I have been riding for years. Tons of different bikes. I wrench all my own bikes. If I can't figure something out I can always depend on a forum or a good service manual. Not with this 2003 XB9R.

What a friggin nightmare. No wonder I got it so cheap. Its literally a media blackout when it comes to the complete teardown of one of these motors.

I guess when the transmissions goes on one of these bikes you just junk the motor and get a new one.

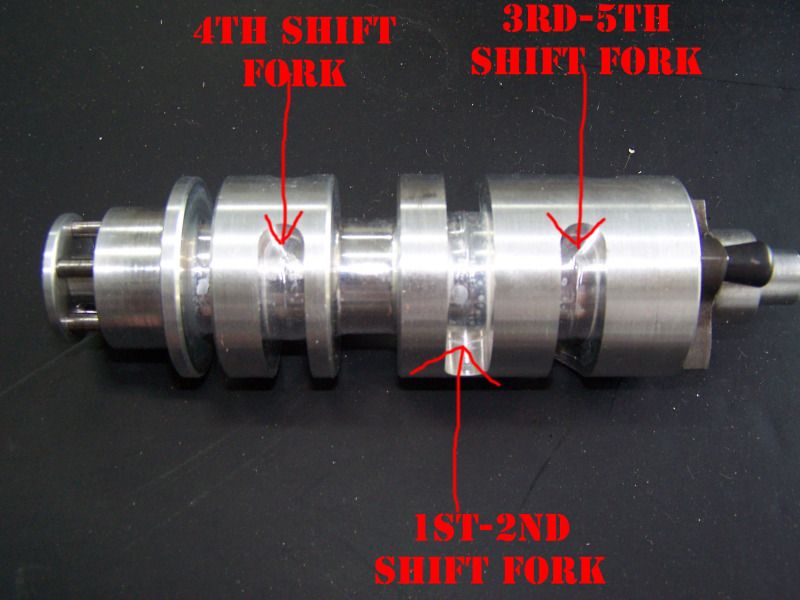

I feel like Indiana Jones exploring the Buell Mystery when it comes to a motor tear down. Just needed to rant a little. Stupid transmission fork drum installation is screwing up my entire riding season.

Bummer. Are there any Buell owners on this forum that have done more than cosmetics on their bikes?

I would think that guys who track race their bikes must be familiar with teardowns and transmission work. I guess none of them are members of this forum.

What a friggin nightmare. No wonder I got it so cheap. Its literally a media blackout when it comes to the complete teardown of one of these motors.

I guess when the transmissions goes on one of these bikes you just junk the motor and get a new one.

I feel like Indiana Jones exploring the Buell Mystery when it comes to a motor tear down. Just needed to rant a little. Stupid transmission fork drum installation is screwing up my entire riding season.

Bummer. Are there any Buell owners on this forum that have done more than cosmetics on their bikes?

I would think that guys who track race their bikes must be familiar with teardowns and transmission work. I guess none of them are members of this forum.