rockin4runner

Active member

- Joined

- Dec 20, 2014

- Messages

- 43

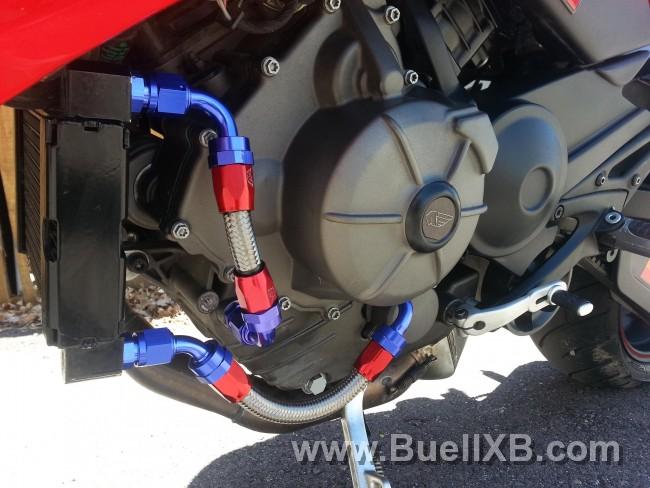

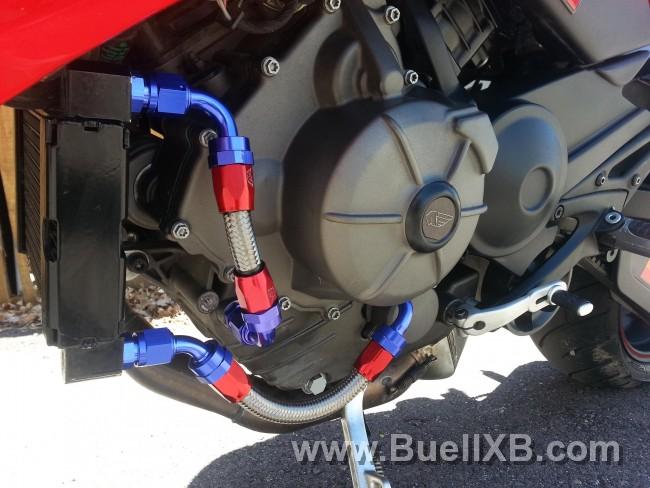

Hello, The other day I laid my bike down and it cracked the lower oil line [sad]. After doing some research there are a few people that have replaced there OEM lines with still braided lines. The closes thing I could find to a write up on this mod was part numbers so I thought I would add my 2 cents to this site and do a write up. On a scale of difficulty from 1-5 (5 being most difficult) I would rate this mod at a 2; total time 1 hour; total parts cost $103.

I ordered all the parts from Jegs and they also have black fittings and black hose if you want to go that route.

4x Flare Reducer, -6AN to -8AN, 555-100212

3x 90° Max Flow Swivel Hose End, -8AN, 555-100022

1x 45° Max Flow Swivel Hose End, -8AN, 555-100012

1x Pro-Flo 200 Series Stainless Steel Braided Hose, -08AN, 555-100920

Remove the OEM lines.

Remove OEM oil line fittings.

Notice - oil line fittings are not torqued down super tight.

Remove OEM o-ring from removed fittings

Place OEM o-ring only -6 to -8 reducer fitting.

Wrap fitting with teflon tape to be safe for leaks.

Install reducer fittings.

Notice - Stator cover has been unbolted from engine. this is not necessary.

- DO NOT OVER TIGHTEN FITTINGS.

Cut two peaces of hose at 2.75" and 6".

Notice - I am using a cut off wheel, I think this is the best tool the cut the braided line.

- Wrap hose with electrical tap before cutting. This will help the hose from fraying (do not remove electrical tape)

Assemble hoses by pushing the red hose nut onto the hose, spray some WD-40 onto the blue fitting threads and into the hose, thread blue fitting onto red hose nut. Once assembled be sure to spray the inside of the hose with brake cleaner.

Note : The 6" hose uses one 45degree fitting on one end and a 90degree fitting on the other. The 2.75" used 2 90 degree fittings

Install hoses onto cooler and engine.

I ordered all the parts from Jegs and they also have black fittings and black hose if you want to go that route.

4x Flare Reducer, -6AN to -8AN, 555-100212

3x 90° Max Flow Swivel Hose End, -8AN, 555-100022

1x 45° Max Flow Swivel Hose End, -8AN, 555-100012

1x Pro-Flo 200 Series Stainless Steel Braided Hose, -08AN, 555-100920

Remove the OEM lines.

Remove OEM oil line fittings.

Notice - oil line fittings are not torqued down super tight.

Remove OEM o-ring from removed fittings

Place OEM o-ring only -6 to -8 reducer fitting.

Wrap fitting with teflon tape to be safe for leaks.

Install reducer fittings.

Notice - Stator cover has been unbolted from engine. this is not necessary.

- DO NOT OVER TIGHTEN FITTINGS.

Cut two peaces of hose at 2.75" and 6".

Notice - I am using a cut off wheel, I think this is the best tool the cut the braided line.

- Wrap hose with electrical tap before cutting. This will help the hose from fraying (do not remove electrical tape)

Assemble hoses by pushing the red hose nut onto the hose, spray some WD-40 onto the blue fitting threads and into the hose, thread blue fitting onto red hose nut. Once assembled be sure to spray the inside of the hose with brake cleaner.

Note : The 6" hose uses one 45degree fitting on one end and a 90degree fitting on the other. The 2.75" used 2 90 degree fittings

Install hoses onto cooler and engine.