Measured coils resistance on the new IAC, it shows 56 Ohm for both coils. So it looks like the old unit coils resistance is probably OK.

Also both new and old IACs moves the same way when I turn engine switch ON.

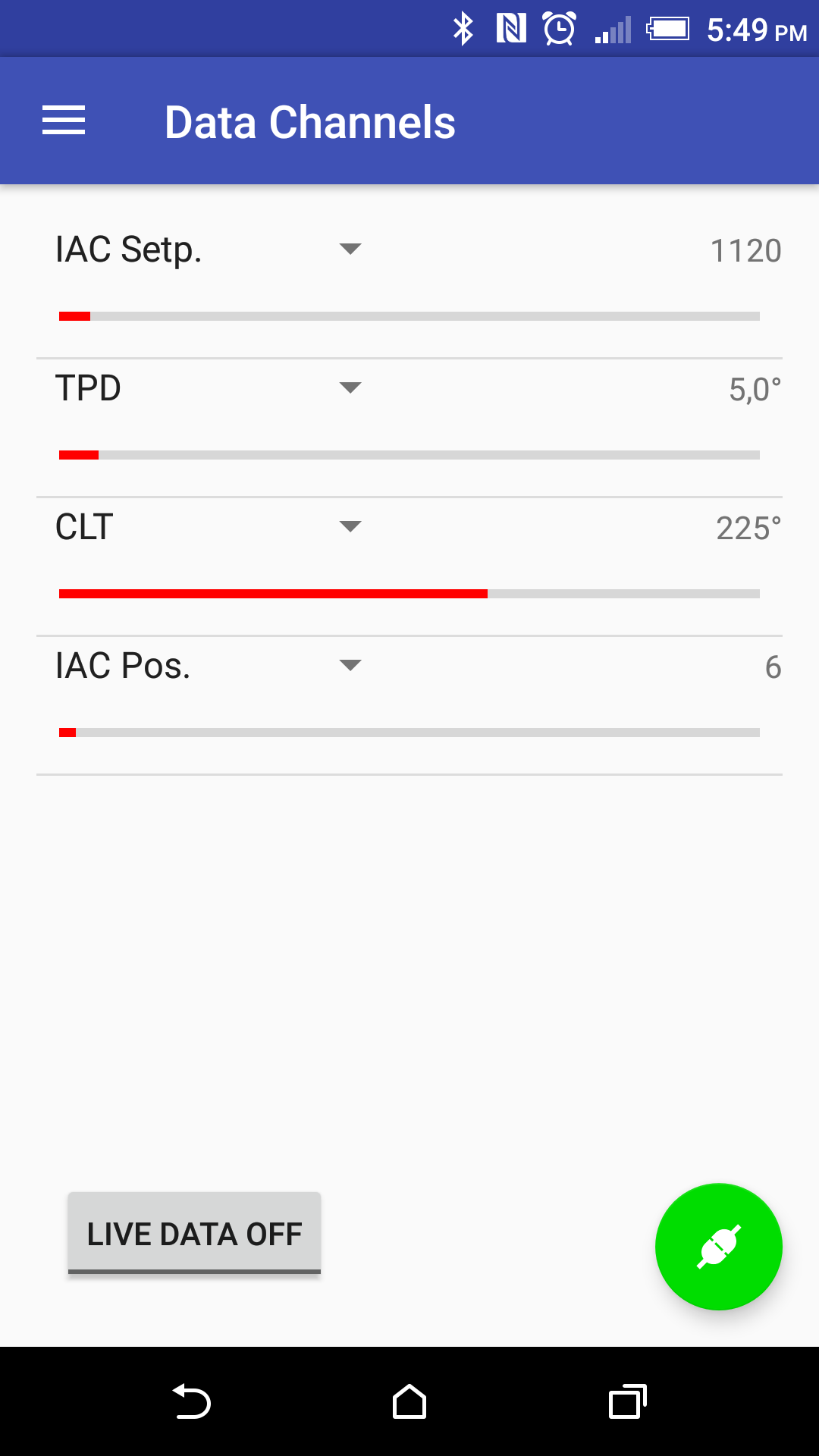

If I press "Active Intake Test" in the ECM Droid should it move the IAC plunger? I press it and nothing happens with both new and old IACs, they do not move.

It looks like the IAC on the Buell performs self-calibrating each time you turn ON the engine switch. Once you have turned engine switch ON IAC moves plunger down more than moves it up and it does not put big force on the plunger, so plunger touches the hole surface, then yield steps on stepper motor and then moves back to particular distance. So that is why you want to wait until check engine lite came OFF and start engine only after this, because of IAC performs calibrating process, you do not want to start engine instantly before it will have finished this process.

Also both new and old IACs moves the same way when I turn engine switch ON.

If I press "Active Intake Test" in the ECM Droid should it move the IAC plunger? I press it and nothing happens with both new and old IACs, they do not move.

It looks like the IAC on the Buell performs self-calibrating each time you turn ON the engine switch. Once you have turned engine switch ON IAC moves plunger down more than moves it up and it does not put big force on the plunger, so plunger touches the hole surface, then yield steps on stepper motor and then moves back to particular distance. So that is why you want to wait until check engine lite came OFF and start engine only after this, because of IAC performs calibrating process, you do not want to start engine instantly before it will have finished this process.

Last edited: