For anyone who knows more then me OR has done this themselves (Dean) I would like to make sure i am understanding how to do it right before I mess anything up.

From the picture am i understanding this all right?

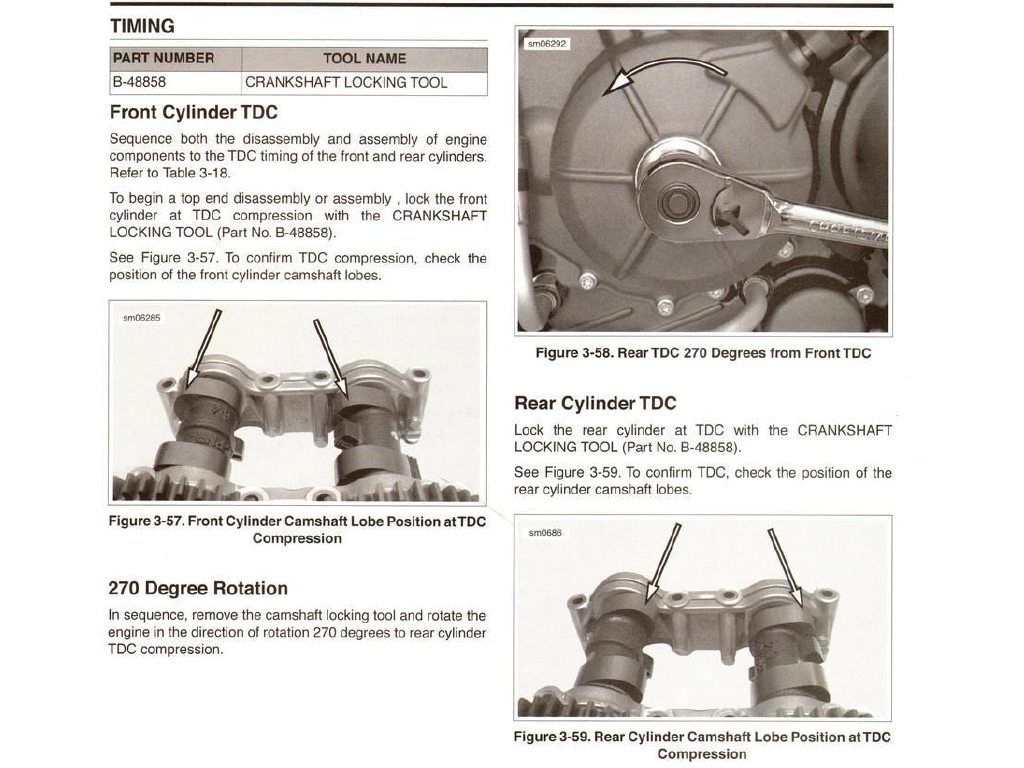

Note: The picture is of the rear head.

Also the manual states the min and max tolerance the valves should be, but what is best to be closet to?

I would assume the min. I mainly need to know cause my feeler gauge doesnt have the exact tolerance but has ones that fit in the min-max tolerance.

Also the book confuses me on the shims, arent we able to adjust the shims on the bike with a screw or should i actually have a set of shims to put in place.

For anyone who response thank you. I want to make sure I dont **** anything up too bad.

From the picture am i understanding this all right?

Note: The picture is of the rear head.

Also the manual states the min and max tolerance the valves should be, but what is best to be closet to?

I would assume the min. I mainly need to know cause my feeler gauge doesnt have the exact tolerance but has ones that fit in the min-max tolerance.

Also the book confuses me on the shims, arent we able to adjust the shims on the bike with a screw or should i actually have a set of shims to put in place.

For anyone who response thank you. I want to make sure I dont **** anything up too bad.