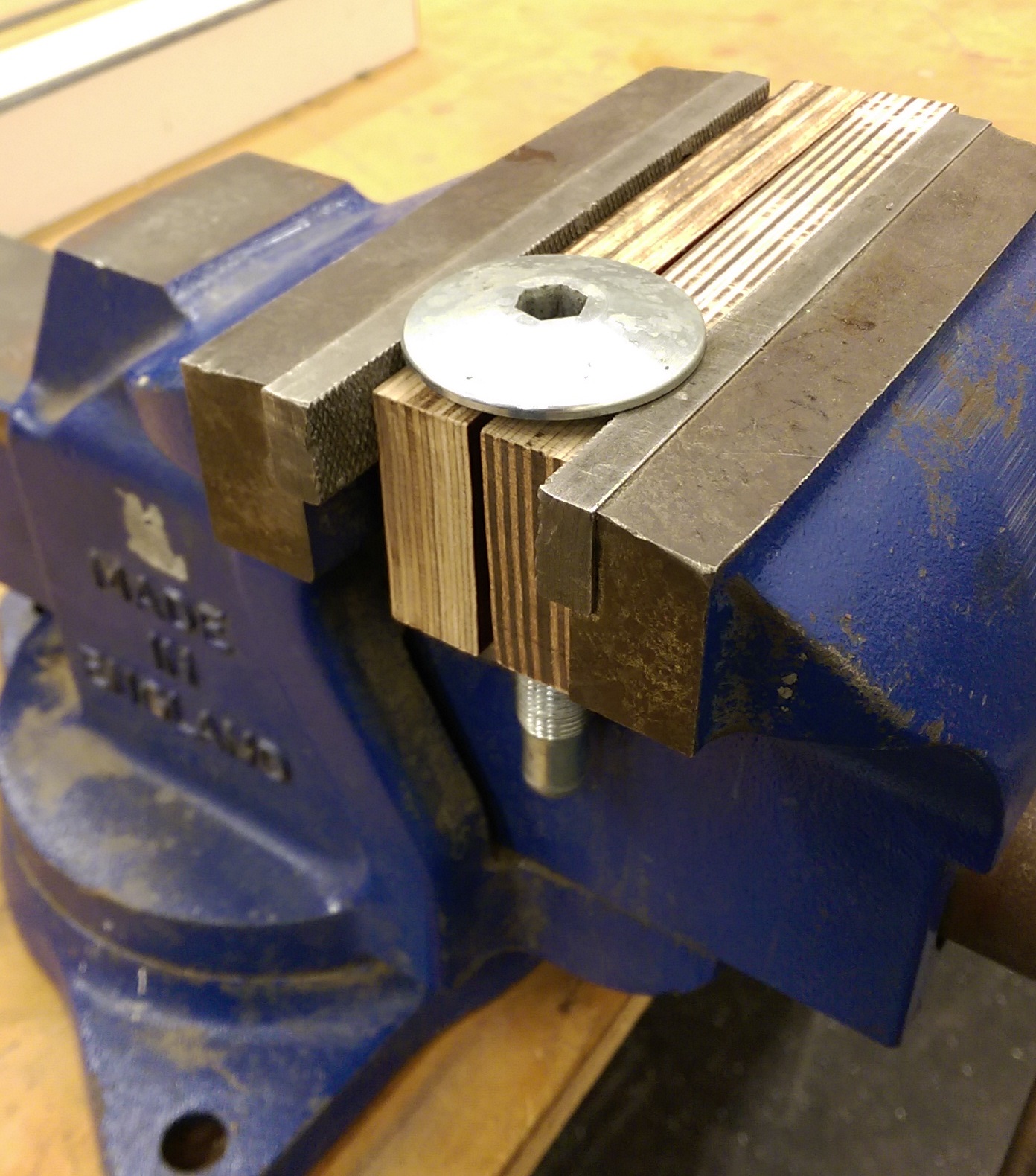

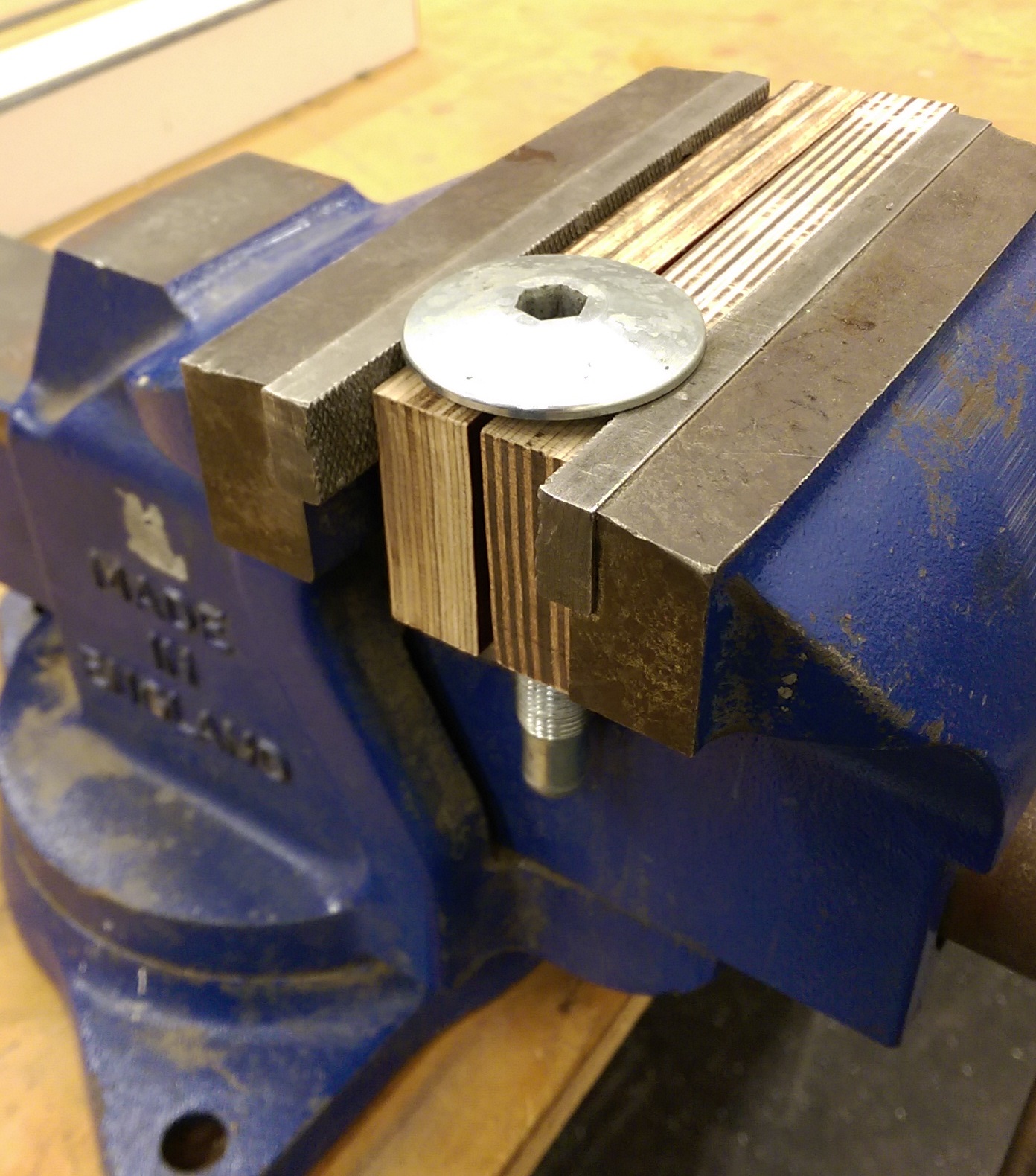

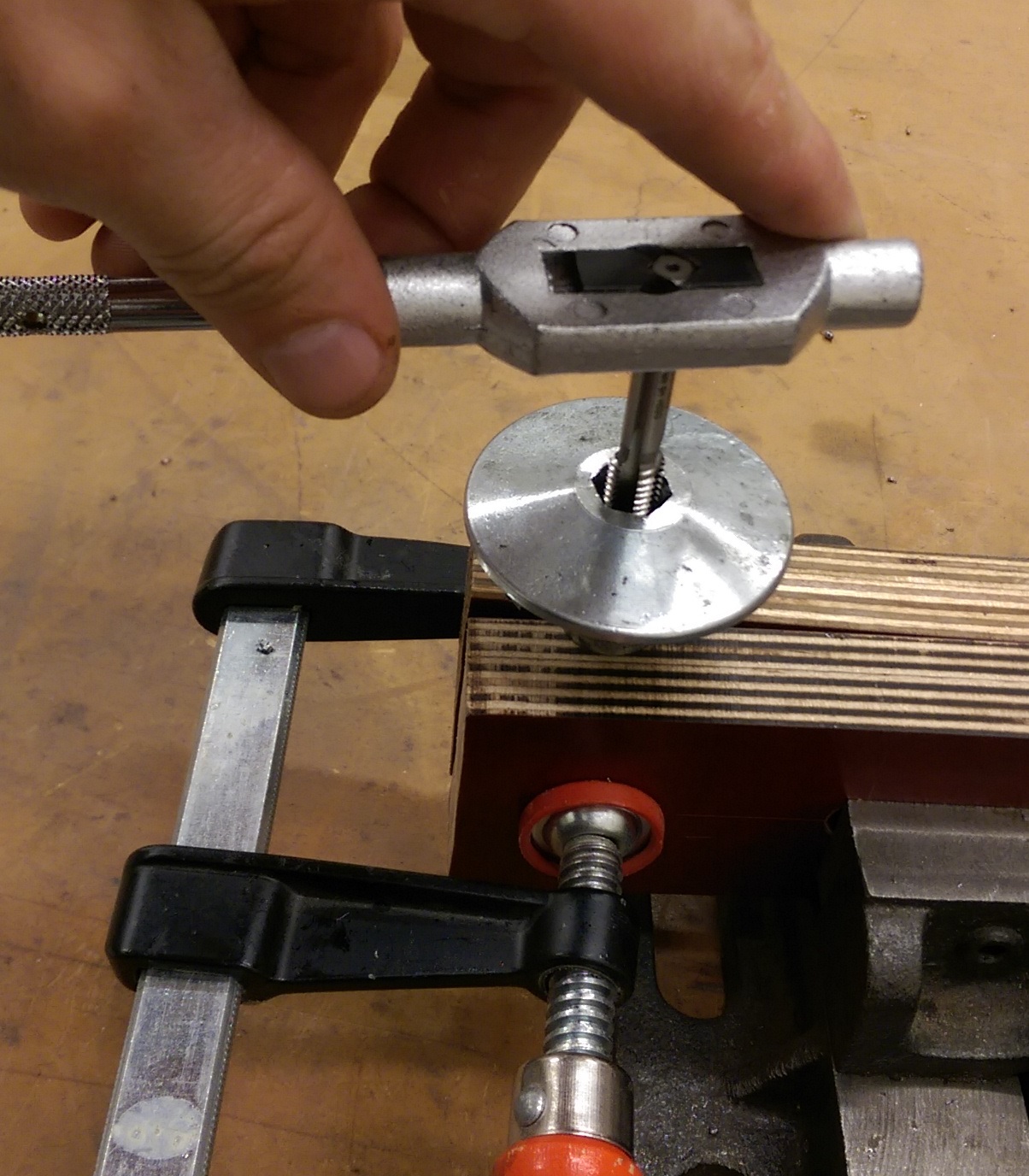

Secure front isolator bolt in a fixture. I used a vise with a couple plywood pieces

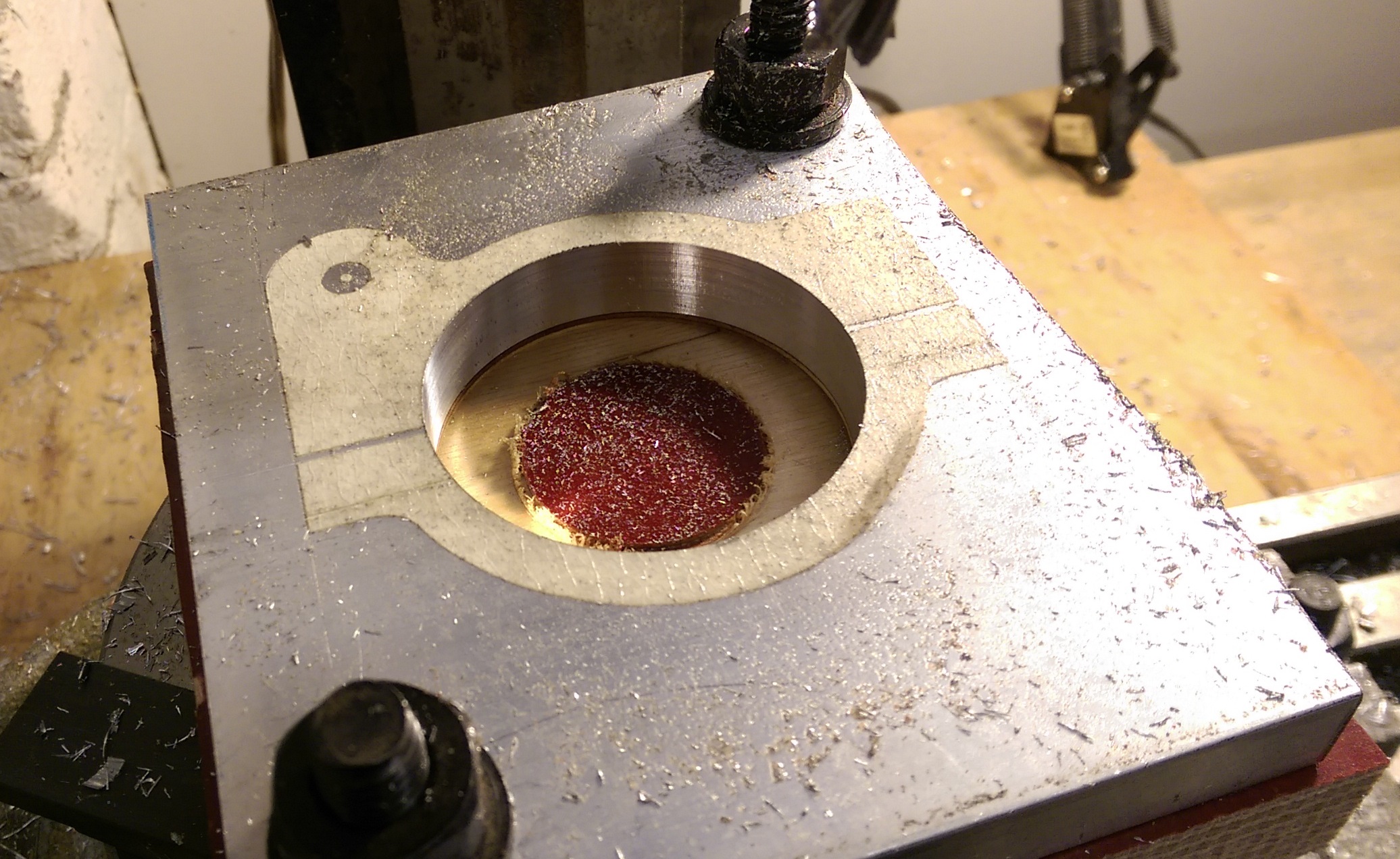

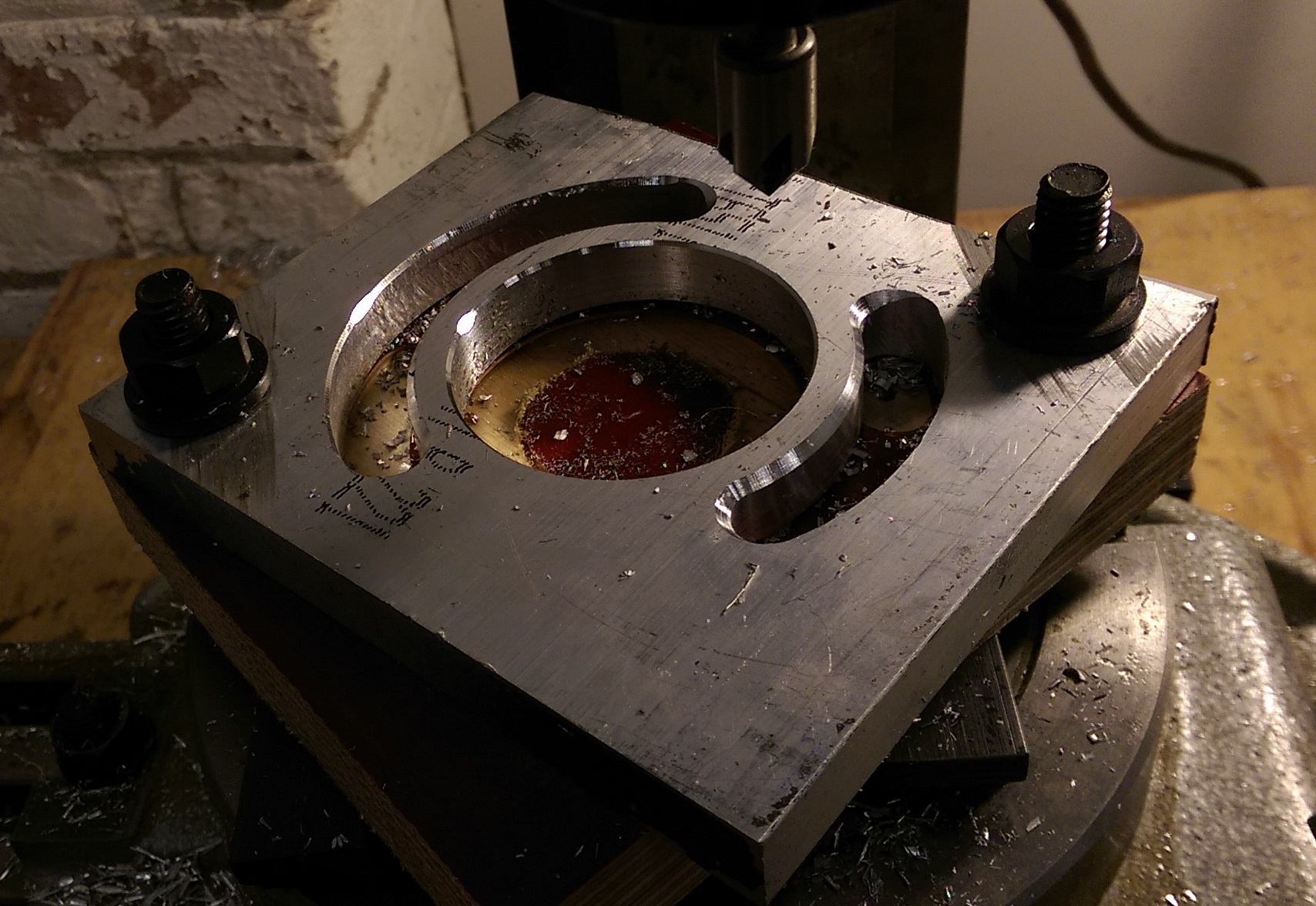

Tap the center mark in the bolt

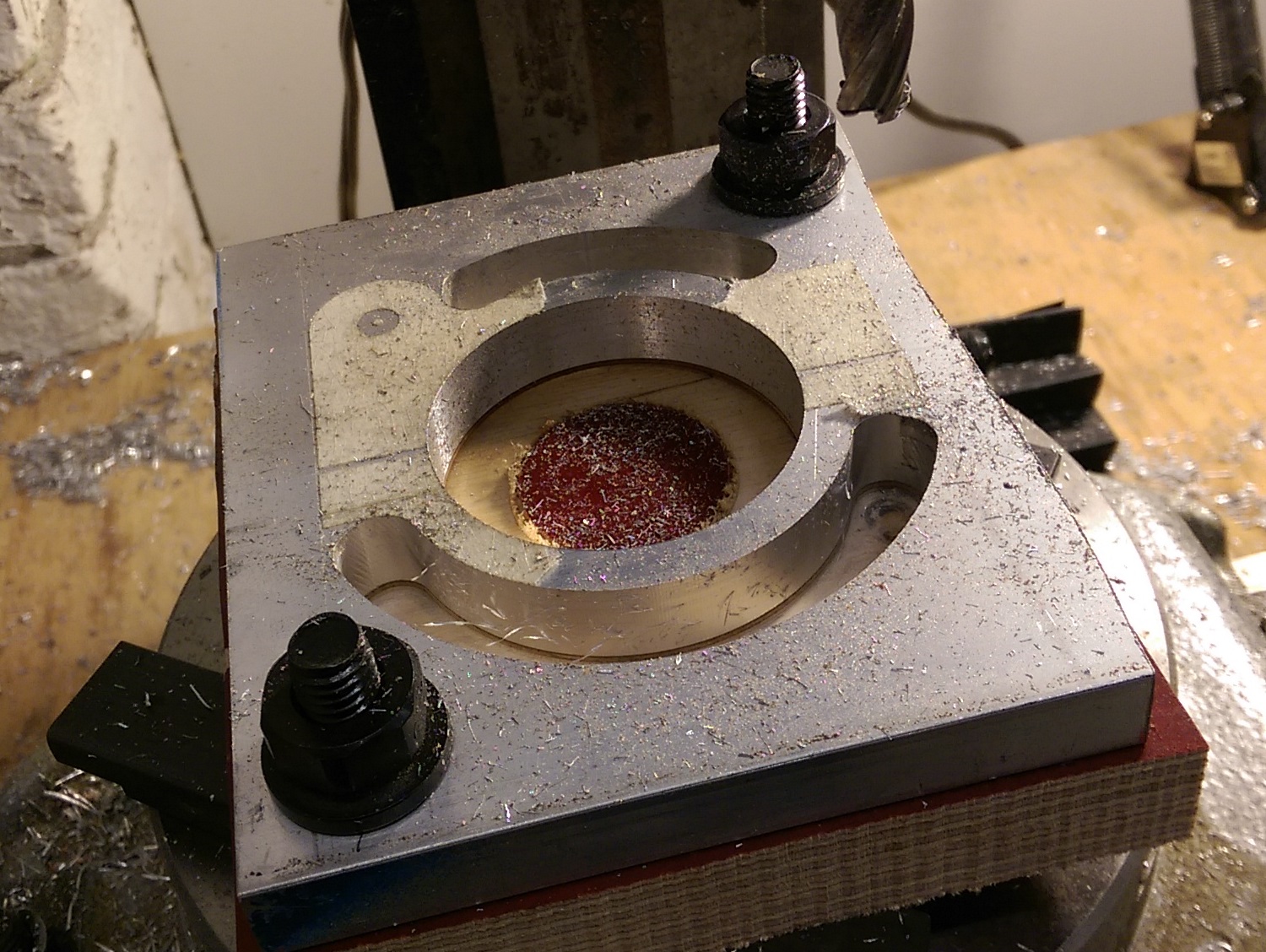

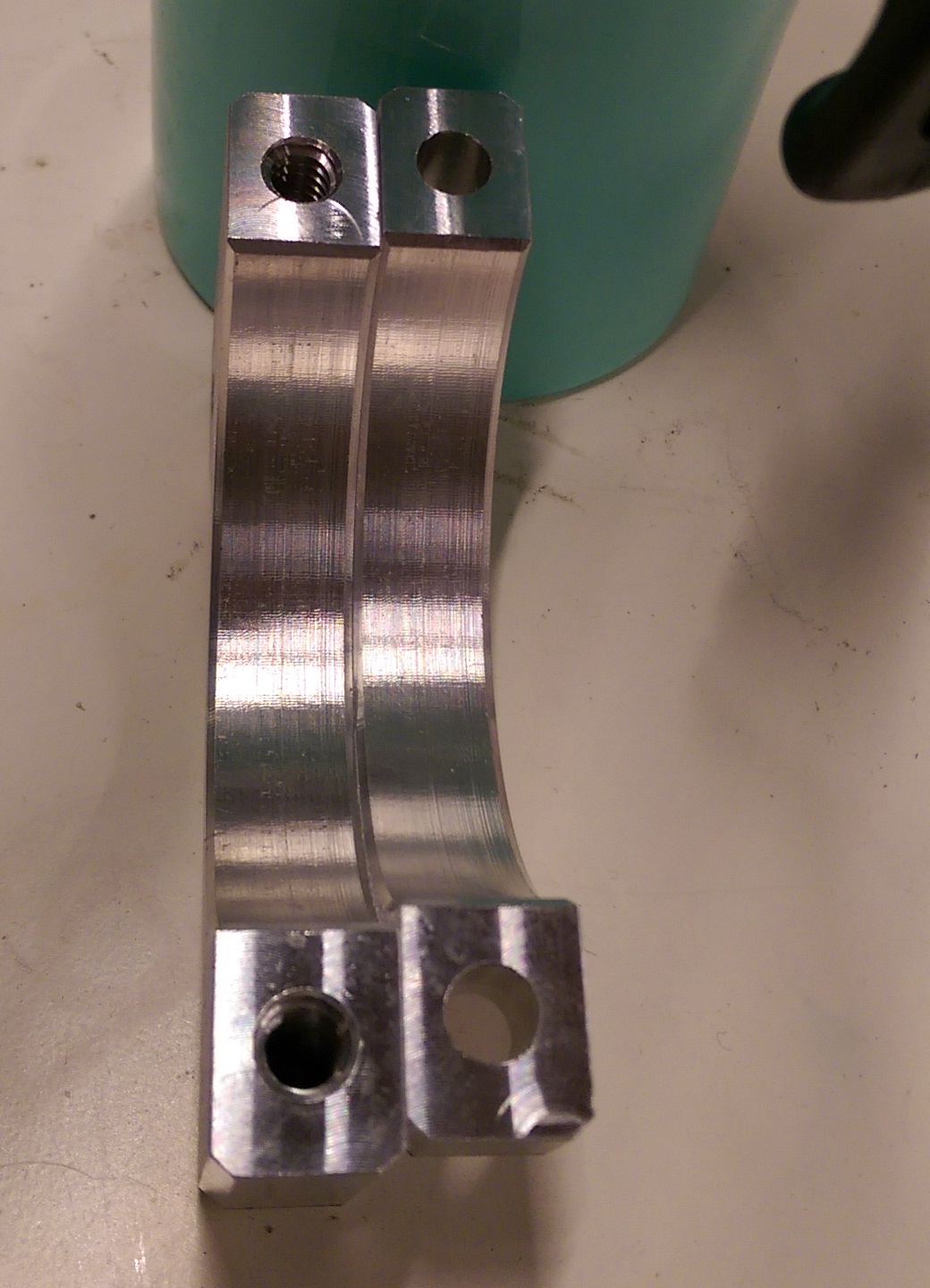

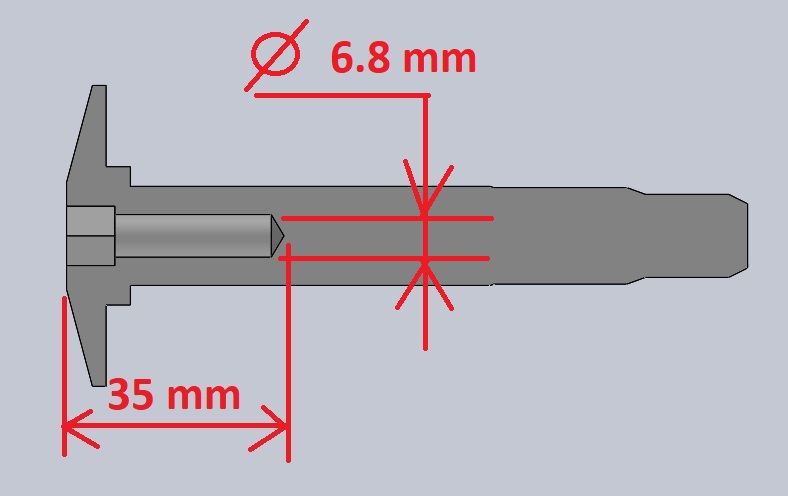

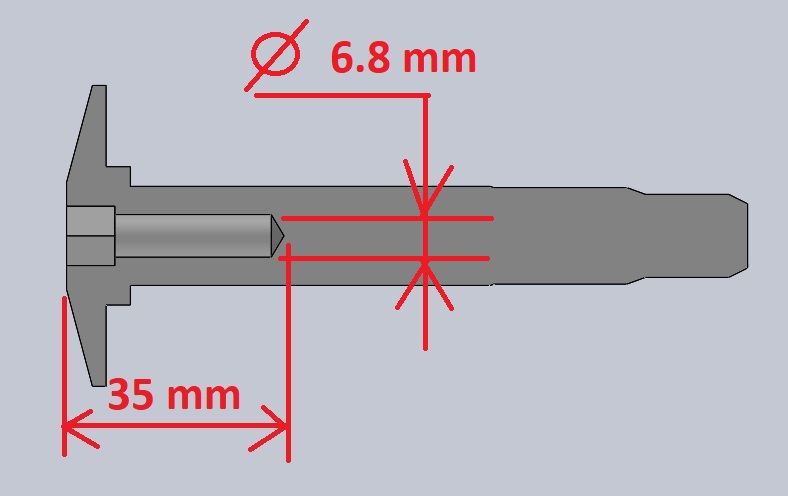

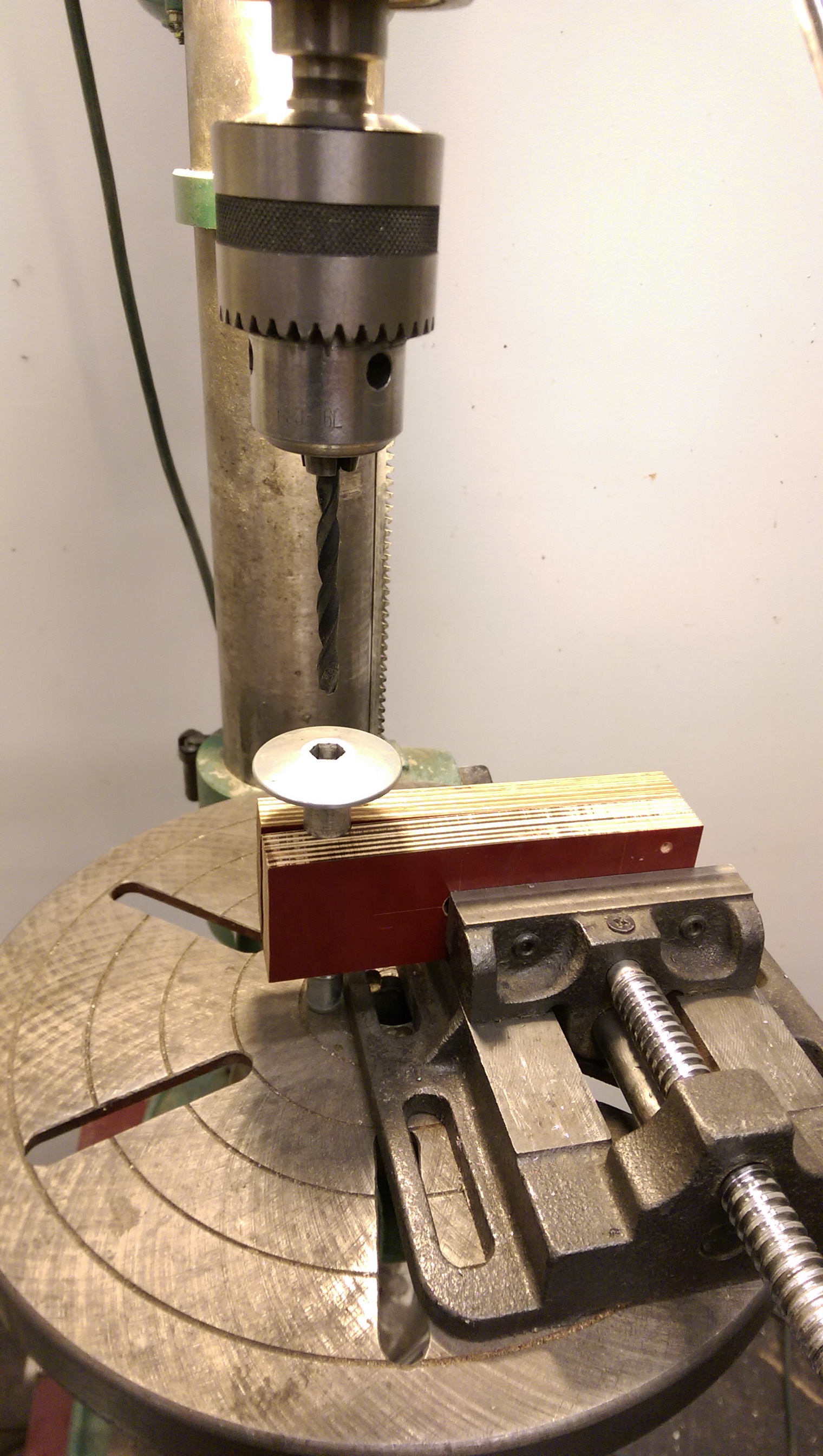

Drill 6.8 mm hole in the bolt to at least 35 mm depth

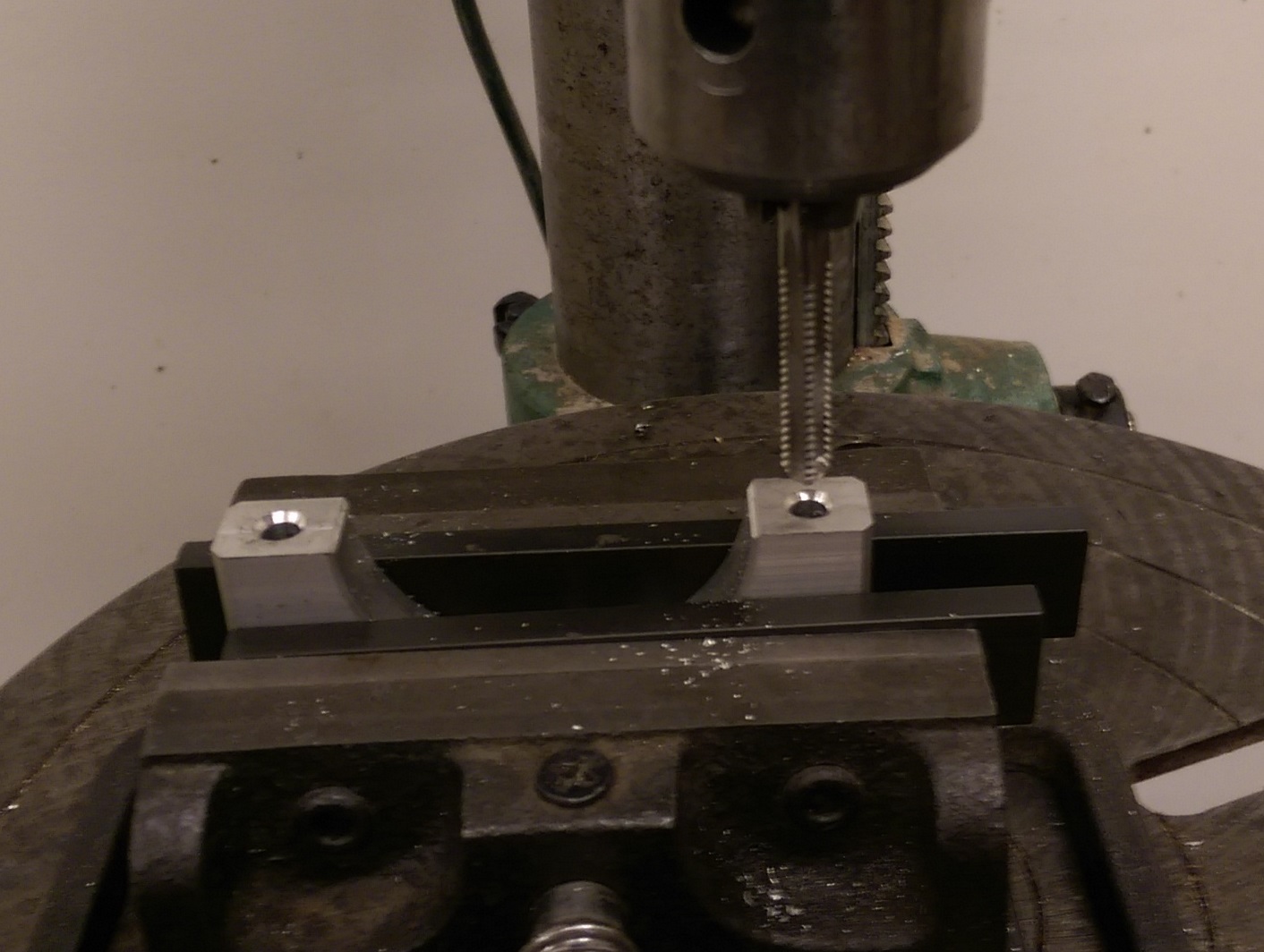

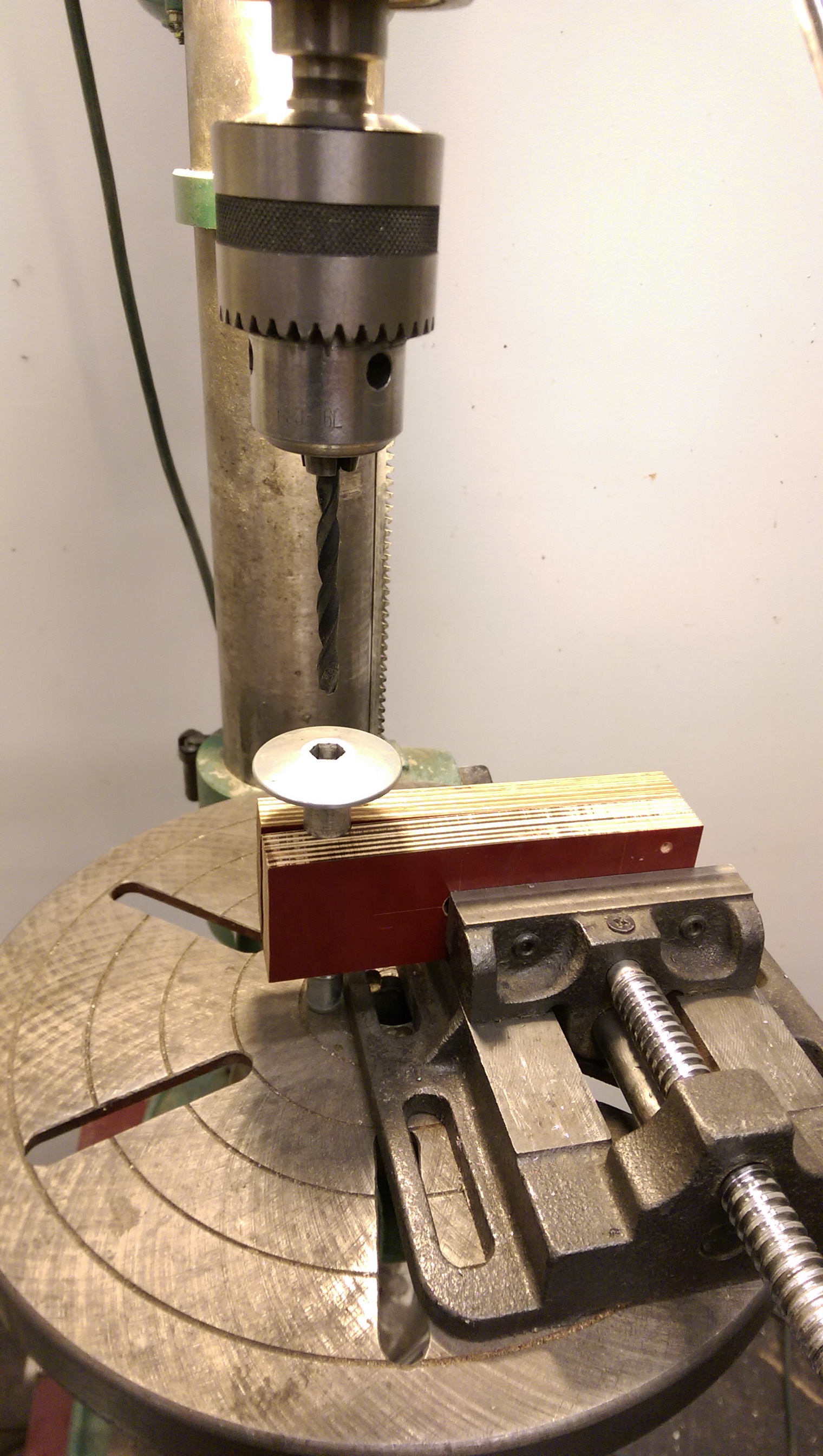

It is very important to drill this hole as parallel to the bolt axis as possible. I used press drill to drill this hole

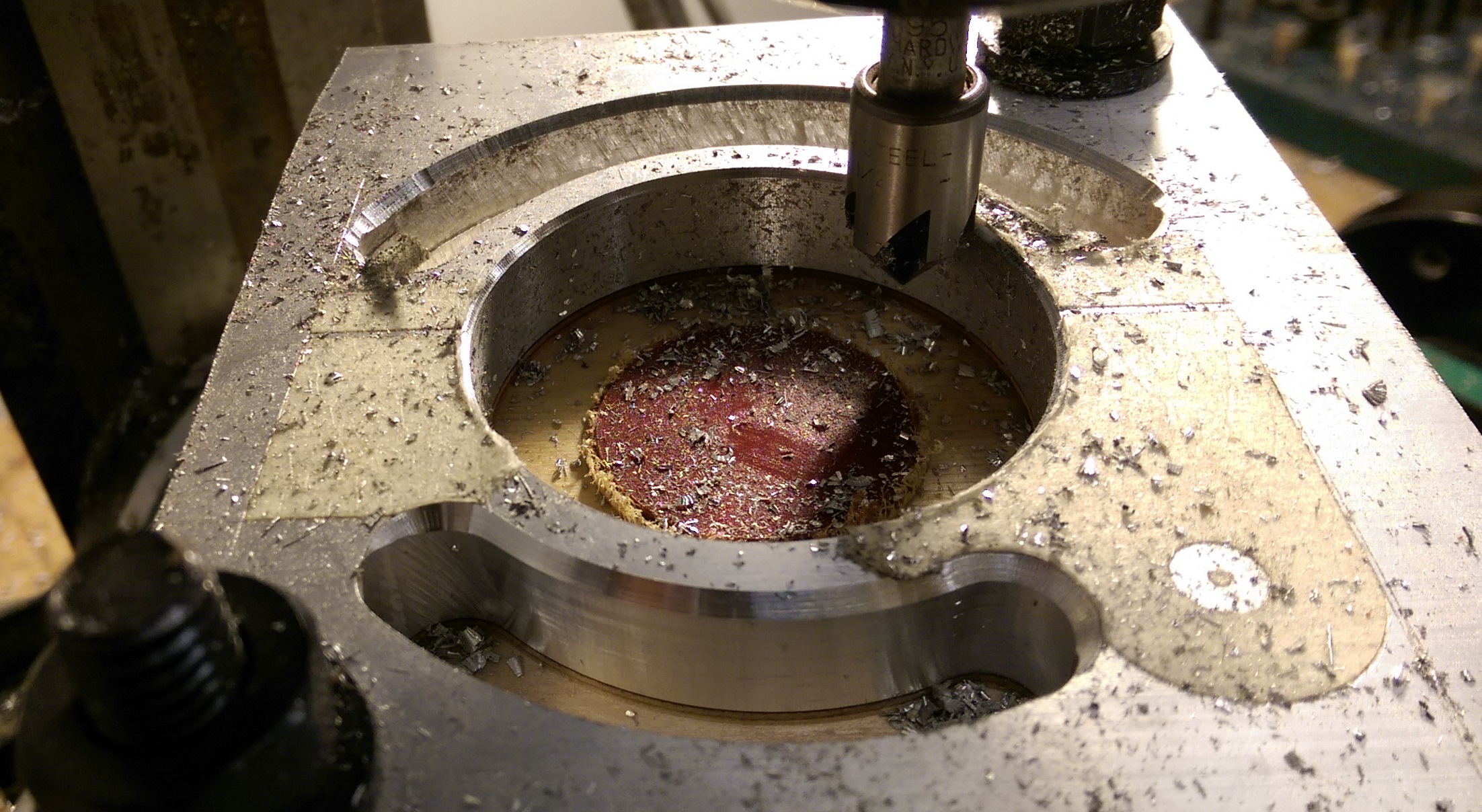

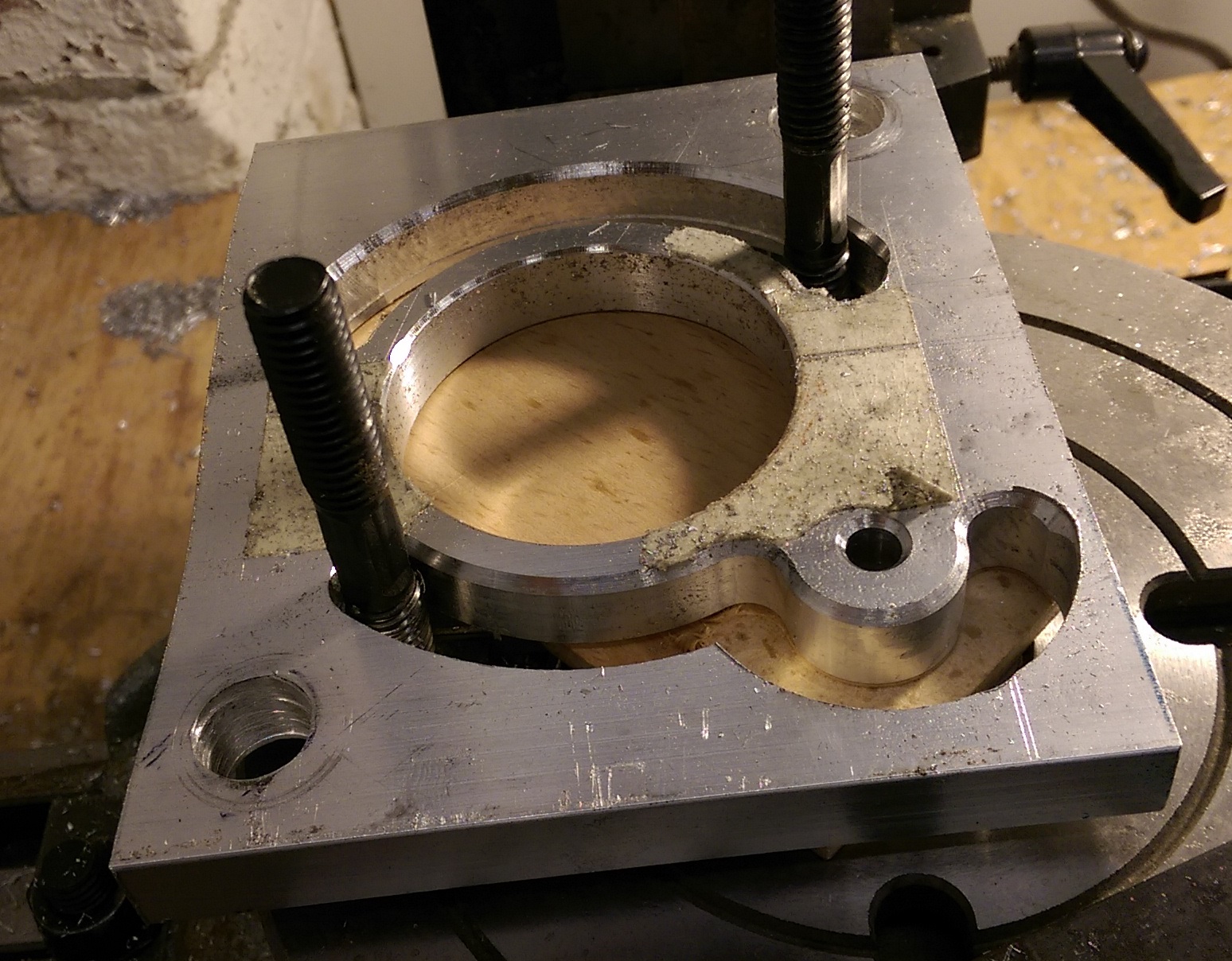

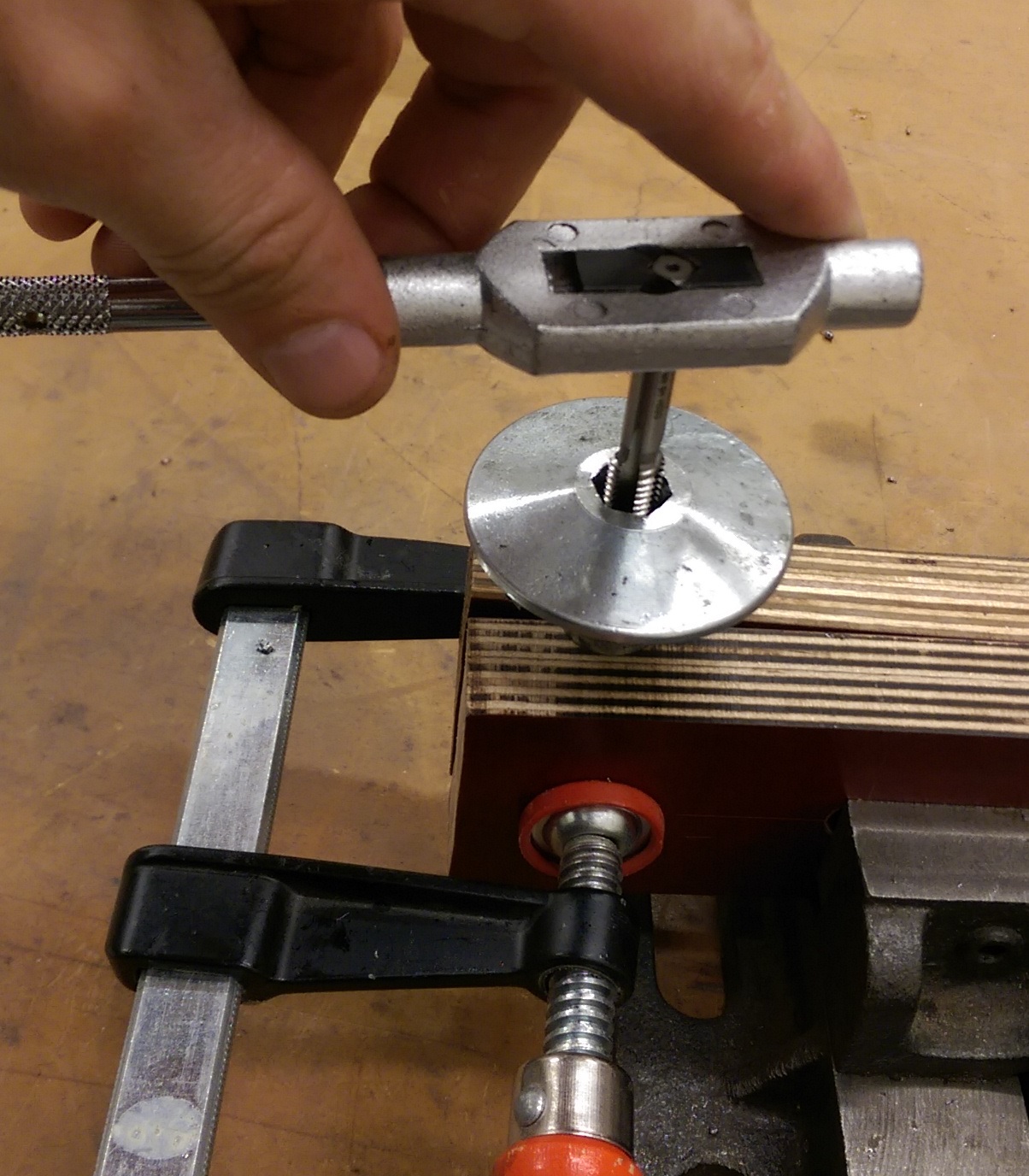

Tap M8 thread in the hole up to the hole bottom.

I started tap hole with M8 beginner tapper using press drill and manually turning it to engage the tapper to the hole as parallel as possible and then finished tapping manually with bottom tapper

Done!

Firs of all a little sneak peek.

My CAD model to check fitments of the steering damper components

Installed damper

Alright. Here is list of parts you will need:

- Steering damper itself, no additional brackets, just $35 damper (you can pick any color you want) https://www.amazon.com/gp/product/B01FMOJ1TO/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- 54 mm diameter steering damper fork clamp (for 2009 Buell XB12Scg diameter is 54 mm, if you have another year motorcycle verify you fork diameter where you are going to attach bracket, if it is different you have to buy bracket with diameter you need) https://www.amazon.com/gp/product/B01N2ZTDL8/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- 2 O-rings 3 mm Wide, 12 mm ID https://www.mcmaster.com/#9262k266/=19kpraa

- 2 O-rings 2 mm Wide, 12.5 mm ID https://www.mcmaster.com/#9262k852/=19kprbs

- One bolt M8 x 1.25 mm Thread, 45 mm Long https://www.mcmaster.com/#92290a446/=19kprbl

- One bolt M8 x 1.25 mm Thread, 85 mm Long https://www.mcmaster.com/#92290a462/=19kprc4

- One spacer 3/4" OD, 1/4" Length, for 5/16" Screw Size https://www.mcmaster.com/#92510a489/=19kprdg

- One spacer 3/4" OD, 2" Length, for 5/16" Screw Size https://www.mcmaster.com/#92510a813/=19kpre0

- One nut M8 x 1.25 mm Thread with nilon insert https://www.mcmaster.com/#94710a104/=19kprdm

Now you can start build you own steering damper kit.

First of all remove front isolator bolt bolt from your motorcycle.

Secure front isolator bolt in a fixture. I used a vise with a couple plywood pieces

Tap the center mark in the bolt

Drill 6.8 mm hole in the bolt to at least 35 mm depth

It is very important to drill this hole as parallel to the bolt axis as possible. I used press drill to drill this hole

Tap M8 thread in the hole up to the hole bottom.

I started tap hole with M8 beginner tapper using press drill and manually turning it to engage the tapper to the hole as parallel as possible and then finished tapping manually with bottom tapper

Done!

Last edited:

As an Amazon Associate we earn from qualifying purchases.