Thanks man. I never heard of that stuff. I'll give it a try one of these days.

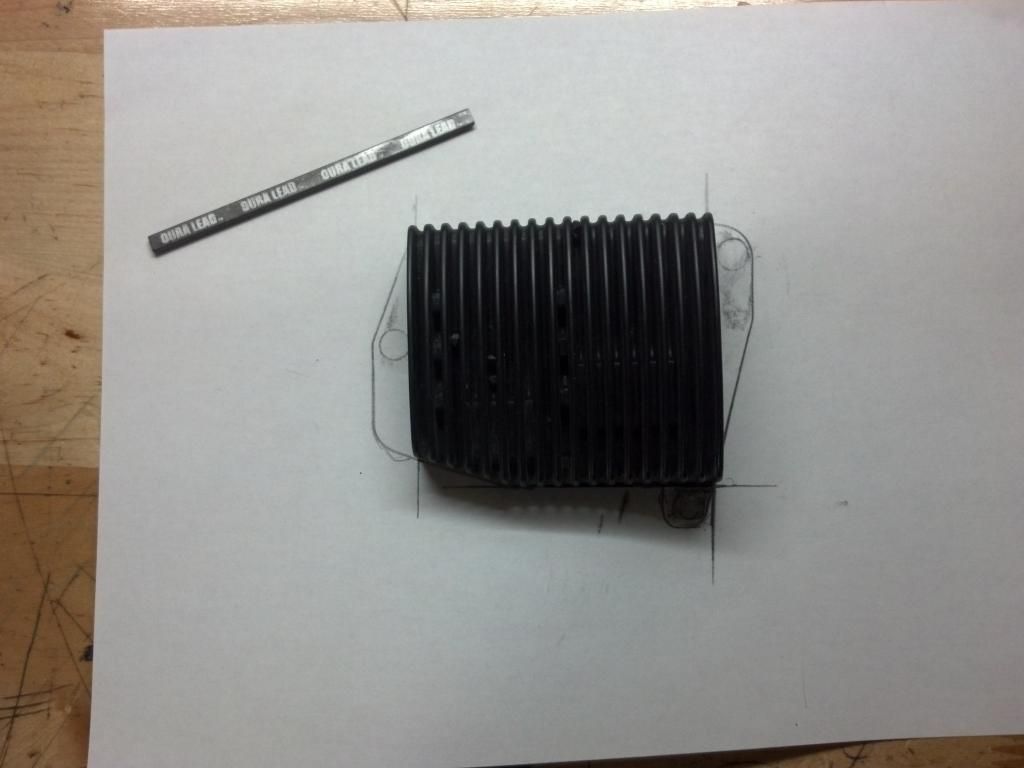

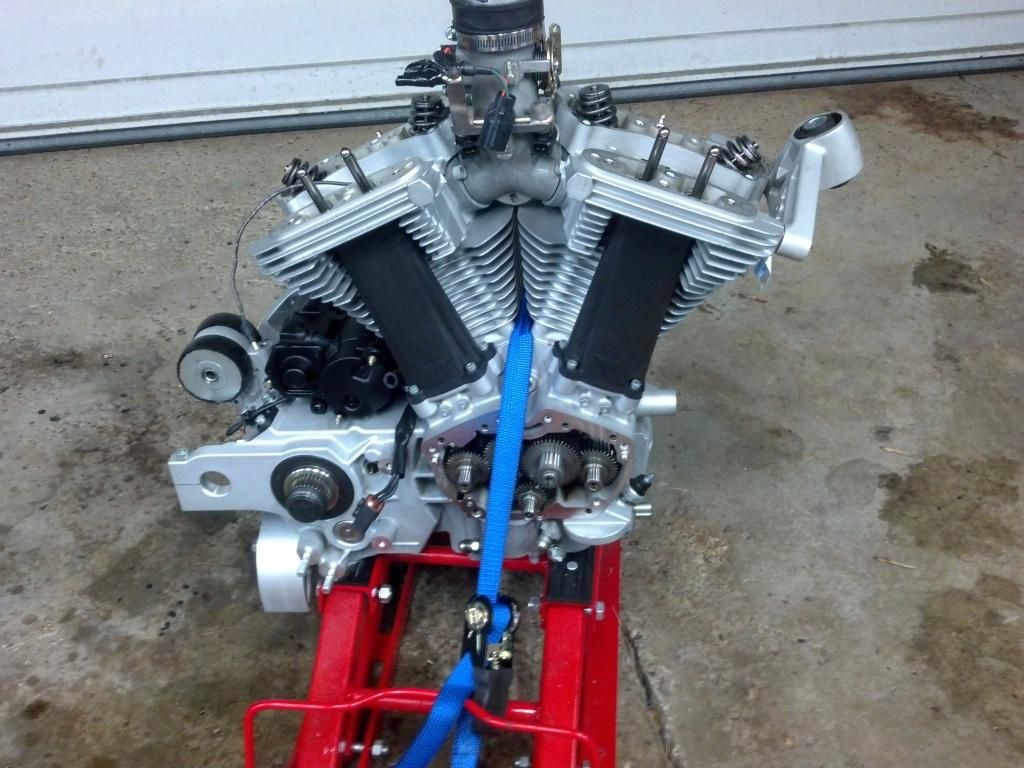

Now that the frame is getting ready for powder coat I need to strip off the VIN sticker. I want to reuse it. I'll put it on the subframe once its powder coated under the seat.

To do this I have a method. It required some adjustments at the Buell VIN sticker is real thin.

I used a heat gun to warm the sticker. Because its mounted to a rather large slab of aluminum it will take some serious heat. I keep warming it up until it is almost too hot to touch. Then I let it cool down. I repeat this 2 or three times. Then when I feel the sticky is loosened I heat it back up to the "almost too hot to touch". Then its time to peel it off.

I start a corner with a small hobby exacto knife. Once I get enough to grab it I slowly start to peel it up. I try to be real careful not to stretch it too much. Slow and steady. Don't worry about finger prints, just don't let the sticker stick to its self.

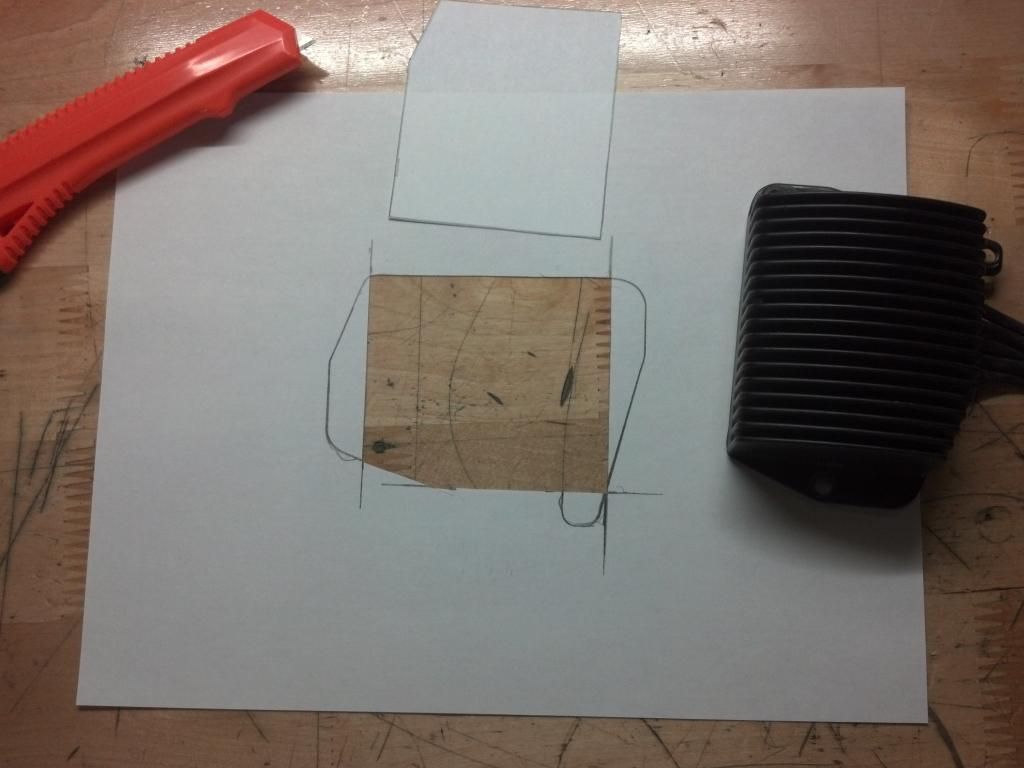

When I get it off it is a bit deformed. That doesn't matter (with in reason) and can be fixed. First I need to remove the adhesive. I spray a piece of waxed paper with WD40 and set the sticker sticky side down in the oil.

I slide it around on the waxed paper for a while. Then flip it over and spray it directly with the WD40. I do this until it seems that all the stickum is off.

Now I take it to the kitchen sink. Keep in mind that now that the sticker isn't stuck to a huge aluminum heat sink it no longer is able to take much heat. I set the faucet to warm. Too hot will shrivel it up. I use a little Dawn dish soap and WARM water. As I clean it up I gently stretch it back into shape adjusting the water temp as needed. With my fingers I stretch it back into shape. When it is good I hit it with cold water to set the shape.

I set it on a new piece of waxed paper. I like to pour a little water on the situation and shape up the sticker like you would window tint. Once I'm happy with it I fold the waxed paper over the top and put it in a heavy book. It will stay there until ready to reinstall.

When I reattach it I'll use some new clear adhesive and spread it flat with a squeegee. It's almost like a super thin sheet of rubber and I will be able to shape it nice and straight.

I took a picture of the removed sticker. It's set on the waxed paper which sets on a white towel.