lawdog

Well-known member

So I decided to build my own exhaust but wanted to do something a little different. I love the deep rumble of Rush Baffles so that is the sound I am going for. Low, deep, and mellow.

I decided to go with a set of 2 inch Rush Baffles and fiberglass packing around the baffles. I like fiberglass because it gives a smooth mellow tone. No tinny, or metallic noise. (Think chambered Flowmaster muffler verse sound verse Dynomax packed muffler.)

First I bought a used muffler for $25 on craigslist. I then cut it open, removed the rear chamber, and removed the 3 inner chamber pipes. Next I took the two baffles, grinded the welds off, and took each end cap off. Then I had my welder weld in the baffles and weld a plate over the center hole I then wrapped the baffles with the Rush factory packing then held it in place with wire.

I then packed one sheet of the MSR packing around both baffles to fill up the muffler.

Next I tacked it shut for the welder.

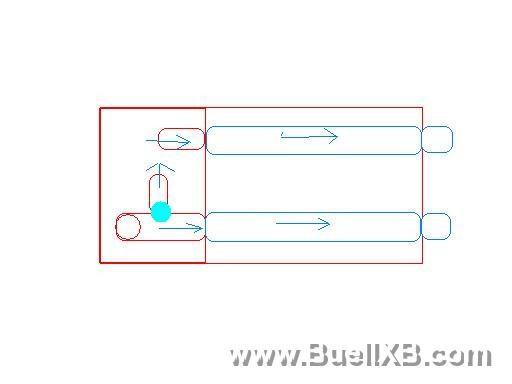

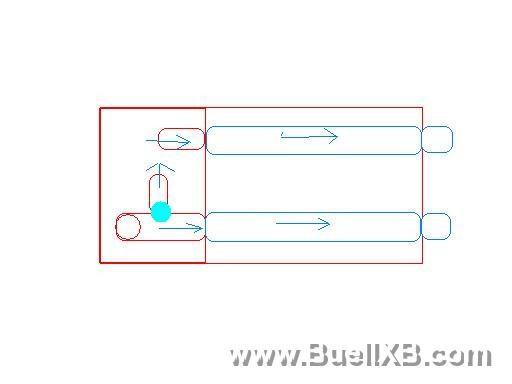

Here is a rough sketch of the plan.

Normal cruising the exhaust goes through the left baffle (driver side birds eye view) and dumps out. When the exhaust valve opens the extra exhaust flows out both baffles. I may play around with the valve and/or welding in a washer to make sure I don't loose any midrange torque.

Here is an inside pic of the baffles. You can see the louvers.

So then I had my welder button it up for me and I painted it with 2000' high temp gloss black. I thought about grinding the welds down to make them nice and pretty but really, who sees the top of the muffler. I also had him install two chrome turndowns which run $10 each at Autozone. Here are the finished pics.

Costs:

$25 used muffler

$64 baffles

$15 packing

$35 welder costs

$20 chrome tips

$159 Total Costs

A couple additional things worth mentioning. I bought three packs of exhaust packing and only ended up using one. I have two left over if anybody needs any. Also if you wanted to save money you could punch holes in the current pipes instead of welding in new baffles. Granted thats alot of holes to drill and I hope you have a drill press and a free afternoon.

I am working a bunch of OT this weekend but I hope to have the muffler back on the bike in a couple days. Once I get it back on and do some tuning I will report back.

Cheers!

Brett

09 XB12R

I decided to go with a set of 2 inch Rush Baffles and fiberglass packing around the baffles. I like fiberglass because it gives a smooth mellow tone. No tinny, or metallic noise. (Think chambered Flowmaster muffler verse sound verse Dynomax packed muffler.)

First I bought a used muffler for $25 on craigslist. I then cut it open, removed the rear chamber, and removed the 3 inner chamber pipes. Next I took the two baffles, grinded the welds off, and took each end cap off. Then I had my welder weld in the baffles and weld a plate over the center hole I then wrapped the baffles with the Rush factory packing then held it in place with wire.

I then packed one sheet of the MSR packing around both baffles to fill up the muffler.

Next I tacked it shut for the welder.

Here is a rough sketch of the plan.

Normal cruising the exhaust goes through the left baffle (driver side birds eye view) and dumps out. When the exhaust valve opens the extra exhaust flows out both baffles. I may play around with the valve and/or welding in a washer to make sure I don't loose any midrange torque.

Here is an inside pic of the baffles. You can see the louvers.

So then I had my welder button it up for me and I painted it with 2000' high temp gloss black. I thought about grinding the welds down to make them nice and pretty but really, who sees the top of the muffler. I also had him install two chrome turndowns which run $10 each at Autozone. Here are the finished pics.

Costs:

$25 used muffler

$64 baffles

$15 packing

$35 welder costs

$20 chrome tips

$159 Total Costs

A couple additional things worth mentioning. I bought three packs of exhaust packing and only ended up using one. I have two left over if anybody needs any. Also if you wanted to save money you could punch holes in the current pipes instead of welding in new baffles. Granted thats alot of holes to drill and I hope you have a drill press and a free afternoon.

I am working a bunch of OT this weekend but I hope to have the muffler back on the bike in a couple days. Once I get it back on and do some tuning I will report back.

Cheers!

Brett

09 XB12R