You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacing intake gaskets (DIY TUTORIAL)

- Thread starter MrDrumngun

- Start date

Help Support Buellxb Forum:

Hello. I have 2009 Buell XB12Scg with 16500 miles.

Today I started to replace the intake manifold gaskets. Here is what I found in the intake manifold. Thick layer of dirt on the walls and the valves! Is this something I should care about or just ignore it? Is it normal?

I'm not sure if you can even recognize the valves under those dirt. I believe these valves totally lost their flow characteristics. I touched the dirt by fingers and it feels hard as rock. I think the dirt does not let the valves close the holes firmly and fire goes back in the intake manifold trough the gaps and because of this the intake manifold and the butterfly valve are full of dirt.

Today I started to replace the intake manifold gaskets. Here is what I found in the intake manifold. Thick layer of dirt on the walls and the valves! Is this something I should care about or just ignore it? Is it normal?

I'm not sure if you can even recognize the valves under those dirt. I believe these valves totally lost their flow characteristics. I touched the dirt by fingers and it feels hard as rock. I think the dirt does not let the valves close the holes firmly and fire goes back in the intake manifold trough the gaps and because of this the intake manifold and the butterfly valve are full of dirt.

Last edited:

rchuff

Well-known member

And that is why I run fuel treatment every other tank or 2. Might be overkill but worth it I think. Looks like burnt sugar. Did you do a breather reroute?

Last edited:

There is no breather reroute, all is stock. I closed the valves, sprayed brake cleaner inside the chambers, covered the holes by a rag and let it soak overnight, but at the morning I notices it does not help to remove or loosen the dirt. Also I tried to loosen the dirt by a plastic brush with no big success. Tonight I'm going to buy a Sea-Foam engine cleaner and intake valve cleaner and try to apply them.

Last edited:

rchuff

Well-known member

You should think of doing a breather reroute so you are not sucking the crankcase crap down in your throttle body.

I tried to spray CRC valve cleaner in the chamber and pour Sea Foam. Nothing helps. It looks like those products work only when engine are working. I'm going to assemble the intake back and try Sea Foam according the instruction. Brake cleaner gives the best result for manual cleaning by the way.

Last edited:

You should think of doing a breather reroute so you are not sucking the crankcase crap down in your throttle body.

Breather reroute is bad idea. First of all ECM is adjusted to correct fuel mixture according intake air temperature sensor. When you replace the hoses from the intake chamber you significantly change temperature in the chamber and it causes wrong temperature reading because ECM assumes that there are additional temperature due to hoses from the engine, wrong fuel mixture causes power loss and fuel economy loss. Another issue is when you remove hoses there in no oil vapor in the chamber anymore and it causes than the air filter gets dry and engine sucks dust and dirt from the air. Plus with no oil vapor the valves and the top area of piston work with no lubrication anymore. I would not recommend you to reroute the hoses.

Last edited:

user_deleted

Well-known member

Breather reroute is bad idea. First of all ECM is adjusted to correct fuel mixture according intake air temperature sensor. When you replace the hoses from the intake chamber you significantly change temperature in the chamber and it causes wrong temperature reading because ECM assumes that there are additional temperature due to hoses from the engine, wrong fuel mixture causes power loss and fuel economy loss. Another issue is when you remove hoses there in no oil vapor in the chamber anymore and it causes than the air filter gets dry and engine sucks dust and dirt from the air. Plus with no oil vapor the valves and the top area of piston work with no lubrication anymore. I would not recommend you to reroute the hoses.

absolutely positively 100% incorrect info on all counts. but then again i really don't know all that much about these bikes so disregard my opinion.

Last edited:

BuellyBagger

Well-known member

That escalated quickly! The only down fall to a breather reroute is finding another place to dump you're crank case vomit! Granted it should be tiny new born spit up, not me on a hard tequila night!lol. Just in case any newbs didn't catch John's sarcasm. ....

- Joined

- Jan 15, 2016

- Messages

- 851

Actually there can be unburned fuel vapor, moisture, soot, and other combustion junk. Definitely unwanted stuff. O yeah.. and oil vapor

rchuff

Well-known member

TEABAG, you should not be giving any advice on this forum because you my sir are out of your mind!!!!!!

Last edited:

rchuff

Well-known member

Well everything he has engineered on here has gone to sh-t !!!!!!!!! NEED I SAY MORE! O I get it, an engineer of a train wreck !

Last edited:

Tbone

Well-known member

I attempted to replace the intake seals on my own w/o engine rotation, noticed a leak in the rocker gasket, so took it into Harley Davidson in Alan Tx and they ended up replacing the Rocker Gaskets, Intake Seals, and the ECM. The mechanic said I had the cleanest valves and ports he has seen in a long time, believe me I run a lot of fuel system cleaner such as Gumout fuel system cleaner, and other Wally World brand.

great write-up...great pics.

leaking intake gaskets? trust me......you'll know it if and when it happens to your buell. performance is terrible and idle speed all over the map.

Not necessary. Motorcycle can perform just fine. But if there is a leakage check engine light can appear with error 34 IAC too low.

BuellyBagger

Well-known member

Not necessary. Motorcycle can perform just fine. But if there is a leakage check engine light can appear with error 34 IAC too low.

How is an unknown amount of EXTRA air being sucked in to each combustion cycle ok?

And pre IAC bikes don't idle right with a leak

I have error 34 and probably throttle body leakage, so I replaced gaskets today without engine rotation on 2009 Buell XB12 Scg.

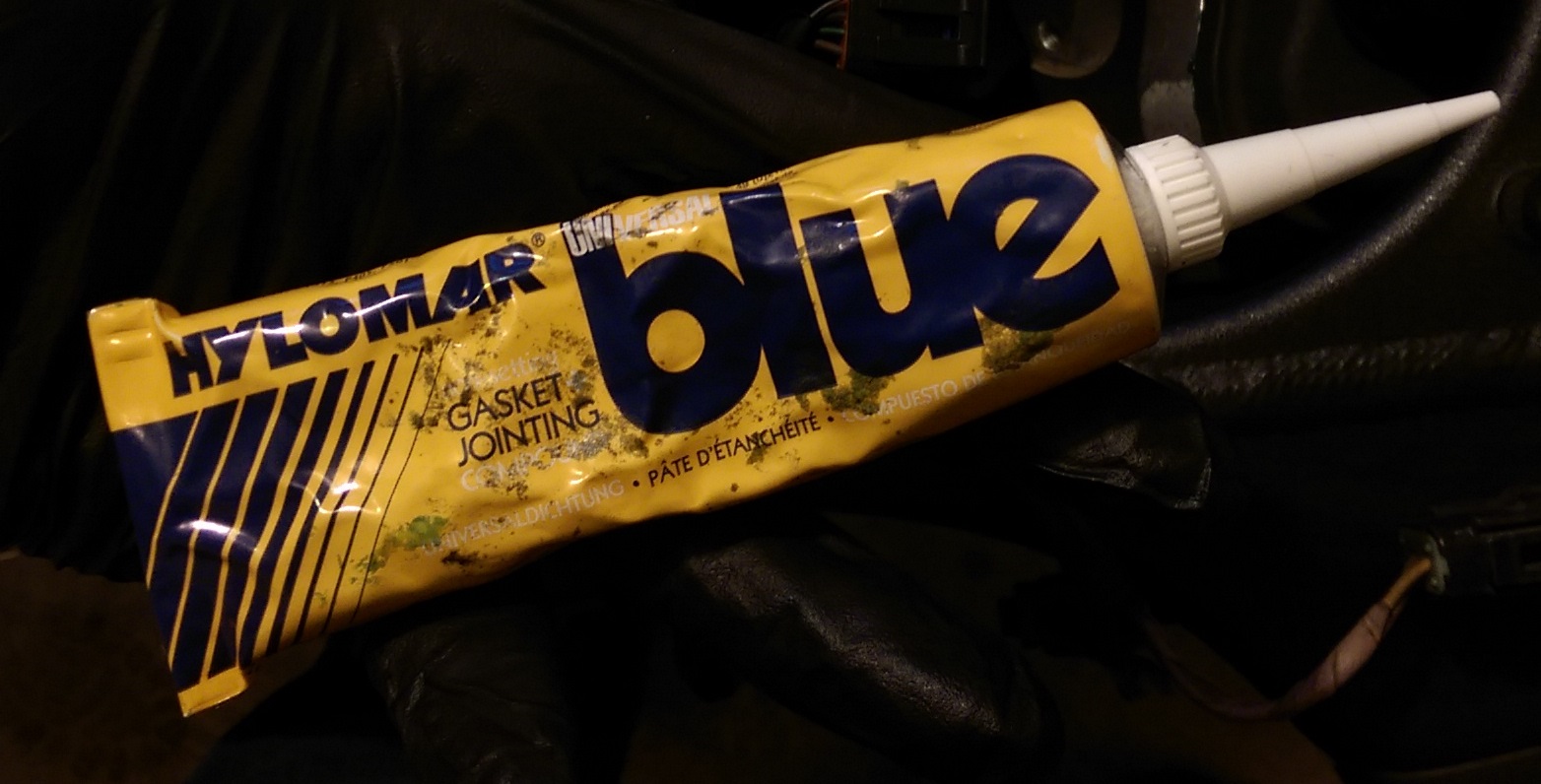

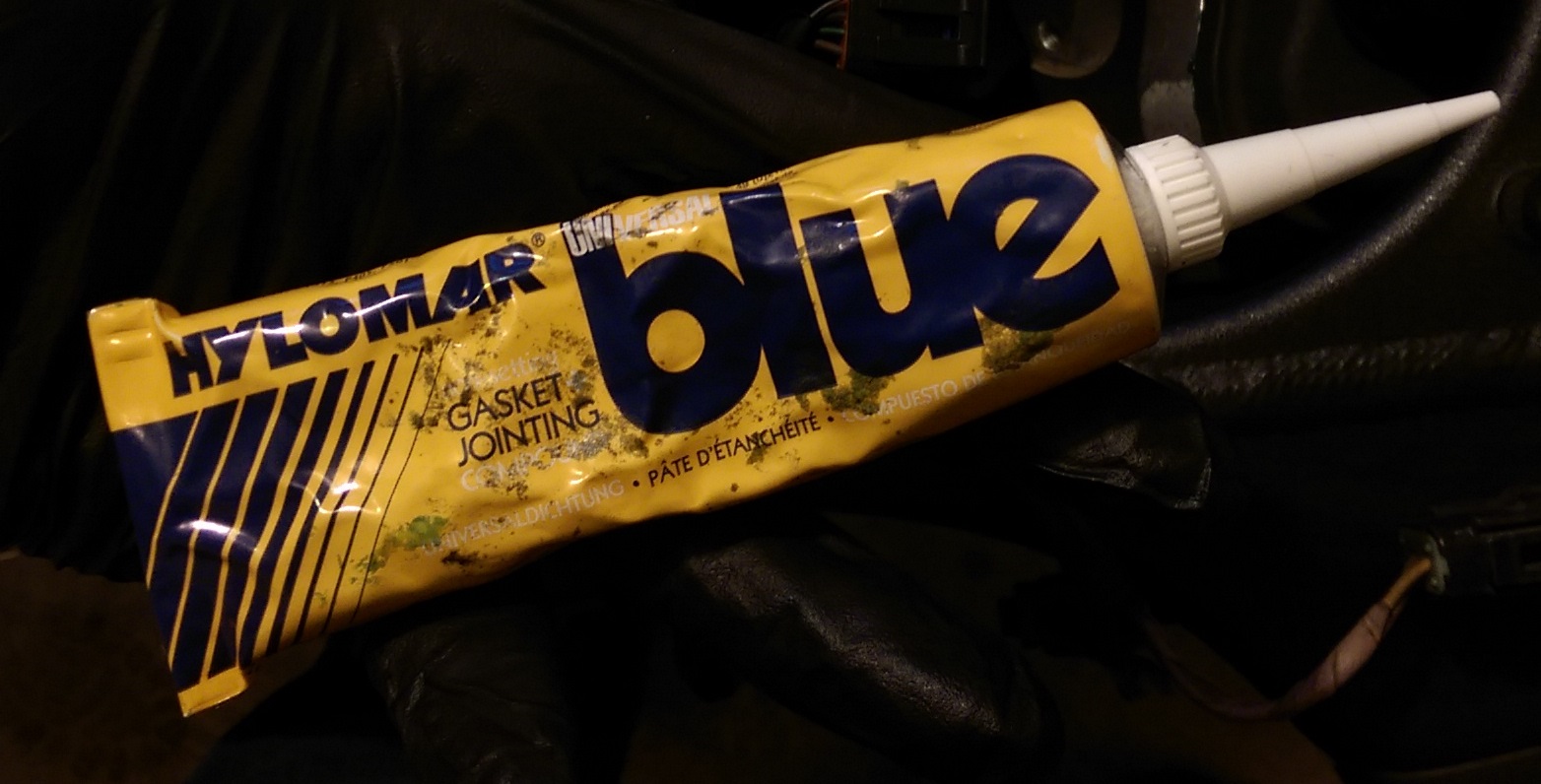

I bought washers for 5/16 (M8) screws in O'Reilly Auto Parts Store (they have thickness about 1.7 mm). Prepared Intake Blue Games Gaskets and Hylomar Blue.

Cleaned surfaces and applied Hylomar on engine intake surfaces

Applied Hylomar on internal surface of gaskets and side surface of intake manifold

Applied Hylomar on flange surface of the gaskets

Assembled everything back with those 5/16 (M8) washers to space the flanges to prevent flanges bending

I also replaced IAC housing gasket, IAC O-ring, Ingectors O-rings and installed new TPS. If this will not fix leakage and error 34 I have no idea what else I can do with this motorcycle. Maybe it also can sucks air through the valves seals from inside the engine rockerbox and through the throttle baffle bearing on the throttle rocker side (I replaced TPS on opposite side of the throttle baffle so opposite side bearing should not leak I believe)?

I bought washers for 5/16 (M8) screws in O'Reilly Auto Parts Store (they have thickness about 1.7 mm). Prepared Intake Blue Games Gaskets and Hylomar Blue.

Cleaned surfaces and applied Hylomar on engine intake surfaces

Applied Hylomar on internal surface of gaskets and side surface of intake manifold

Applied Hylomar on flange surface of the gaskets

Assembled everything back with those 5/16 (M8) washers to space the flanges to prevent flanges bending

I also replaced IAC housing gasket, IAC O-ring, Ingectors O-rings and installed new TPS. If this will not fix leakage and error 34 I have no idea what else I can do with this motorcycle. Maybe it also can sucks air through the valves seals from inside the engine rockerbox and through the throttle baffle bearing on the throttle rocker side (I replaced TPS on opposite side of the throttle baffle so opposite side bearing should not leak I believe)?

Last edited:

Thank you.

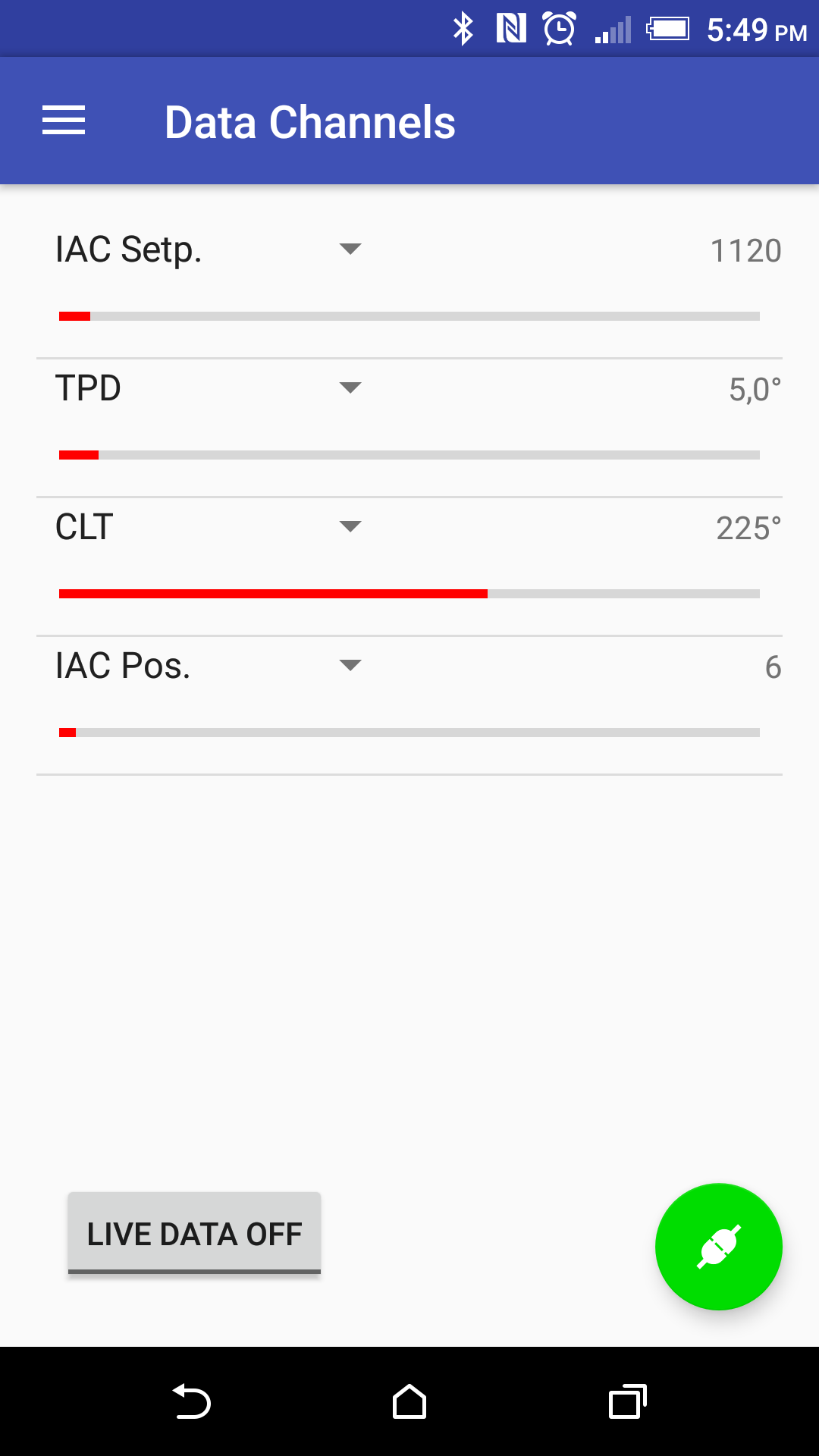

I ran ECM Droid today with hot engine, and it showed about 10% IAC Position at rear cylinder temperature 200 C at idle 1120 RPM at closed throttle.

When temperature raised to 225 C the IAC Position dropped to 5-6% at idle 1120 RPM at closed throttle. I was not able to achieve check engine light at this conditions but as I understand 6% is very small gap and probably this is close to the IAC limit and close to code 34 when idle RPM will be out of ECM control.

Can anyone confirm normal IAC position at idle speed on healthy motorcycle on hot engine?

The initial IAC position is 40% when I open the throttle.

The guy on the video below says IAC should be about 30% at closet throttle at idle RPM, and 20% IAC means the hole is completely closed for a Ford car. I believe IAC on Buell should show 0% for completely closed hole?

https://youtu.be/ayjhL9jpFH8?t=309

So I see two major issues: throttle body has leakage somewhere, or electric malfunction so real IAC position does not match the IAC position ECM gets.

Throttle leakage can happen due to a few reasons: bad seal between engine and throttle body gaskets, bad seal in fuel rail gasket, bad seal at injectors lower o-rings, bad seal in IAC plunger hole, excessively worn or damaged IAC plunger or damaged IAC hole so IAC can not stop at the hole bottom completely and stops earlier so it causes wrong IAC calibration and bigger gap between hole and IAC tip.

Electric malfunction can happen due to electric noises or damaged wires, so stepper motor yields steps and after some time real IAC plunger position does not match virtual IAC position in ECM. Or there is program malfunction in ECM causing the difference between real IAC position and virtual IAC position.

If this is leakage it is probably very small due to IAC is able to compensate it, but it looks like it is at the very limit of IAC capabilities so sometimes check engine light appears. And it appears only when engine temperature is high.

Another possible source of air leakage is valves seals, probably after I cleaned the valves they started to pass more air from rocker box trough the seals.

OK, I have assembled everything back and tested motorcycle with ECM Droid again with fresh blue gaskets and Hylomar combo. Now IAC position is about 8-10 at temperature 225 C which is slightly higher than before. I do not know if it is normal IAC position at this temperature or not. Will see if error 34 will appear again.

Last edited:

Similar threads

- Replies

- 0

- Views

- 3K

- Replies

- 4

- Views

- 11K

- Replies

- 32

- Views

- 11K