SEXT9

Well-known member

We've been talking about creating a new right side scoop on another thread HERE. I don't know about everyone else. But, I'm tired of having non-matching left and right side scoops. From the front it's almost like looking at a woman with severely mismatched breasts.

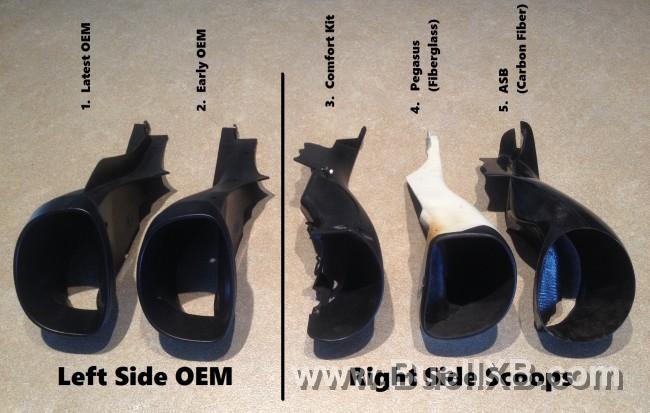

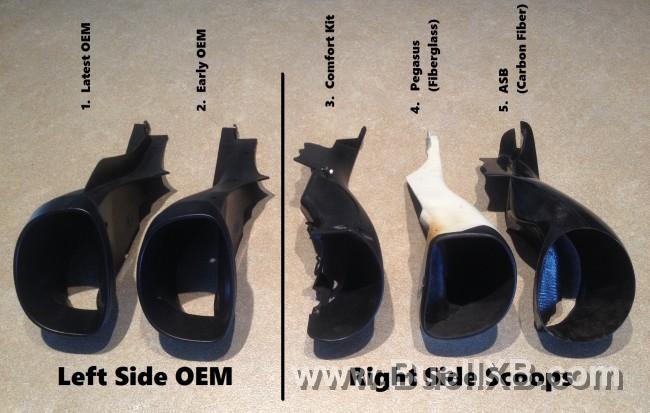

Here are pictures of my OEM left side scoops next to the aftermarket right side scoops.

These are well known aftermarket scoops.

#3 is the optional plastic right side scoop Buell produced with their comfort kit.

#4 is the expensive fiberglass Pegasus scoop that costs over $200.00

#5 is the even more expensive carbon fiber ASB scoop

So on the way home I began thinking of a Buell community project. I have a 3-D printer and the willingness to prototype a matching right side scoop. I do not yet have a 3D scanner to scan in the left side scoop. Therein lies my problem. I need 3-D file of the left side scoop so I can flip it to make a matching right side scoop.

So, here's the challenge part. Here's the chance to be the BAD A$$ and get the recognition for it. It will not cost you anything but time. All you have to do is:

1. Download Google Sketchup.

2. Create or modify an existing computer file that meets all of the dimensions of the left side scoop.

3. Share your file on a public folder so everyone on the forum can use and modify it.

That's it!

Once everyone has worked as a team to come up with a computer file that matches the left side scoop, I will flip it. Then I will print it out to make a right side scoop. The first printed part will go to the member, the forum decides put the most work into the computer file. How will that be figured you ask? Simple we will hold a vote after the part is printed. I am excluded in the running not matter how much I put in. The winner can then do with that part whatever they want. I'll even pay for the shipping to get it to their door. So if you want to be recognized for your work, post here often with your progress so everyone can see it.

I realize once the left side is mirrored it is not going to fit because of the exhaust. So there will be a second maybe a third print made, whatever it takes, and modifications will start to get it to fit. I'll post up pictures of the fitting and take suggestions from the forum on what would look best. Once it's fitted, we all can look for someone who will make a mold of this part and produce it for under $200.00. I'll send that piece anywhere the forum decides it should go at my own expense.

The key is we all get to work as a team and build the scoop we think matches our bikes best. So, who's the BAD A$$ with the skills meet the challenge?

Here are pictures of my OEM left side scoops next to the aftermarket right side scoops.

These are well known aftermarket scoops.

#3 is the optional plastic right side scoop Buell produced with their comfort kit.

#4 is the expensive fiberglass Pegasus scoop that costs over $200.00

#5 is the even more expensive carbon fiber ASB scoop

So on the way home I began thinking of a Buell community project. I have a 3-D printer and the willingness to prototype a matching right side scoop. I do not yet have a 3D scanner to scan in the left side scoop. Therein lies my problem. I need 3-D file of the left side scoop so I can flip it to make a matching right side scoop.

So, here's the challenge part. Here's the chance to be the BAD A$$ and get the recognition for it. It will not cost you anything but time. All you have to do is:

1. Download Google Sketchup.

2. Create or modify an existing computer file that meets all of the dimensions of the left side scoop.

3. Share your file on a public folder so everyone on the forum can use and modify it.

That's it!

Once everyone has worked as a team to come up with a computer file that matches the left side scoop, I will flip it. Then I will print it out to make a right side scoop. The first printed part will go to the member, the forum decides put the most work into the computer file. How will that be figured you ask? Simple we will hold a vote after the part is printed. I am excluded in the running not matter how much I put in. The winner can then do with that part whatever they want. I'll even pay for the shipping to get it to their door. So if you want to be recognized for your work, post here often with your progress so everyone can see it.

I realize once the left side is mirrored it is not going to fit because of the exhaust. So there will be a second maybe a third print made, whatever it takes, and modifications will start to get it to fit. I'll post up pictures of the fitting and take suggestions from the forum on what would look best. Once it's fitted, we all can look for someone who will make a mold of this part and produce it for under $200.00. I'll send that piece anywhere the forum decides it should go at my own expense.

The key is we all get to work as a team and build the scoop we think matches our bikes best. So, who's the BAD A$$ with the skills meet the challenge?