Today I'm going to show you how to perform 10000 miles maintenance on the front fork for 2009 Buell XB12Scg since I did not find a good thread with this information.

To maintain the fork I used:

- Fork compression tool https://www.amazon.com/gp/product/B000GV6UIE/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- Oil level gauge (can be just syringe and a tube from hardware store) https://www.amazon.com/gp/product/B00REQYRO8/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- Seal driver (for 2009 Buell XB12Scg it is 41mm seal driver, can be replaced by plastic pipe from Home Depot ) https://www.amazon.com/gp/product/B005SUVR7C/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- 1 Liter front fork oil (I used viscosity W15 this time) https://www.amazon.com/gp/product/B0045LCE6S/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- Tools to remove the fork from motorcycle and disassembling (wrenches, motorcycle stands, screwdrivers, e.t.c)

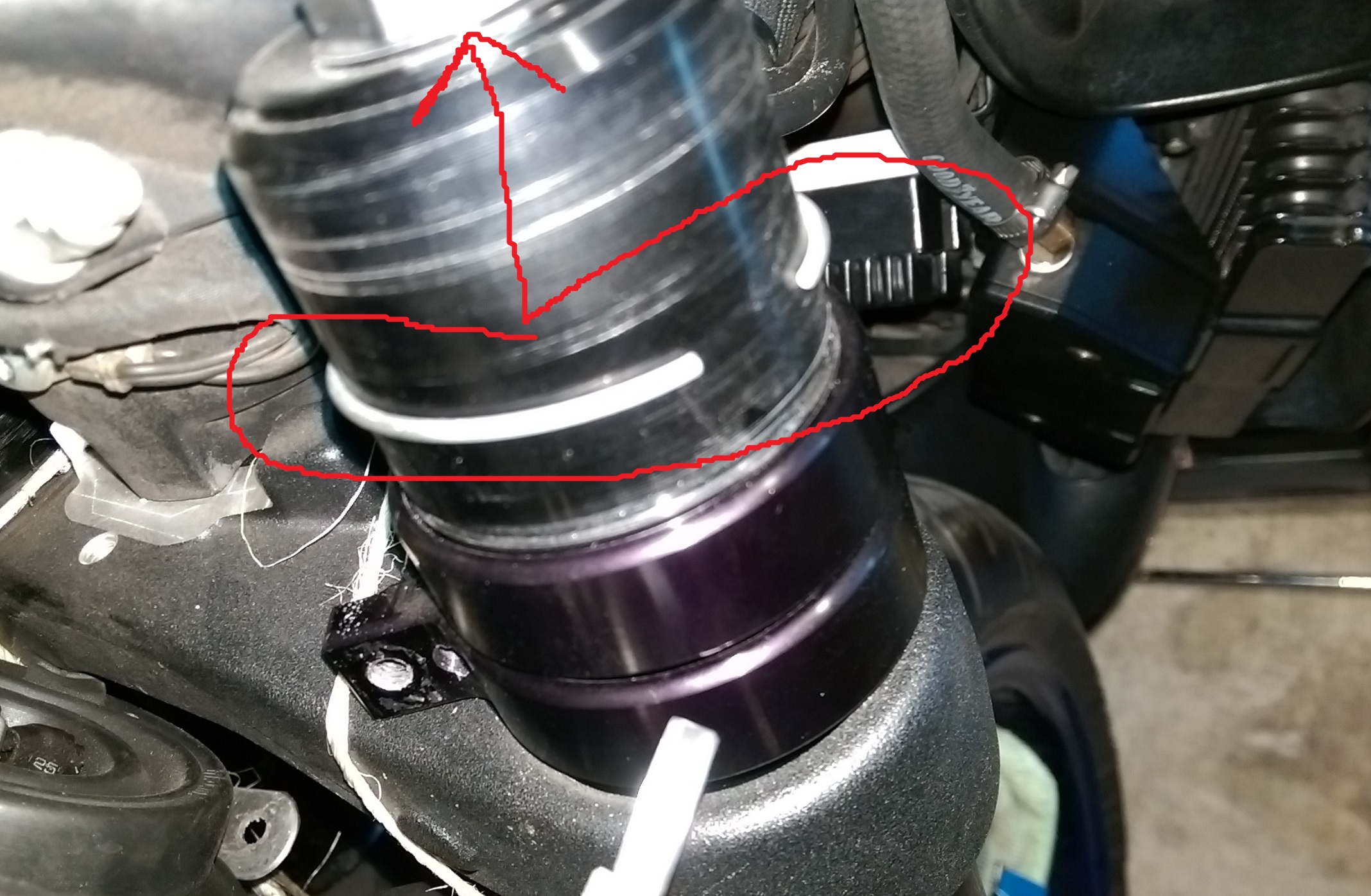

Here is parts list specifically for 2009 Buell XB12Scg you probably also will need to replace while front fork maintenance

- J8138.02A8 GENUINE BUELL FRONT FORK SLIDE BUSHING

https://www.sphdonline.com/products/j8138-02a8-genuine-buell-front-fork-dust-seal-b1p

- J8140.02A8 GENUINE BUELL FRONT FORK GUIDE BUSHING

https://www.sphdonline.com/products/copy-of-j8130-02a8-genuine-buell-front-fork-dust-seal-b1p

- 41-7180 ALL BALLS FORK SEAL KIT

https://www.sphdonline.com/products...al-kit-for-2008-2010-1125r-cr-2008-2010-xb12x

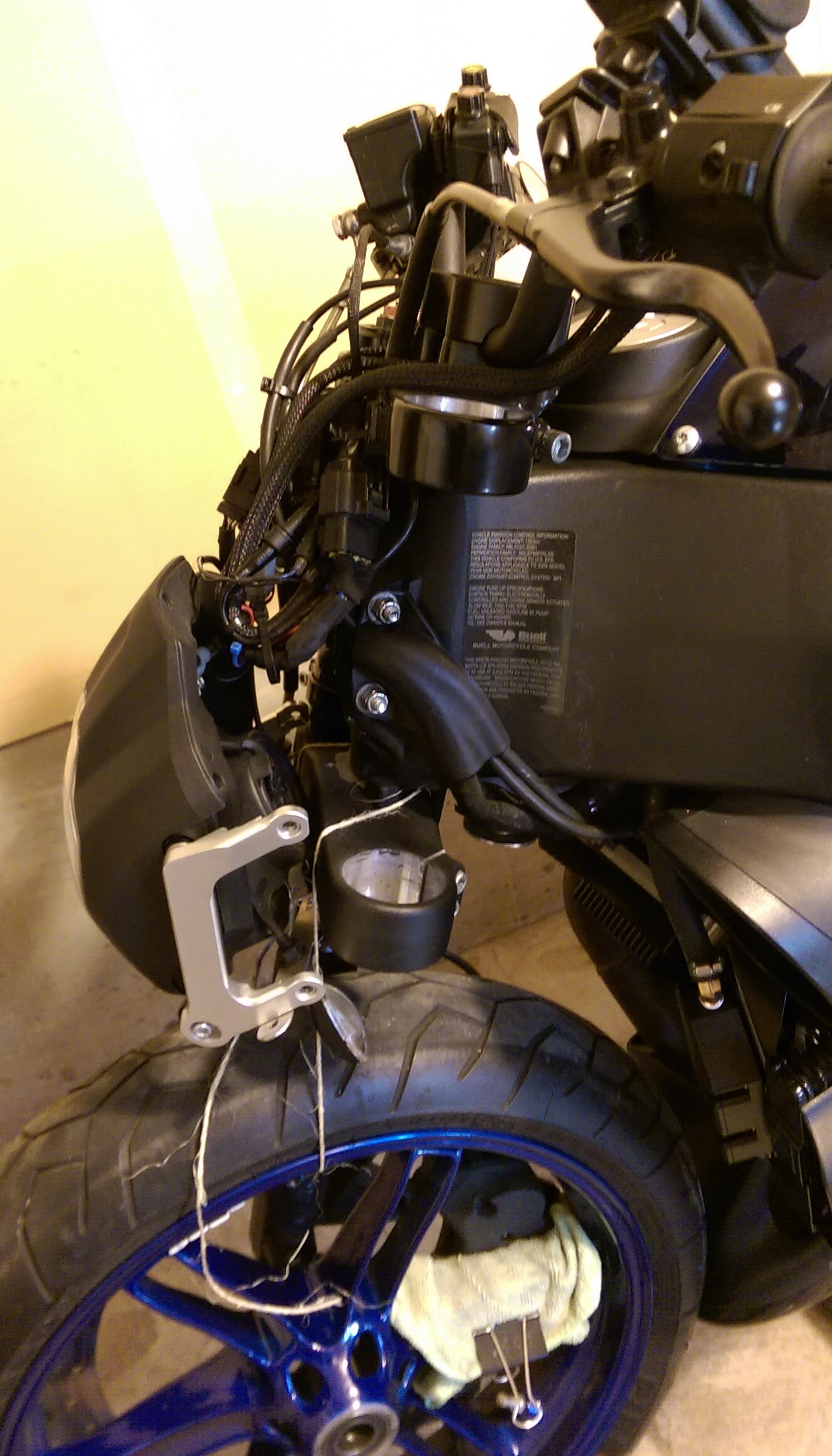

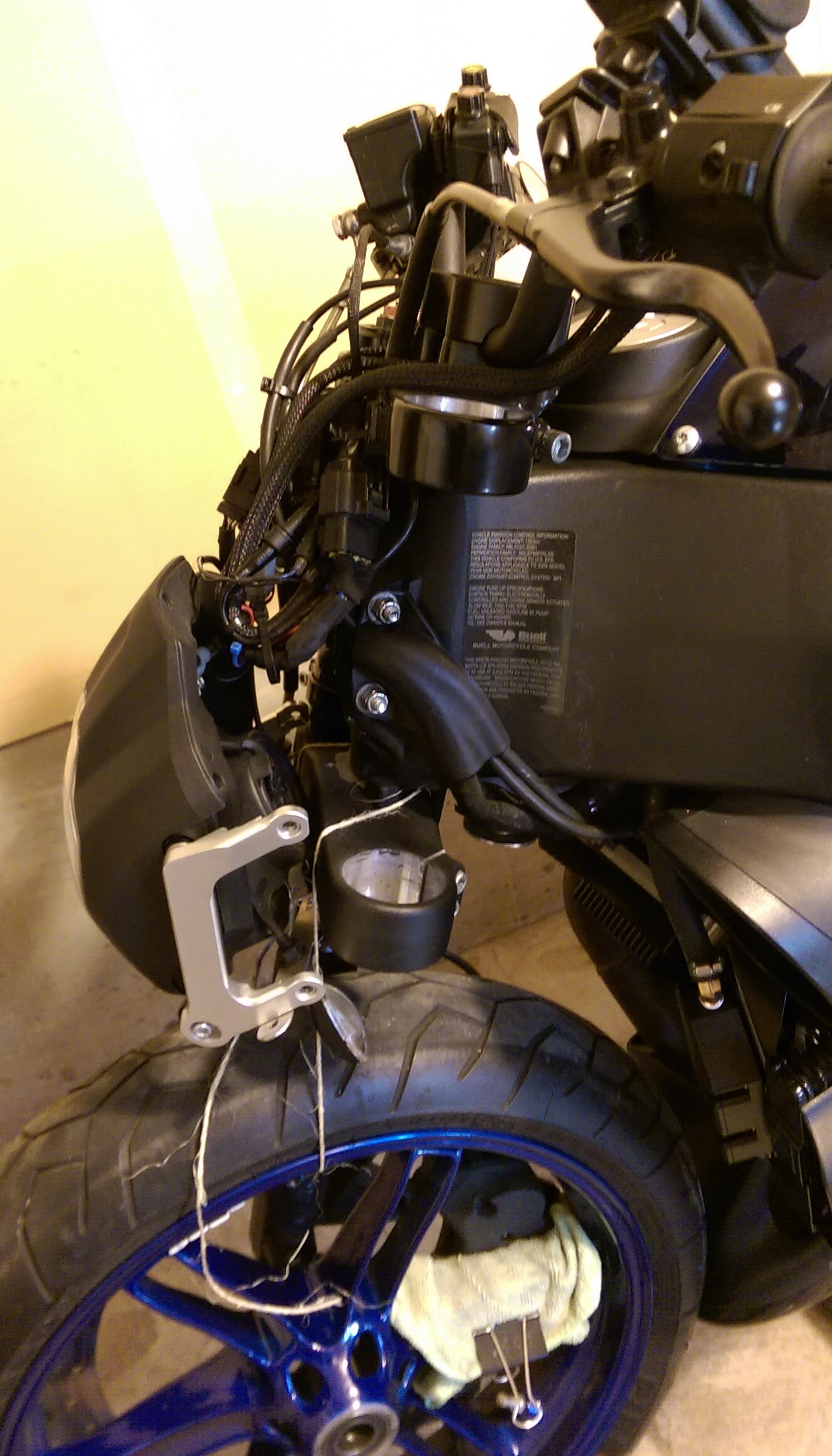

Put motorcycle on muffler jack

Unscrew and remove front wheel fender

Support the front wheel (I used car jack)

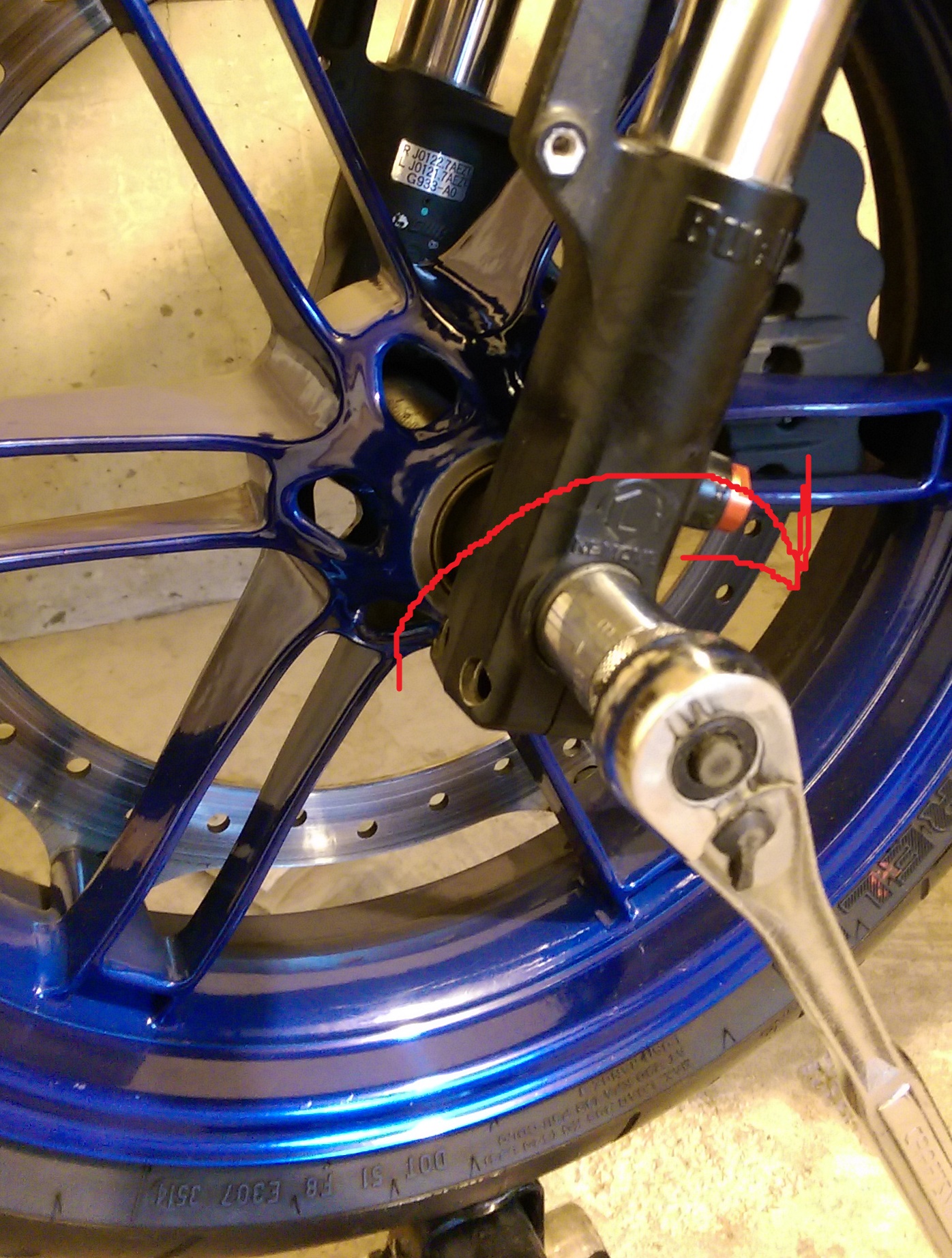

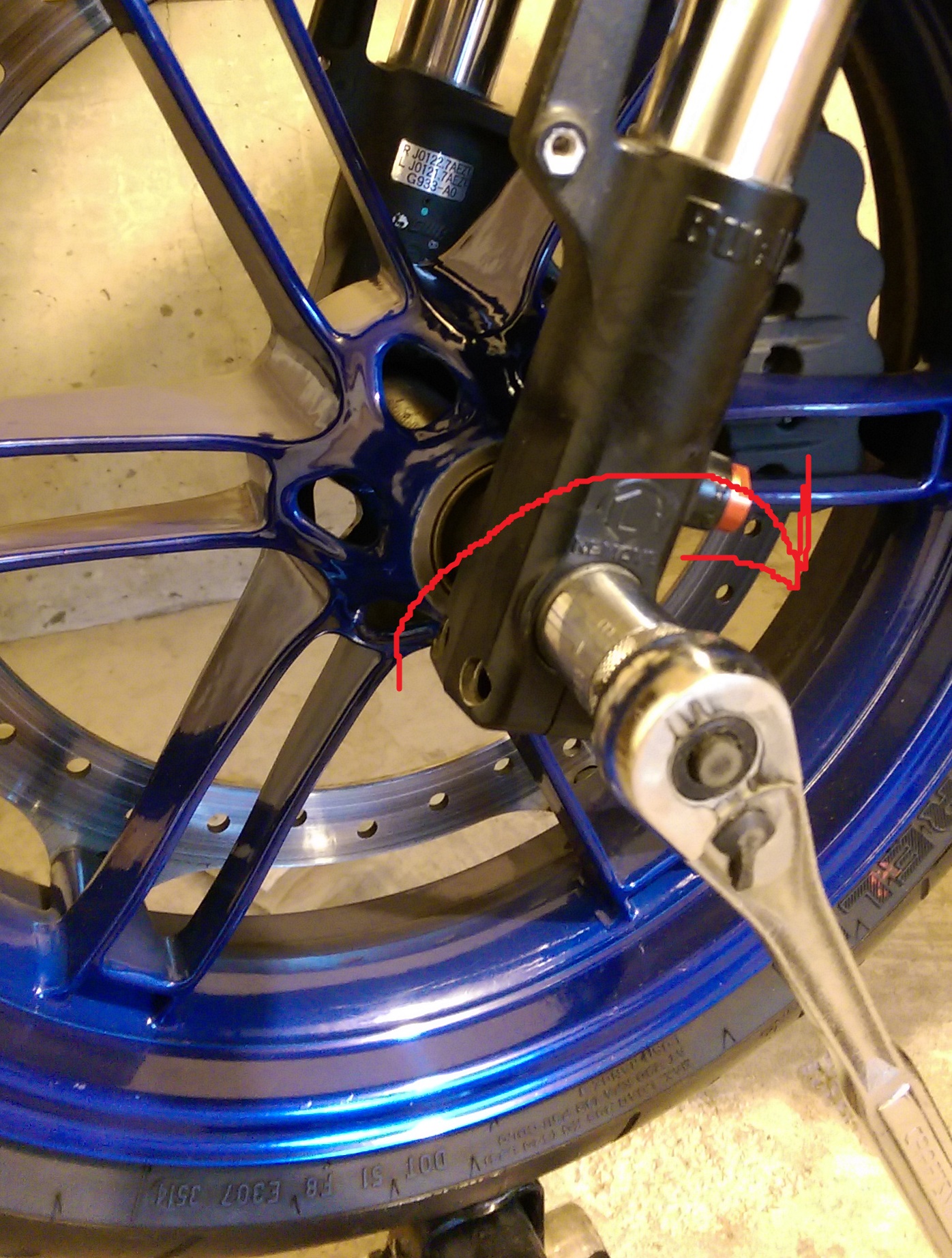

Unscrew two pinch bolts of the wheel axle

Unscrew wheel axle

Wrap the wheel spoke behind the brake caliper with towel

Unscrew the brake caliper

Hang up the front wheel on triple tree bracket

Remove front wheel support

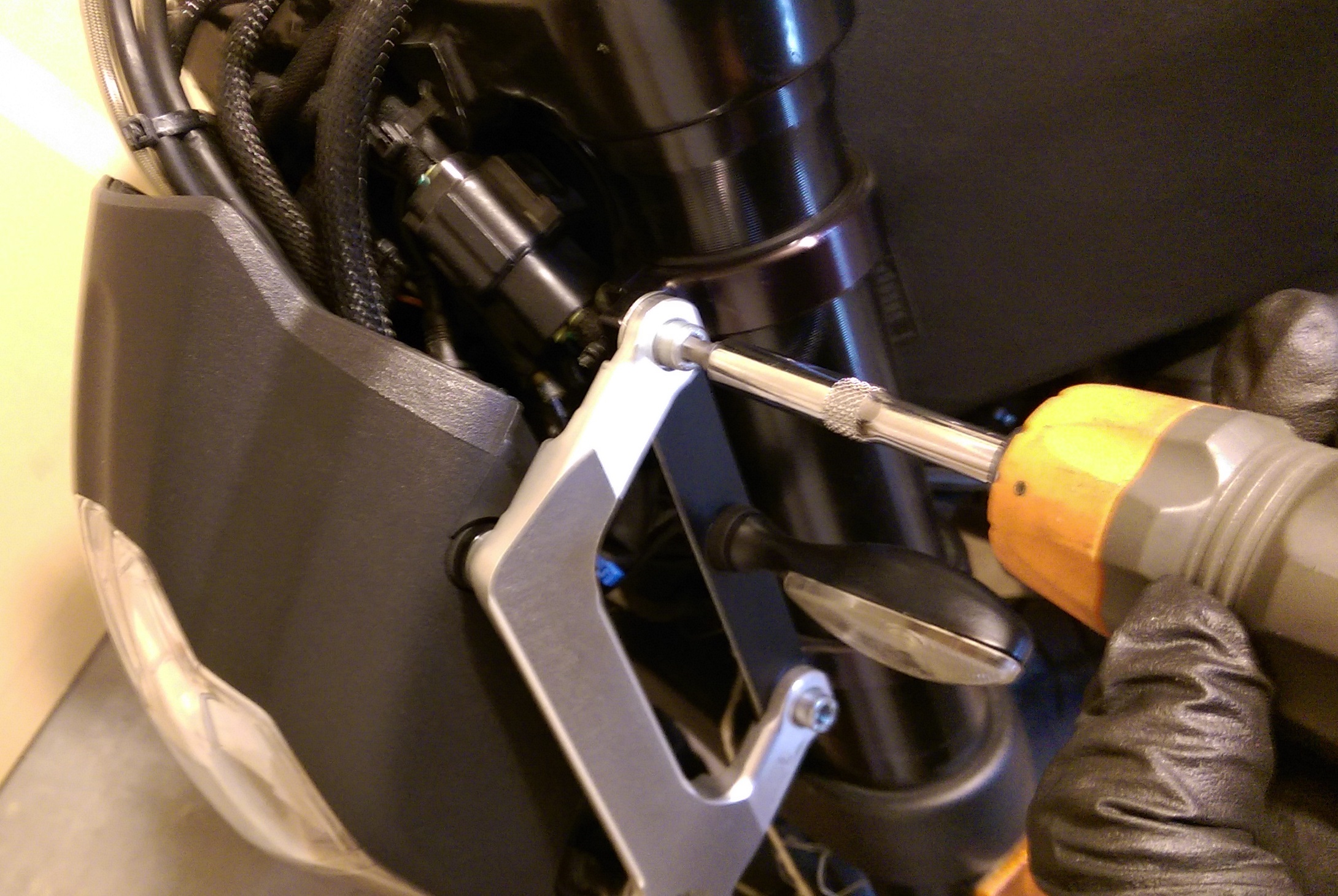

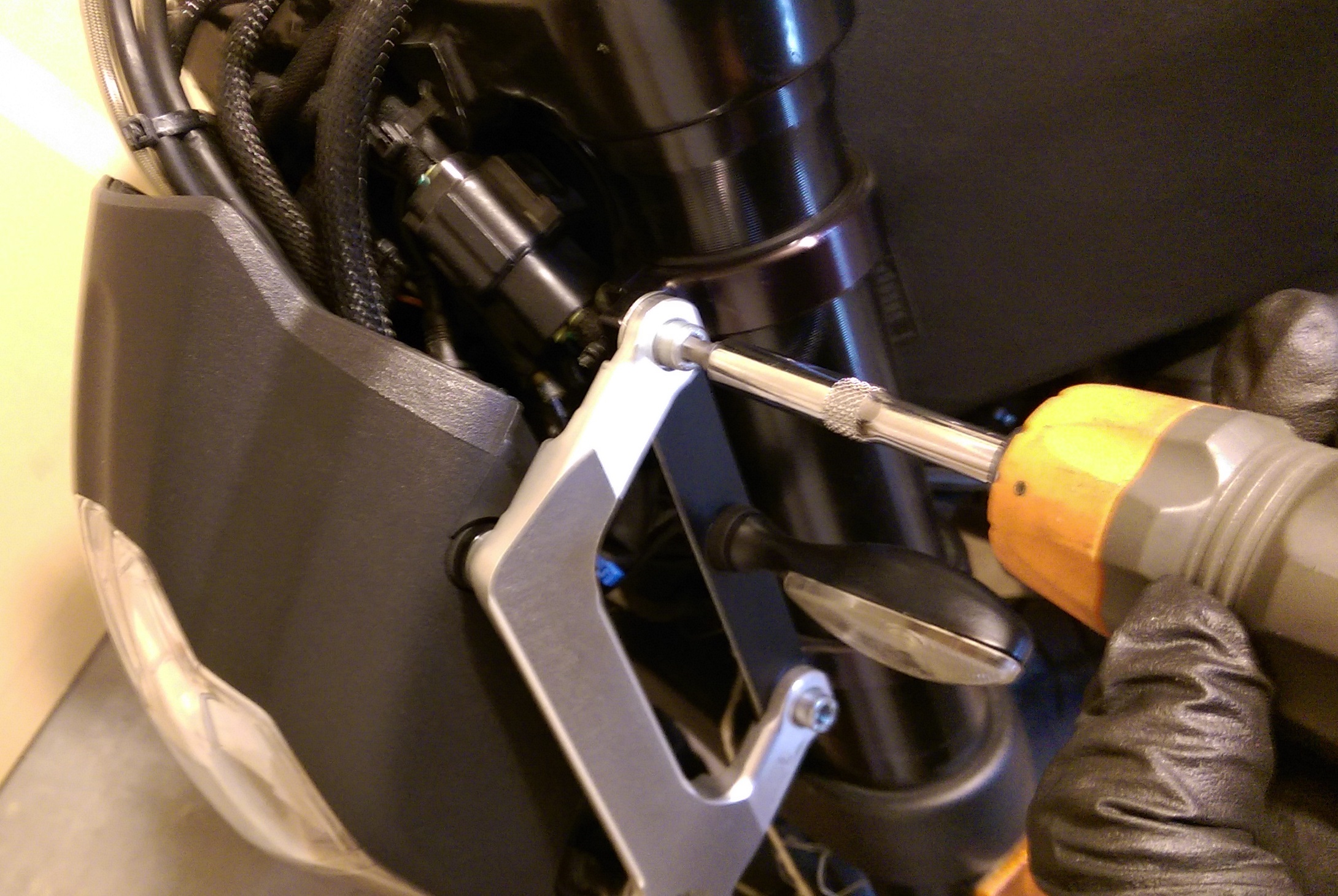

Remove headlight assembly from front forks to be able to remove the forks

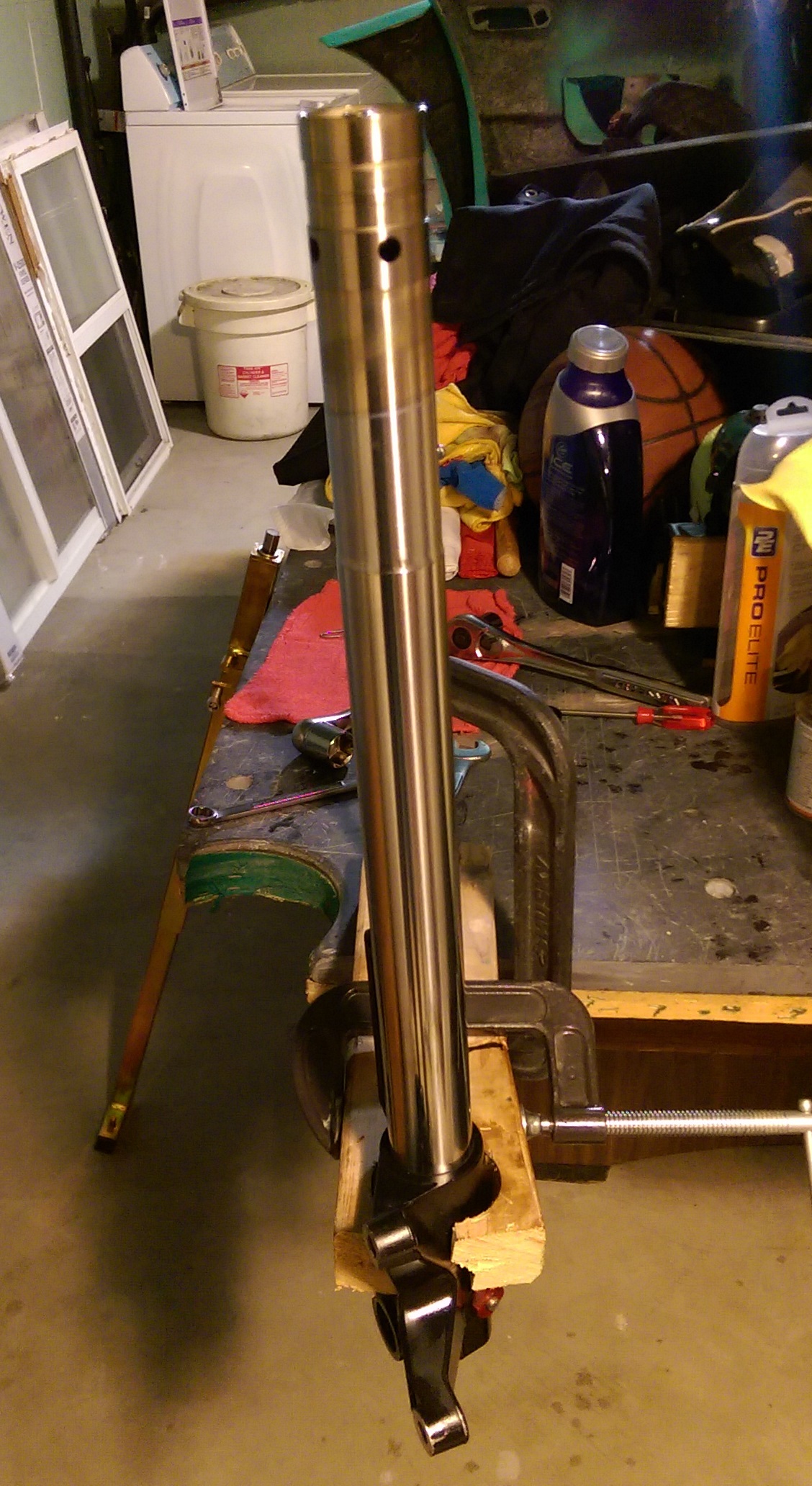

Unscrew the forks from triple tree clamps

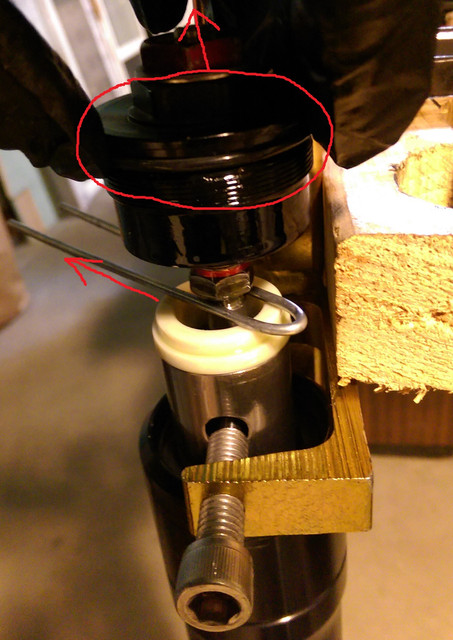

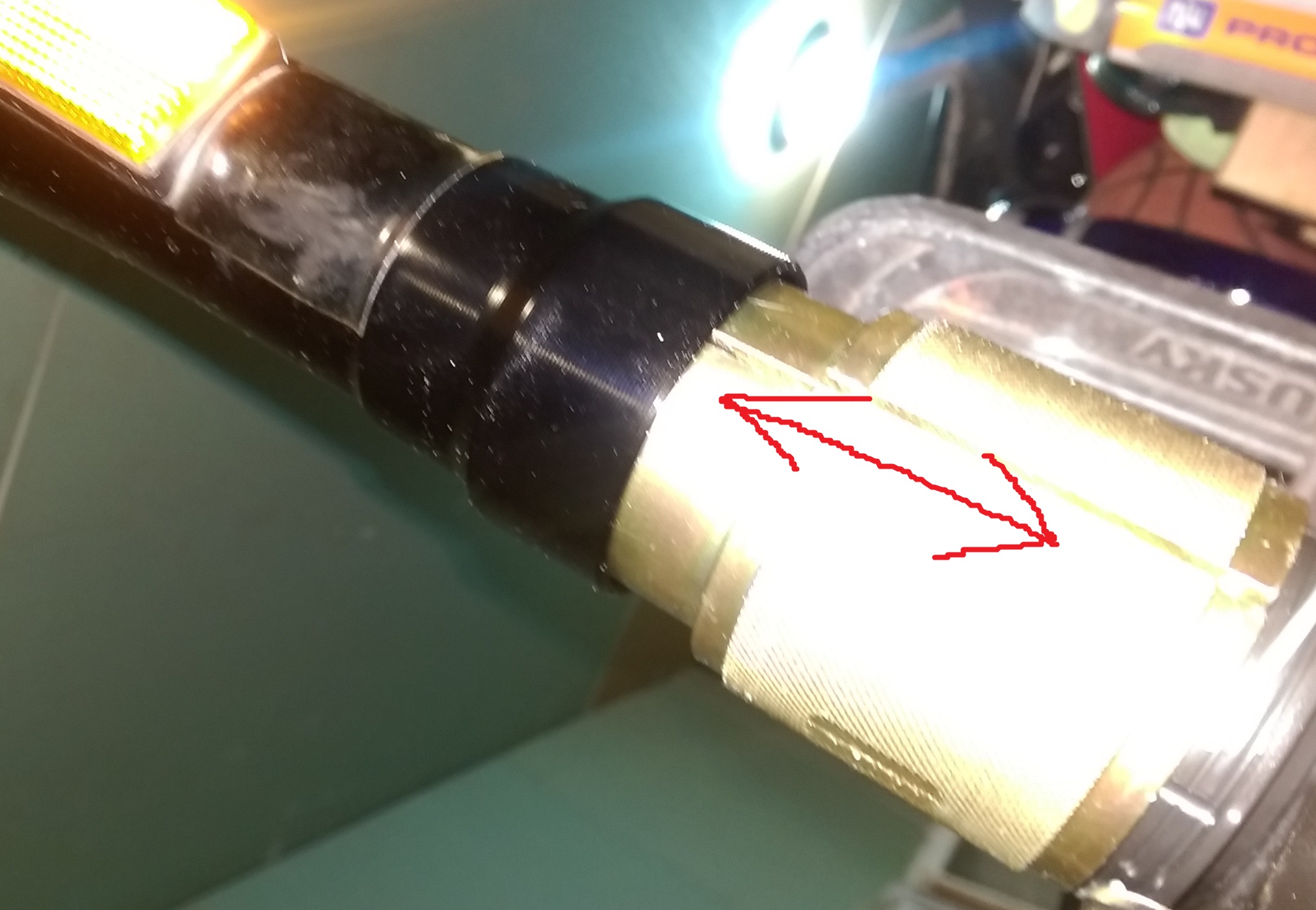

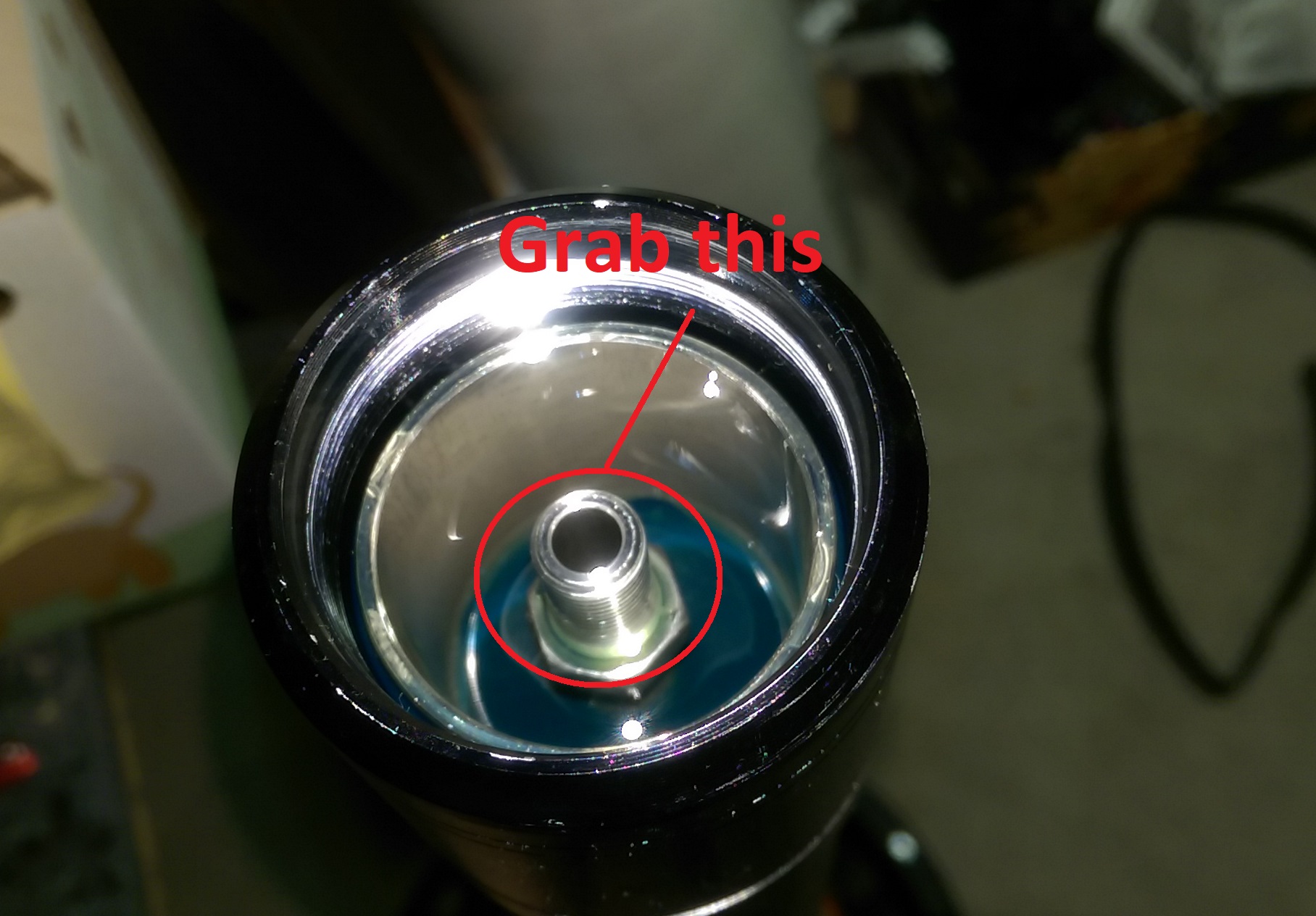

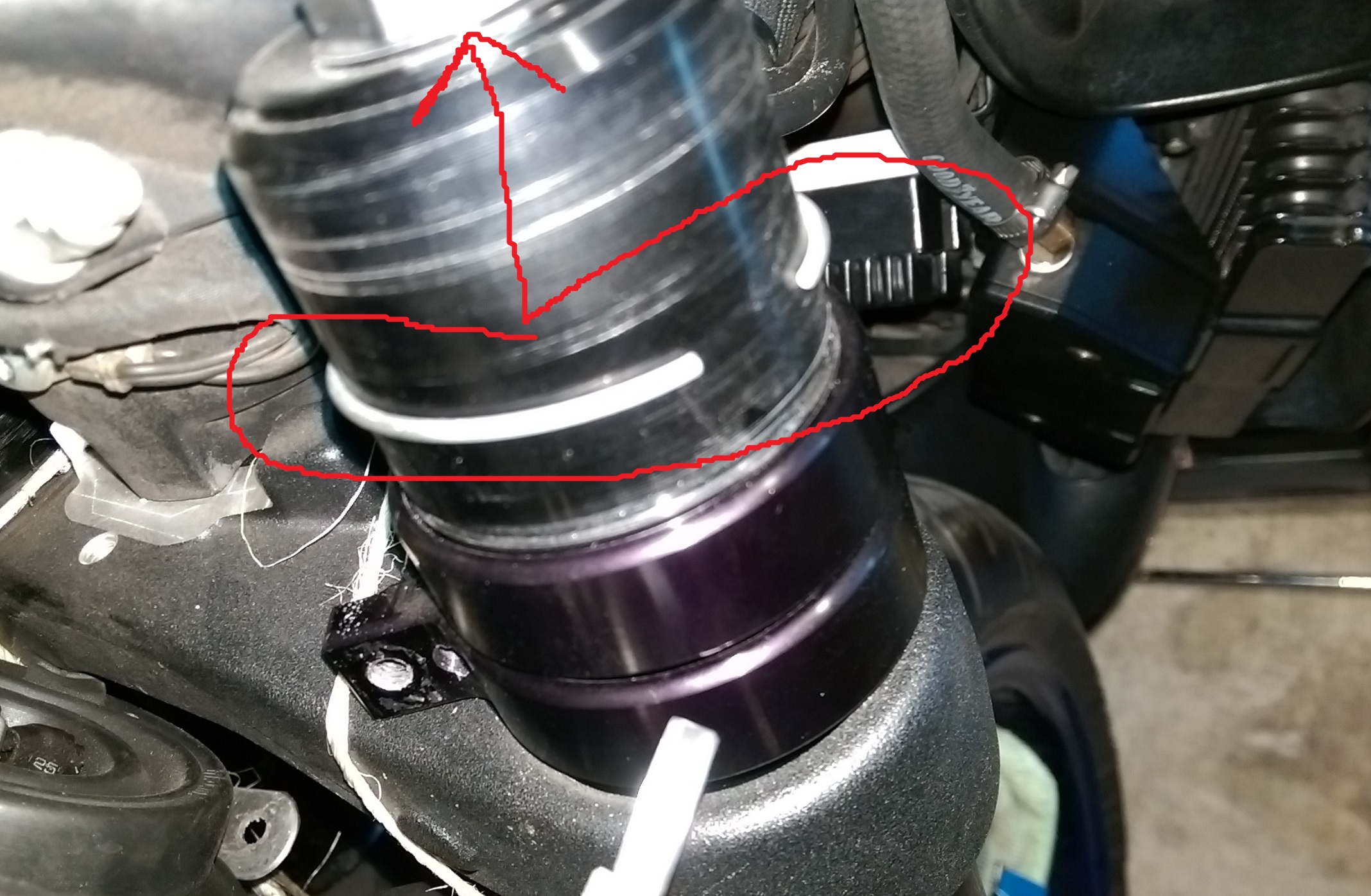

Slide fork down from the top triple tree clamp, remove retaining ring on the top side of the fork, slide the fork completely down from the lowed triple tree clamp

To maintain the fork I used:

- Fork compression tool https://www.amazon.com/gp/product/B000GV6UIE/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- Oil level gauge (can be just syringe and a tube from hardware store) https://www.amazon.com/gp/product/B00REQYRO8/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- Seal driver (for 2009 Buell XB12Scg it is 41mm seal driver, can be replaced by plastic pipe from Home Depot ) https://www.amazon.com/gp/product/B005SUVR7C/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- 1 Liter front fork oil (I used viscosity W15 this time) https://www.amazon.com/gp/product/B0045LCE6S/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- Tools to remove the fork from motorcycle and disassembling (wrenches, motorcycle stands, screwdrivers, e.t.c)

Here is parts list specifically for 2009 Buell XB12Scg you probably also will need to replace while front fork maintenance

- J8138.02A8 GENUINE BUELL FRONT FORK SLIDE BUSHING

https://www.sphdonline.com/products/j8138-02a8-genuine-buell-front-fork-dust-seal-b1p

- J8140.02A8 GENUINE BUELL FRONT FORK GUIDE BUSHING

https://www.sphdonline.com/products/copy-of-j8130-02a8-genuine-buell-front-fork-dust-seal-b1p

- 41-7180 ALL BALLS FORK SEAL KIT

https://www.sphdonline.com/products...al-kit-for-2008-2010-1125r-cr-2008-2010-xb12x

Put motorcycle on muffler jack

Unscrew and remove front wheel fender

Support the front wheel (I used car jack)

Unscrew two pinch bolts of the wheel axle

Unscrew wheel axle

Wrap the wheel spoke behind the brake caliper with towel

Unscrew the brake caliper

Hang up the front wheel on triple tree bracket

Remove front wheel support

Remove headlight assembly from front forks to be able to remove the forks

Unscrew the forks from triple tree clamps

Slide fork down from the top triple tree clamp, remove retaining ring on the top side of the fork, slide the fork completely down from the lowed triple tree clamp

Last edited:

As an Amazon Associate we earn from qualifying purchases.