motoqueiro

Well-known member

- Joined

- Jul 3, 2011

- Messages

- 320

OK

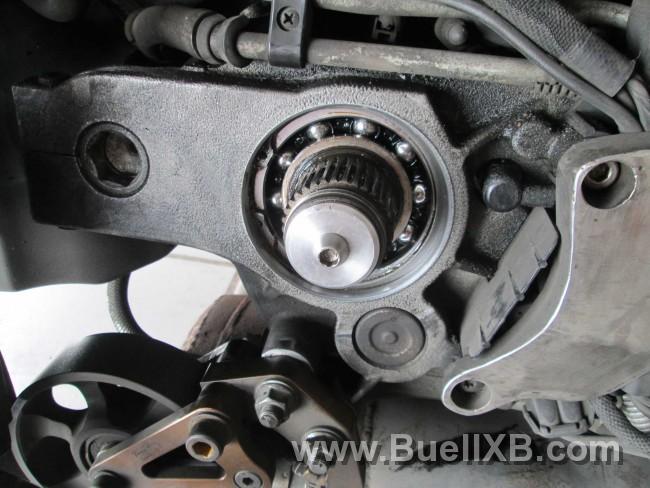

I'll post the work I've done today, after I realize, a week ago, the bearing was about to go bummm

It's a 10 year old bearing with 140000 km in it on an every day ride bike

remove belt

with a special home made tool, lock the pulley and remove the locking plate and pulley "left" nut

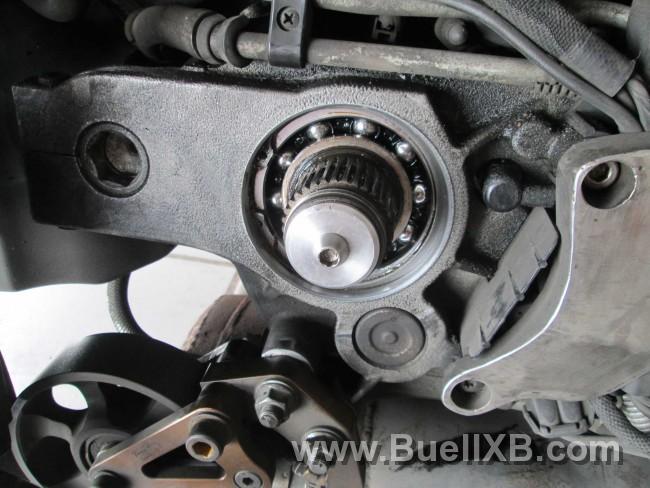

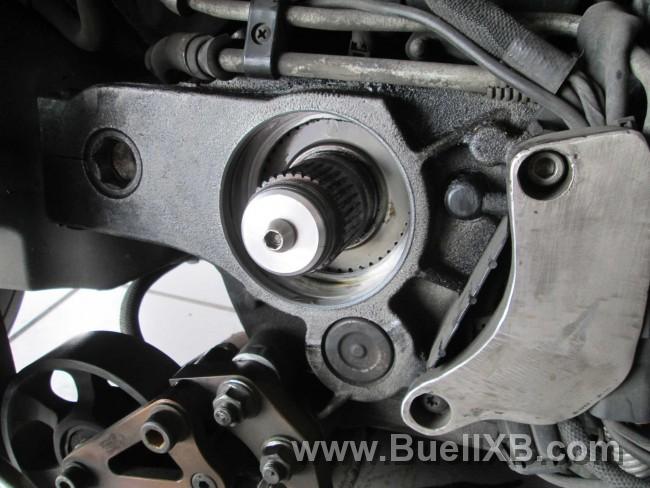

Remove pulley, pulley spacer, oil seal, and retaining ring

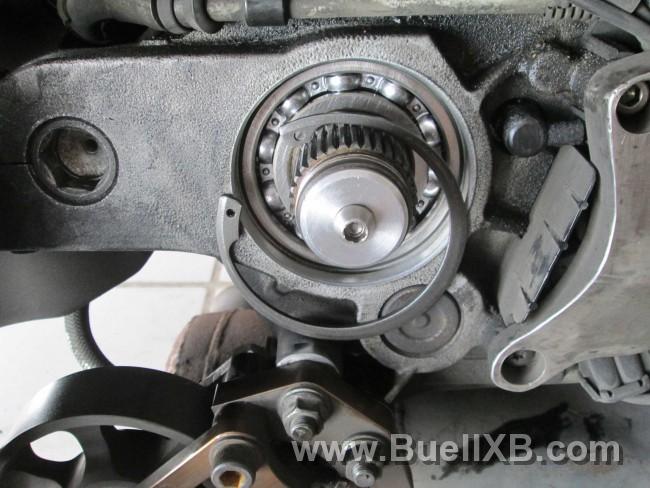

Then remove the bearing, I've made a grab so to go in the bearing and be able to pull it out

yank it out

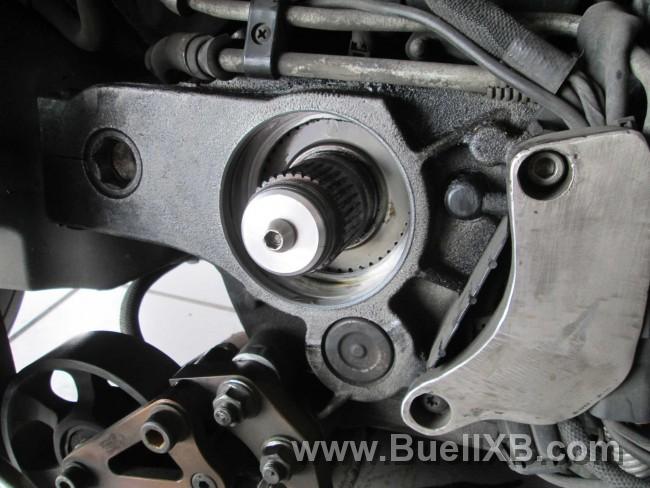

now for the new bearing

did a pusher for it to

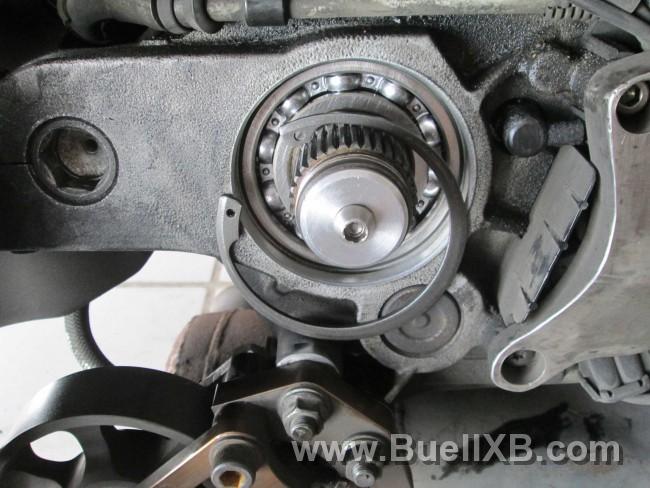

instal the retaining ring the quad seal oil seal pulley spacer and pulley

using the locking tool, fit the left thread nut and tight it good, fit the locking plate and tight the two bolts

and finally fit the belt and your done

can go and relax now

I'll post the work I've done today, after I realize, a week ago, the bearing was about to go bummm

It's a 10 year old bearing with 140000 km in it on an every day ride bike

remove belt

with a special home made tool, lock the pulley and remove the locking plate and pulley "left" nut

Remove pulley, pulley spacer, oil seal, and retaining ring

Then remove the bearing, I've made a grab so to go in the bearing and be able to pull it out

yank it out

now for the new bearing

did a pusher for it to

instal the retaining ring the quad seal oil seal pulley spacer and pulley

using the locking tool, fit the left thread nut and tight it good, fit the locking plate and tight the two bolts

and finally fit the belt and your done

can go and relax now